2025 AIChE Annual Meeting

(501e) Designing the Optimal Adiabatic Indirect Cooled Reactor System for Renewable Ammonia Production

The core part of every HB plant is the reactor system, which usually comprises several heat-integrated reactor beds. Several reactor types are used in the industry; however, we focus on the adiabatic indirect cooled reactor (AICR) system, which is particularly favorable for renewable HB plants due to its stable operability under varying process conditions and ability to enable high hydrogen conversion rates [2]. The AICR reactor consists of two to four reactor beds, with stream inlet cooling provided by interbed heat exchangers and the feed-to-effluent heat exchanger. A sensitivity analysis reveals that the precise sizing of the adiabatic reactor beds has a significant influence on the single-path hydrogen conversion, ultimately leading to decreased equivalent annual operating costs (EAOC). Besides the bed sizes, the controlled bed inlet temperatures also significantly affect the conversion rate and need to be considered during the sizing of the reactor beds.

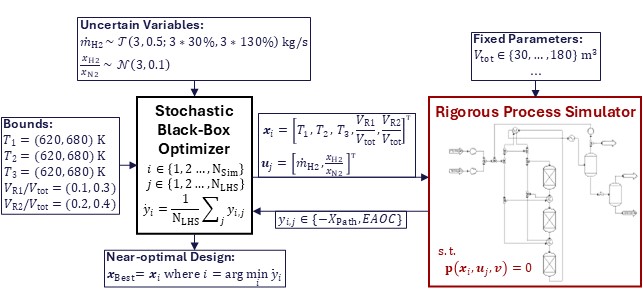

To achieve our goal of finding the optimal AICR design by maximizing its single-pass conversion or minimizing the EAOC, we connect the stochastic black-box optimizer MOSKopt [3] with an HB simulation model. The simulation model encompasses all process and product quality constraints, providing rigorous results. Before initiating the optimization procedure, initial design points are sampled from the specified bounds for the decision variables. For each design point, Monte Carlo simulations are performed by sampling the uncertain parameters from their respective distributions. The mean objective values of these simulations are then used to construct the surrogate model. Subsequently, the surrogate model is optimized to propose new design points, which are again evaluated using Monte Carlo simulations. The results from all simulations are used to update the surrogate model through iterative adaptive sampling. After a specified number of iterations, the design with the best mean objective value is selected.

This work provides a systematic basis for designing AICR systems, laying the groundwork for recent approaches in planning renewable ammonia plants coupled with green hydrogen production. The combination of sensitivity and uncertainty analysis with optimization enables process designers to make data-driven decisions supported by rigorous process simulations, thereby increasing the efficiency of flexible, renewable ammonia production plants.

[1] C. Smith, A. K. Hill, and L. Torrente-Murciano, “Current and future role of Haber–Bosch ammonia in a carbon-free energy landscape,” Energy & Environmental Science, vol. 13, no. 2, pp. 331–344, Feb. 2020, doi: 10.1039/C9EE02873K.

[2] J. W. Rosbo, A. D. Jensen, J. B. Jørgensen, and J. K. Huusom, “Comparison, operation and cooling design of three general reactor types for Power-to-Ammonia processes,” Chemical Engineering Journal, vol. 496, p. 153660, Sep. 2024, doi: 10.1016/j.cej.2024.153660.

[3] R. Al, C. R. Behera, K. v. Gernaey, and G. Sin, “Stochastic simulation-based superstructure optimization framework for process synthesis and design under uncertainty,” Computers & Chemical Engineering, vol. 143, p. 107118, Dec. 2020, doi: 10.1016/j.compchemeng.2020.107118.