2025 AIChE Annual Meeting

(169a) Dynamic Modeling of a Biogas Steam Reforming Plant

Authors

In Germany, around 6 % of the electricity production is based on biogas combined heat and power plants in 2023 [3]. Due to expiring subsidies, various options are currently being investigated to maintain economic operation and further expand the potential of biogas plants [4]. In addition to the electricity market, there is also the possibility of participating in the biomethane or green hydrogen market.

Producing green hydrogen from biogas is an interesting alternative alongside slowly ramping up water electrolysis projects. The decentralized location of biogas plants is advantageous for hydrogen supply to regional consumers, e.g., in the transport sector. Therefore, the project BioH2Log, funded by the German Federal Ministry for Economic Affairs and Climate Action, aims to develop and evaluate digital twins of hydrogen production, storage, and logistics for the demand-oriented and cost-effective production and distribution of green hydrogen to regional customers.

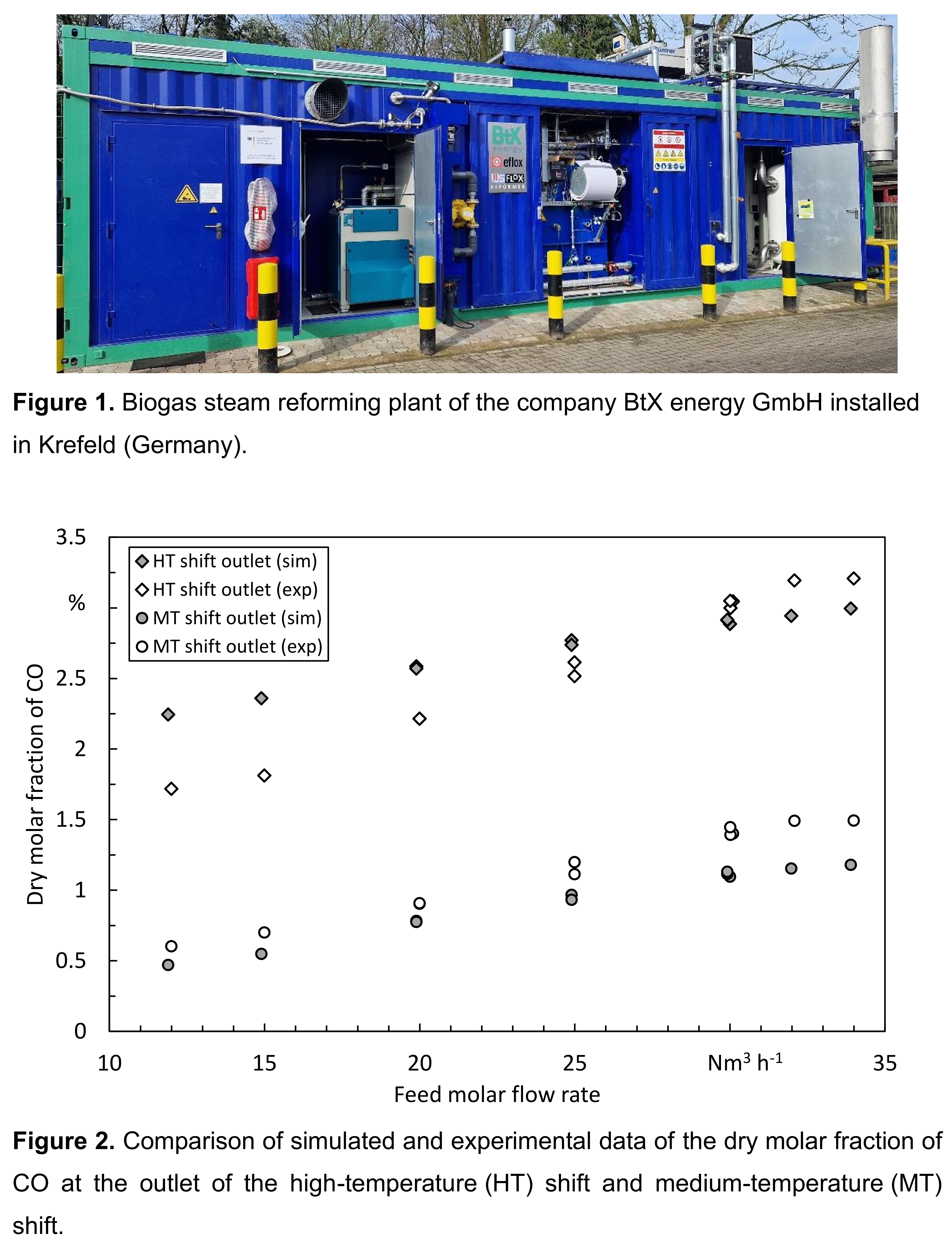

Towards modeling entire regions with several hydrogen-producing biogas plants and a multitude of consumers, we first develop a dynamic model of a single biogas steam reforming plant. Process data of a pilot biogas steam reforming plant, depicted in Fig. 1, is provided by our partner project BioH2Ref. This study focuses on developing a dynamic process simulation of the entire biogas steam reforming plant, which is implemented in Honeywell UniSim® Design. This process simulation comprises all relevant equipment of the pilot plant.

Various step tests were carried out at the pilot plant to validate this dynamic process simulation. The varied parameters include steam-to-carbon ratio, load, reformer temperature, and pressure. The results of the process simulation show a promising degree of correlation with the plant data, as depicted in Fig. 2. Eventually, our model can be used as a reliable tool for predicting operating points at different plant states, which can be utilized, e.g., to optimize operating procedures. The novelty of the study lies in the process itself, which directly converts biogas to hydrogen, and the immediate validation of our dynamic process model with steady-state and dynamic experimental data of a commercial-scale biogas steam reforming plant, which recently completed its pilot phase operation.

References

[1] IEA, Outlook for Biogas and Biomethane: Prospects for Organic Growth, IEA, Paris 2020.

[2] S. Jain, D. Newman, A. Nizhou, H. Dekker, P. Le Feuvre, H. Richter, F. Gobe, C. Morton, R. Thompson, Global Potential of Biogas, World Biogas Association, London 2019.

[3] DESTATIS, Stromerzeugung 2023: 56 % Aus Erneuerbaren Energieträgern - Pressemitteilung Nr. 087, DESTATIS 2024.

[4] J. Daniel-Gromke, N. Rensberg, V. Denysenko, T. Barchmann, K. Oehmichen, M. Beil, W. Beyrich, B. Krautkremer, M. Trommler, J. Vollprecht, et al., Optionen für Biogas-Bestandsanlagen bis 2030 aus ökonomischer und energiewirtschaftlicher Sicht, Umweltbundesamt, Dessau-Roßlau 2020.