2025 AIChE Annual Meeting

(53g) Development of an Onboard IPA-SCR System Using Agco/Al2O3 Catalyst for Enhanced Denox Performance in Semiconductor FAB Emission Control

Authors

Ag/Al2O3 are known for high deNOx activity and N2 selectivity in OHC-SCR reactions. However, under low-humidity conditions (<3% H2O), commonly encountered in fuel-free FAB environments, the catalytic activity of Ag/Al2O3 is significantly inhibited. Therefore, to effectively utilize IPA for NOx abatement in such dry conditions, it is essential to develop a novel catalyst that can maintain high deNOx activity without water vapor.

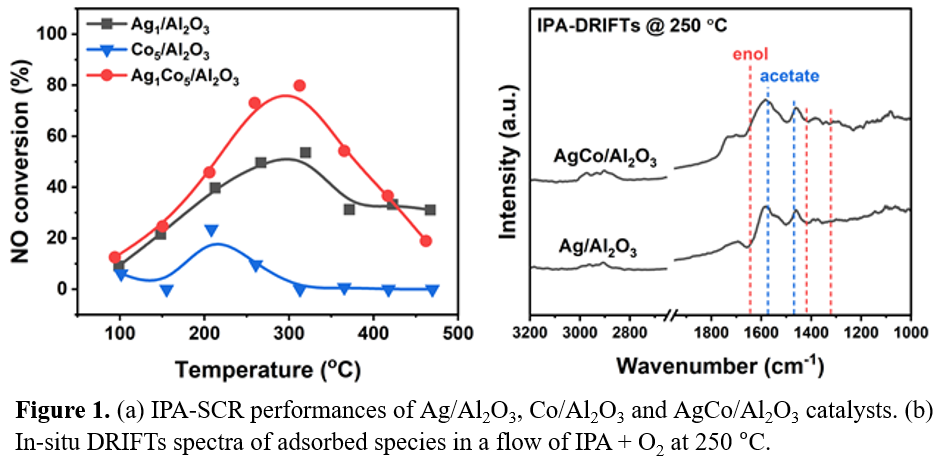

Herein, we report a highly active AgCo/Al2O3 for IPA-SCR that exhibits excellent performance under low H2O conditions. As shown in Figure 1a, the AgCo/Al2O3 achieves approximately 80% NOx conversion, significantly outperforming conventional Ag/Al2O3. This enhancement is attributed to the formation of Co3O4, promoted by co-impregnation of Ag and Co. In-situ DRIFTs provide the most significant insight: Co3O4 species facilitate activation of IPA into highly reactive enol intermediates (Figure 1b), which subsequently leads to the formation of abundant -NCO and -CN species. This enhanced formation of reactive intermediates leads to improved NOx conversion. These findings underscore the practical applicability of AgCo/Al2O3 for FAB operations, particularly in dry environments with low moisture in the exhaust. We will provide more detailed insights into the contributions of Ag and Co in the IPA-SCR at the upcoming AIChE meeting.