2025 AIChE Annual Meeting

(673c) Development of a Digital Platform for the Optimised Production of Sustainable Biopolymer Products

Only 9% of all plastics ever produced have been actively recycled, while the remaining 91% either end up in landfills or are downcycled into lower quality products [1]. With global plastic waste generation reaching 400 million tonnes annually [2], a fundamental shift in material usage is essential.

Ultimately, a products end of life is determined by the materials from which it is formulated, and how it is processed. Aquapak Polymers LTD has developed a flagship product- HydroPol; a novel biopolymer derived from Poly-Vinyl Alcohol (PVA) with plant-based additives. HydroPol matches or surpasses conventional plastics in performance while eliminating the adverse environmental impact. This innovation enables the production of sustainable alternatives for food packaging, laundry bags, paper coatings, non-woven fibres like dental floss and even injection-moulded items such as COVID-19 test kits and bottles [3]. Notably, HydroPol dissolves in warm water, ensuring no toxic residue enters water systems, further reinforcing its eco-friendly benefits [3]. The manufacture of HydroPol employs twin screw extrusion technology, which involves a thermal and mechanical manipulation of PVA and additives.

Twin-screw extruders, as depicted in figure 1, are “black box” systems, while the inputs and outputs are known, the internal process dynamics remain poorly understood. Additionally, PVA has a narrow thermal processing window, making it susceptible to degradation. To optimize HydroPol production and deepen the understanding of twin-screw extrusion, Aquapak is collaborating with the University of Birmingham to develop a digital platform for the optimised production of Hydropol. This entails the use of advanced methodology for the generation of novel twin screw geometries, highly calibrated numerical modelling techniques to understand the complex physics and dynamics to of twin screw systems. From this evolutionary AI can be applied to the system to optimise the screw geometry, arrangement and operating conditions, thereby enhancing efficiency, reducing waste, and refining the manufacturing process, ensuring HydroPol can serve as a viable, scalable solution to the global plastic crisis [3].

METHOD

Methodology of Twin screw geometry generation

The screws in the extruders are a key component of the system, as they interact with the materials- dictating the shear magnitude and residence time profile of a given quantity of material. Hence, a key component for optimisation. Evolutionary algorithms require the presentation of the geometrical properties of a system as scalar parameters, such that the values of the free parameters can be varied to develop novel designs. This is not achievable through classical CAD software such as a Fusion 360, SolidWorks etc. Therefore, Gmsh; a 3D parametric mesh generator which can be imported into python scripts has been employed, such that every single geometric property that dictates the 3D model of the screws is mathematically defined. From this, by changing a value of any of the geometric properties, accounting for the physics occurring around a give screw element, novel and innovative designs can be achieved at an accelerated rate. See results section for the capabilities of Gmsh.

RESULTS

Mathematical description and generation of twin screw extruder geometries

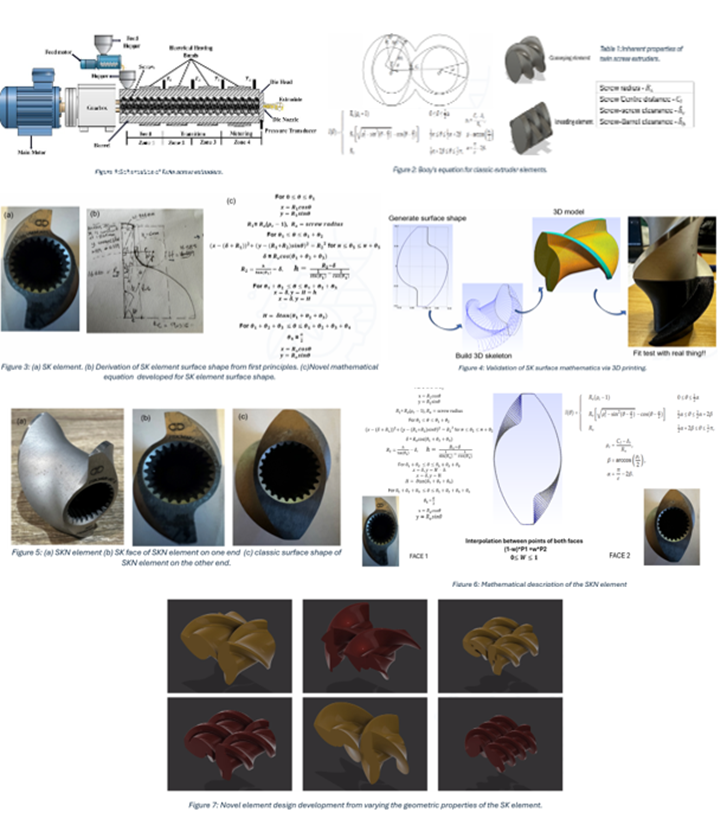

For classic surface shape of intermeshing twin screw extruder geometries, for both kneading and conveying elements, the well-established Booy’s equation applies, see figure 2. It describes the surface shape mathematics by accounting for the inherent properties of the twin screw system stated in table 1 below

However, complex elements do exist such as the SK element (see figure 3), which is used for powder flow and the SKN element, which is a transitional element between the SK element and the classic conveying element shown in figure 2. It consists of two faces, one face is purely the surface shape of the SK element, and it slowly morphs across its length into the classic conveying element shape, see figure 5.

From first principles in figure 3b, the surface shape of the SK element has been carefully analysed from which, a complete set of mathematical equations that describe the surface shape of the SK element has been derived as in figure 3c. To check that the equations in figure 3c are valid and accurate, a 3D model of the SK element was generated in Gmsh and 3D printed and tested against a real SK element as in figure 4.

With the SK element mathematics developed and validated, the complexity of the SKN element can be dealt with by describing an interpolation parameter w, which has values between 0 and 1, such that when w = 0, the surface shape is fully the SK element surface and when w = 1, its surface is fully the classic extruder surface described by Booy’s equations.

Using the SK element as a case study, by changing any of its geometrical properties, we can start to uncover novel design applicable to twin screw extruders, as shown in figure 7, the original SK element design is the top-left.

By incorporating object-oriented programming and a function-based approach, an entire screw configuration can be generated in Gmsh in minutes. Figure 8 showcases a 2.5 m long industrial scale twin screw extruder configuration generated in Gmsh via python. This method is scalable, dynamic and rapid when generating any screw configuration. By coupling the geometry generation method with evolutionary AI, we can start to uncover innovative design and improve the performance of twin screw extruders to facilitate high productivity of sustainable biopolymer products, towards a greener economy.

References

[1] Ncube, L. et al., 2021. An Overview of Plastic Waste Generation and Management in Food Packaging Industries. Recycling, 6(12)

[2] Mazhandu, Z. & Muzenda, E., 2019. Global Plastic Waste Pollution Challenges and Management. Agadir, Institute of Electrical and Electronics Engineers Inc..

[3] Aquapak Polymers LTD, 2024. AQUAPAK. [Online]

Available at: https://www.aquapakpolymers.com/markets-applications/

[Accessed 13 January 2025].