2025 AIChE Annual Meeting

(620f) E-Textile Sensors Enhanced By Low-Melting Temperature Nano-Solders for Simultaneous Detection of Multiple Hazardous Gases

Authors

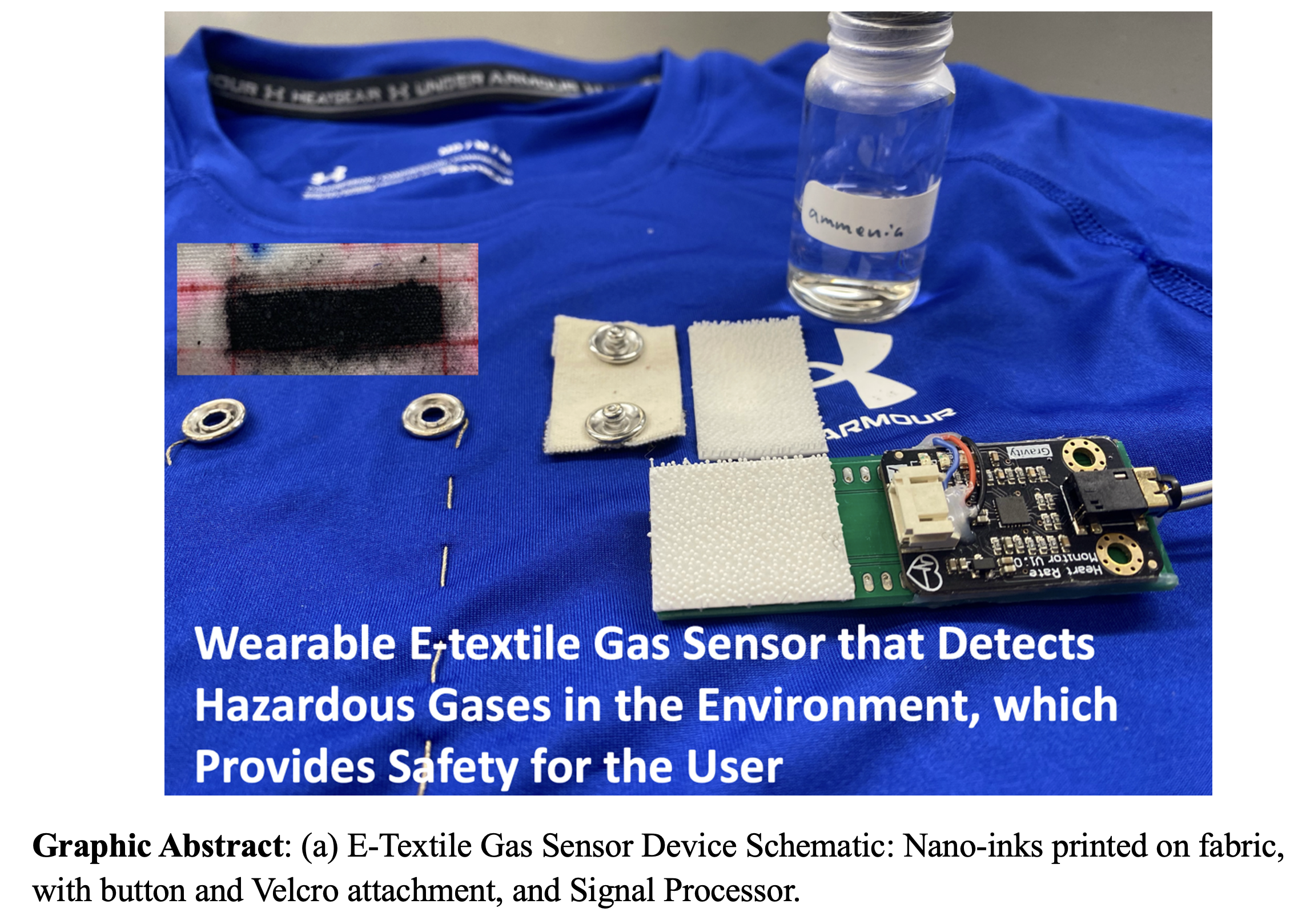

This study aims to develop an E-textile sensor that is easily fabricated, cost-effective, portable, operates at room temperature, and integrates seamlessly into the user's clothing, providing real-time notifications of multiple nearby hazardous gas vapors. To ensure accurate concentration measurements, commercially purchased gas sensors are used for calibration and are compared with theoretical values. Gas-sensitive nanoparticles, such as graphene oxide for ammonia, will be selected as the working materials and screen-printed onto the fabric. Metal nanoparticles will be incorporated into these organic materials to form a metal-organic composite, enhancing the response by catalyzing and facilitating reactions. Upon exposure, gas vapors interact with the working materials, altering the fabric's electrical conductivity, which can be translated into signals to detect the presence of harmful gas vapors and provide information on their identities and concentrations. The formulation of sensors will be optimized for stability, signal sensitivity, response time, selectivity, and reusability. So far, we have demonstrated effective individual gas detection for the target analytes (ammonia, ethanol, octane, and acetic acid) using semiconductive composite sensing materials such as graphene oxide derivatives combined with Sn and Sn-In nanoparticles. Surfactant-assisted reduction methods are used to synthesize Sn/In nanoparticles. Studies incorporating these low-melting nano-solders into the nanocomposite will test their enhancement of mechanical properties and gas-sensing responses alongside traditional chemical crosslinking methods. Additional studies using Sn/In nanoparticles to join multiple sensors for simultaneous gas detection will also be conducted to examine their effectiveness as soldering materials. The soldered composite's electrical resistance, morphology, and elemental composition will be analyzed to verify bonding success, which is measured using a source meter, SEM, EDS, and FTIR. Lastly, the fabric sensors could be integrated into circuitry with an LED light or other types of visual or audio signals to display the gas response, which could be incorporated into the clothing of civilian or combat users, providing a real-time warning of hazardous gas vapors in their surroundings for personal protection.