2025 AIChE Annual Meeting

(139g) Discovery of an Unclarified Lignin Condensation Mechanism for Sustainable Aromatics Production from Camellia Oleifera Oil Shell Biomass

Authors

1. Introduction:

The studied Camellia oleifera shell (COS) biomass is collected from a tea oil mill. It composed of approximately 12% cellulose, 31% hemicellulose, and 34% lignin (Klason). The efficient utilization of each of those building block components is essential to maximize the value of the natural resource while minimizing the wastes. However, there are many side-reactions occurring during the biomass conversion processes. The lignin residues in pretreated biosolids can interfere with enzymatic hydrolysis, limiting the productivity of fermentable carbohydrates.1 The damage to lignin integrity during pretreatment impacts the value and yields of aromatic products in depolymerization.2 As interest grows in producing high-value lignin monomers, various biorefinery strategies have been developed to enhance lignin productivity and yields.3

Pretreatment using organosolv methods, such as alcohols, diols, and tetrahydrofuran (THF), has demonstrated advantages in lignin valorization. These processes often apply with diluted acids to cleave the ether linkages between hemicelluloses and lignin, with organosolv acting as a solvent for dissociated lignin from the biomass. However, too high pretreatment severity can lead to lignin condensation, which negatively impacts the production of both fermentable carbohydrates and monolignols. Despite significant efforts to mitigate lignin condensation through novel lignin dissociation chemistry, few studies have quantitatively assessed the relationship between delignification efficiency and monolignol yield from a process control perspective.

This study explores the kinetics of key building-block chemicals in lignocellulosic biomass within a lignin-first biorefinery. Lab-scale fractionation and depolymerization experiments were designed to convert cellulose, hemicellulose, and lignin in COS. A series of experiments were conducted, with the reaction products analyzed using advanced techniques. Lignin depolymerization mechanisms were studied, and new lignin condensation pathway were proposed, offering deeper insights into establishing a biorefinery process for the treatment of food and beverage waste.

2. Experiments

The COS was dried, milled, and sieved to obtain a powder with a maximum particle size of 150

μm. The biomass powder underwent Soxhlet extraction to remove polar and non-polar extractives. The extractive-free COS powder was then subjected to pretreatment using 1,4-butanediol (1,4-BDO) and different acidic catalysts: hydrochloric acid (HCl), ferric chloride (FeCl₃), and p-toluene sulfonic acid (p-TsOH). The pretreatment experiments involved varying the solid-to-solvent ratios, acid doses, and reaction temperatures and times.

Two groups of pretreatment methods were employed: single-batch and sequencing batch. In the single-batch process, biomass was treated with organosolv and acid catalyst at 121°C for 6 hours. The sequencing batch process involved multiple sub-batches with shorter reaction times, ensuring equivalent total solvent volume to the single-batch process.

After pretreatment, native COS lignin samples were prepared to gather structural information before pretreatment. The lignin-rich solution was processed for lignin precipitation and further analysis. Catalytic transfer hydrogenolysis (CTH) experiments were conducted for lignin depolymerization, using a Ru/C catalyst and THF solvent. Changes in lignin structures were determined using 2D-HSQC NMR, 31P NMR, and elemental analysis (EA).

3. Results and Discussion

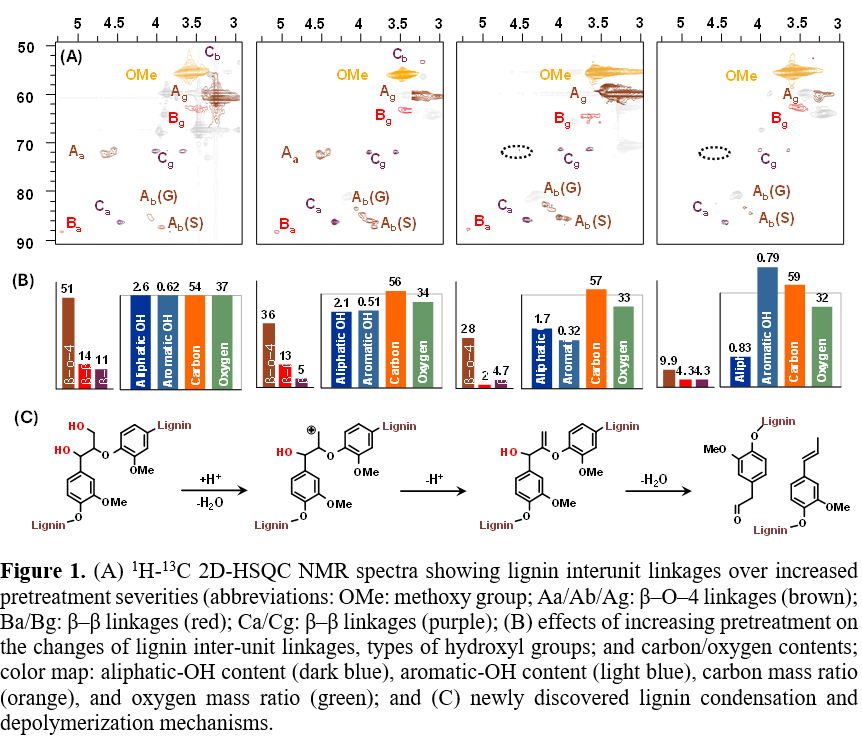

The results revealed dynamic changes in lignin inter-unit linkages with increasing pretreatment severities (from left to right, Fig.1). The fractionated lignin of COS at different pretreatment severities was characterized using 2D 13C-1H HSQC NMR, revealing variations in lignin inter-unit linkages (Fig.1A). The native COS lignin contained 50.7% β–O–4 ether linkages, with β–5 and β–β linkages also present. As pretreatment severity increased, the β–O–4 linkage percentage decreased, while β–β and β–5 linkages remained stable. The relationship between β–O–4 content and pretreatment severity was quantified, showing that delignification efficiency increased with severity, but β–O–4 linkages decreased due to lignin condensation (Fig.1B). Meanwhile, the S/G ratios of lignin subunits were lower than 1.0 at low pretreatment severities, indicating that S-lignin units are more difficult to remove than G-lignin. This finding suggests that G-lignin, with its vacant C5 position, is more prone to condensation, leading to a low S/G ratio at low severities. This information is valuable for optimizing pretreatment time and mitigating condensation reactions.

Analysis of lignin polarity changes during pretreatment revealed that the polarity of dissociated lignin could change at high severities due to hydroxyl group loss, leading to lignin precipitation and decreased delignification efficiency. 31P-NMR analysis quantified changes in lignin hydroxyl groups, and CTH experiments provided information on lignin aliphatic side chains and monolignol yields. The yield of G-type monolignols showed a more significant reduction than S-type monolignols with increasing pretreatment severity. Unexpected increases in certain monolignols were observed, suggesting dehydration or oxidation during pretreatment.

A new reaction route for lignin condensation was proposed, involving dehydration at the γ-OH position which led to side-chain cleavage and formation of short-chain lignin monomers (Fig.1C). This mechanism may explain the loss of hydroxyl groups in aromatic monomers found in depolymerization products. In the typical lignin condensation model, lignin condensation in acid-organosolv systems is initiated by proton attack at the Cα position, forming reactive benzylic carbocation intermediates that promote electrophilic coupling with other monolignol rings. In our study, however, despite high pretreatment severity, no increase in molecular weight of lignin fragments was observed, suggesting that lignin re-precipitation is not due to particle growth. Additional experiments using ethanol pretreatment and elemental analysis supported the hypothesis of lignin condensation mechanisms involving dehydration at the γ-OH position. More details of our findings will be presented in the AIChE2025 conference.

References

(1) Chan, K. L.; Ko, C. H.; Chang, K. L.; Leu, S. Y. Construction of a structural enzyme adsorption/kinetics model to elucidate additives associated lignin–cellulase interactions in complex bioconversion system. Biotechnology and Bioengineering 2021, 118 (10), 4065-4075.

(2) Dong, C.; Meng, X.; Yeung, C. S.; Ho-Yin, T.; Ragauskas, A. J.; Leu, S.-Y. Diol pretreatment to fractionate a reactive lignin in lignocellulosic biomass biorefineries. Green Chemistry 2019, 21 (10), 2788-2800.

(3) Khan, R. J.; Lau, C. Y.; Guan, J.; Lam, C. H.; Zhao, J.; Ji, Y.; Wang, H.; Xu, J.; Lee, D.-J.; Leu, S.-Y. Recent advances of lignin valorization techniques toward sustainable aromatics and potential benchmarks to fossil refinery products. Bioresource Technology 2022, 346, 126419.