2025 AIChE Annual Meeting

(417c) Direct Air Capture By Aqueous Amine Solvent and Electrochemical Reduction to Carbon Monoxide

Authors

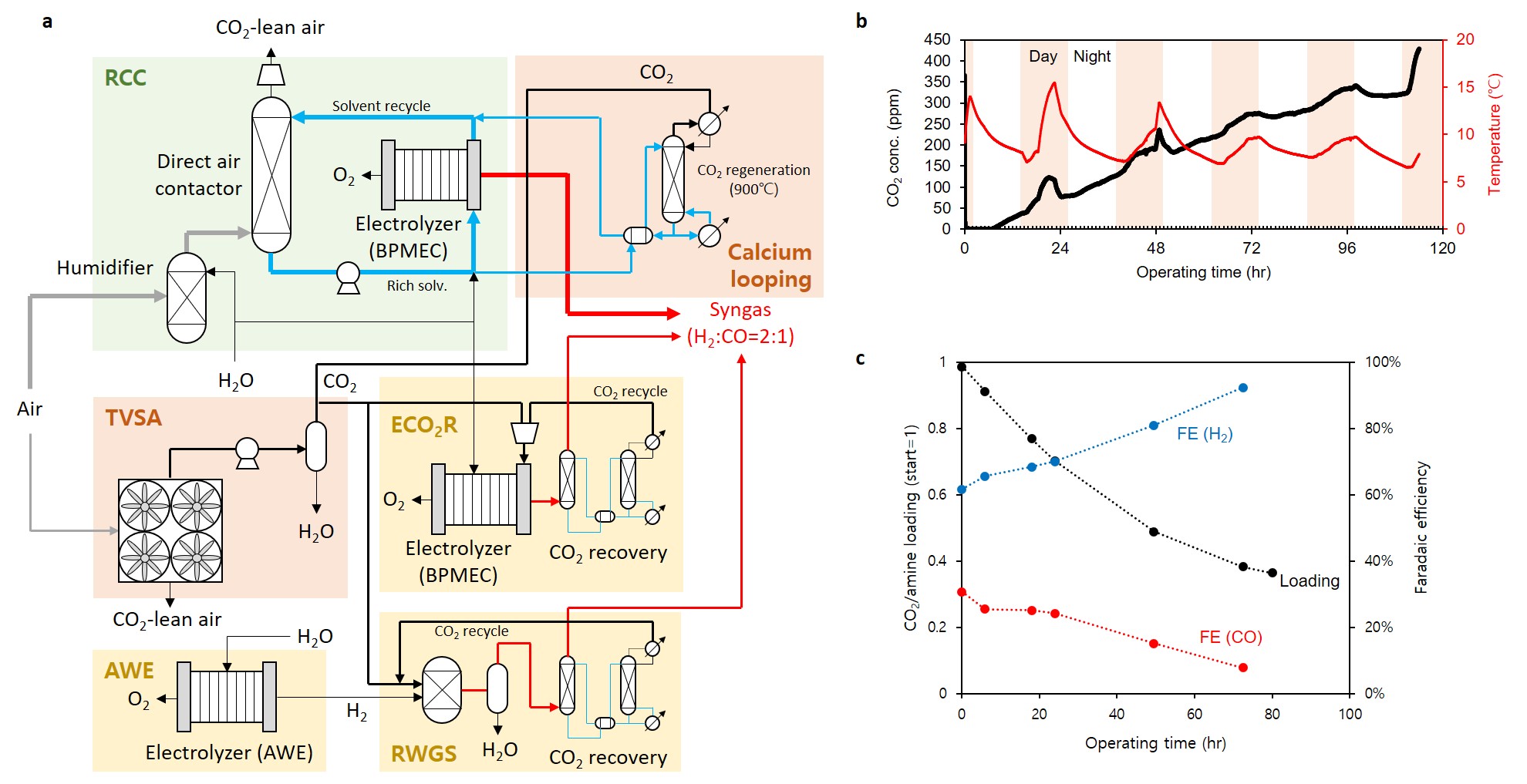

Herein, we propose a noble DACU process that combines amine scrubbing and electrochemical CO2 reduction to CO. The main strategy is reactive carbon capture (RCC) which uses rich solvent as catholyte to generate CO.3,4 CO2 regeneration in TVSA/calcium looping and CO2 recovery in the CO2 utilization section can be avoided by RCC (Fig. 1a). When mixed with green hydrogen, syngas with an H2:CO ratio of 2:1 can be supplied to produce methanol, ethylene, and other products. First, we tested amine scrubbing of air by aqueous amine solvent in a pilot column to examine performance of structed packing as a direct air contactor (Fig. 1b). Then, we tested the electrochemical CO2 reduction of CO2-rich solvent in a membrane electrode assembly using Ag-Ag/C cathode (Fig. 1c). Based on the experimental results and assumptions, techno-economic assessment and life cycle assessment is conducted. Other DACU routes are also evaluated to access the competitiveness of our process. The results show that DACU by RCC outperforms other routes in terms of energy consumption, cost, and indirect greenhouse gas emissions.

Figure 1. Direct air capture and utilization (DACU) by reactive carbon capture (RCC). (a) Comparison between RCC and other DACU routes to generate syngas. (b) Pilot test results of CO2 capture using aqueous amine solvent. (c) Test results of electrochemical CO2 reduction.

References

[1] Deutz and Bardow, Life-cycle assessment of an industrial direct air capture process based on temperature–vacuum swing adsorption, Nature Energy 6, 203-213, 2021.

[2] Keith et al., A process for capturing CO2 from the atmosphere, Joule 2, 1573-1594, 2018.

[3] Langie et al., Toward economical application of carbon capture and utilization technology with near-zero carbon emission, Nature Commun. 13:7482, 2022.

[4] Song et al., Integrated carbon capture and CO production from bicarbonates through bipolar membrane electrolysis, Energy Environ. Sci. 17, 3570, 2024.