2025 AIChE Annual Meeting

(584at) Design and Heat Transfer Modeling of Dynamic Microreactor for Millisecond Temperature Pulses

Authors

Felipe de Faria Teixeira - Presenter, Worcester Polytechnic Institute

Cameron Armstrong, Worcester Polytechnic Institute

Fatou Baka Diop, Worcester Polytechnic Institute

Andrew Teixeira, Worcester Polytechnic Institute

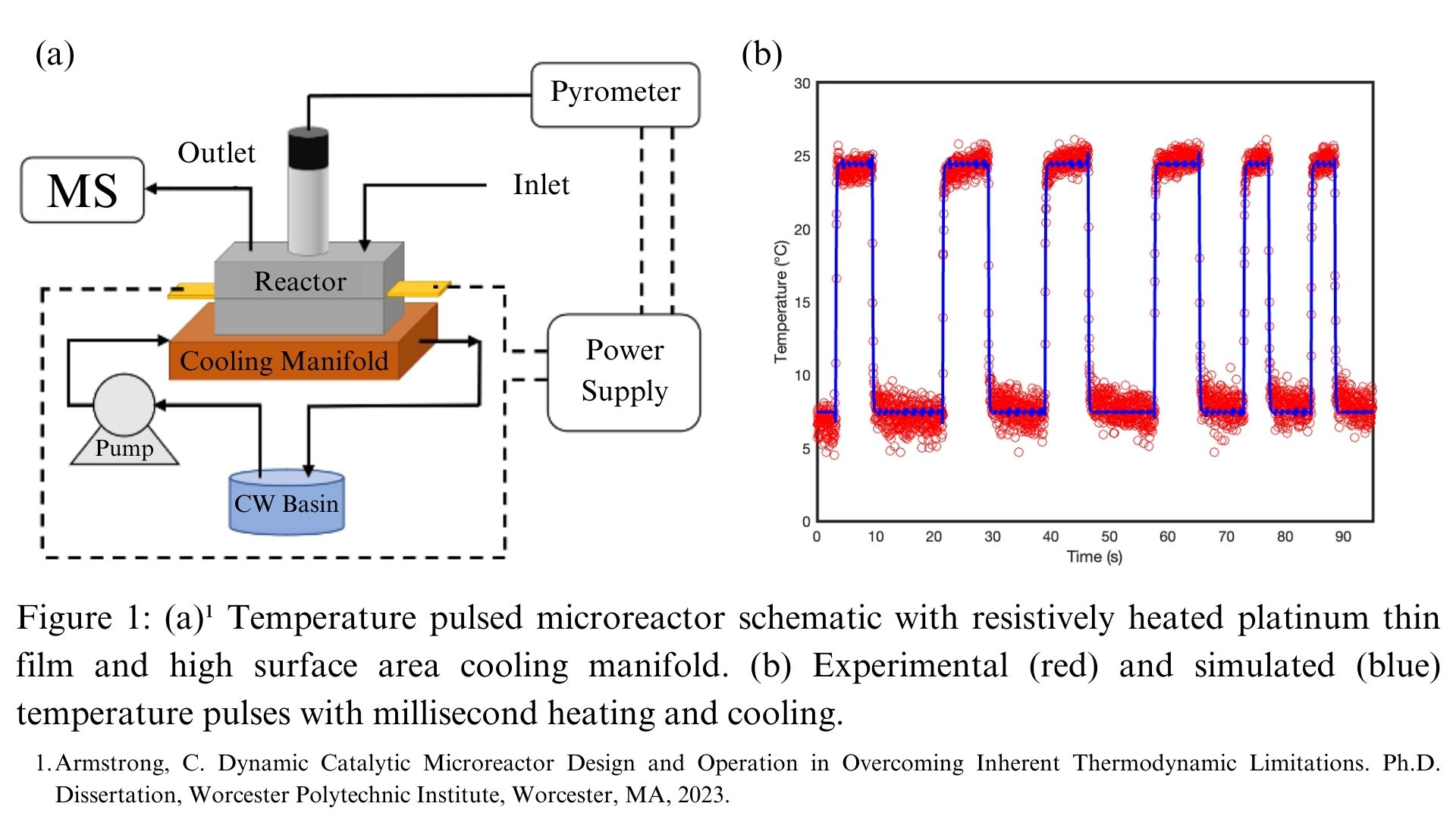

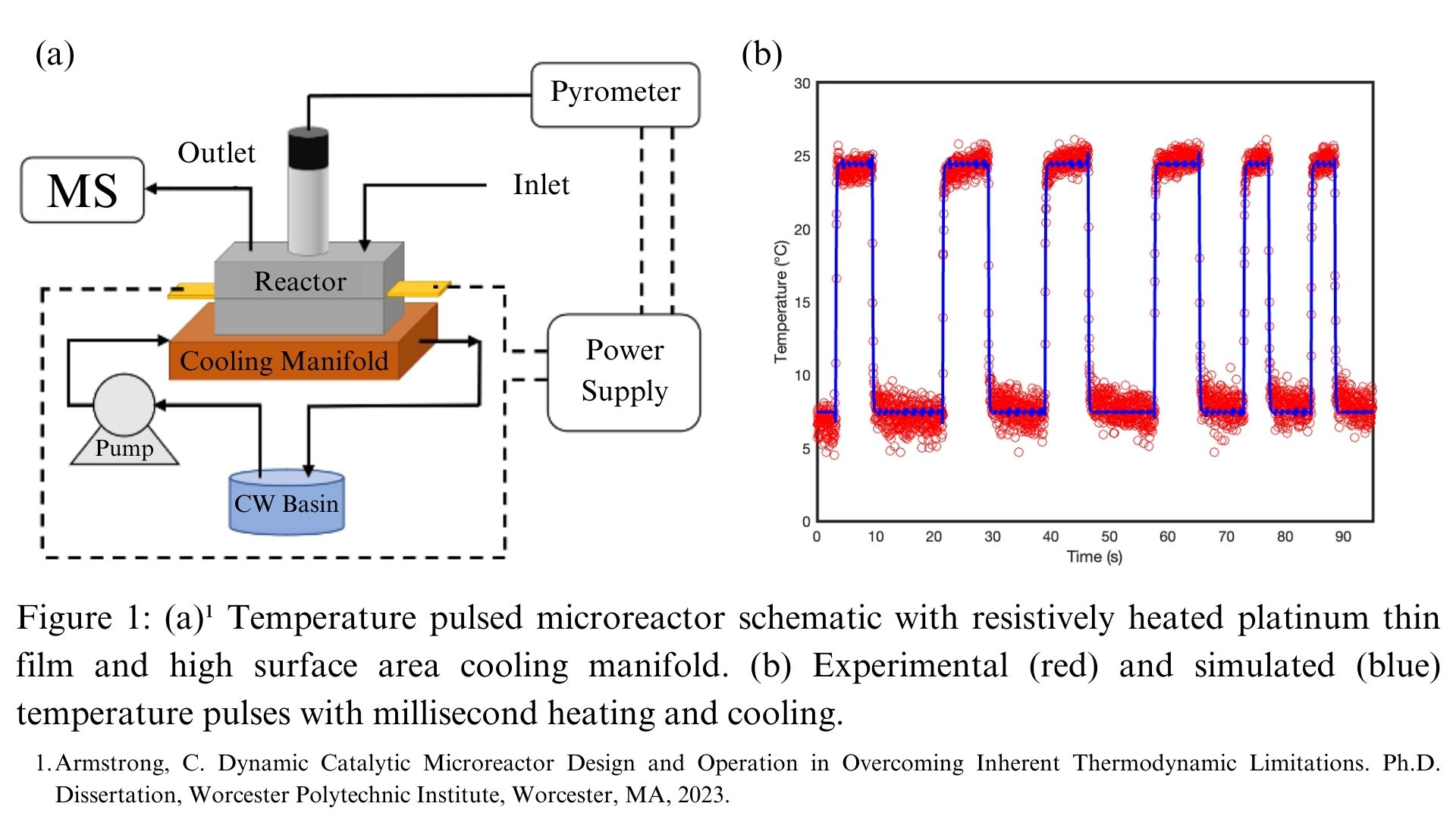

Shifting from centralized to distributed chemical manufacturing (DCheM) has driven innovation in microreactor technology to enable localized, small-scale chemical processing in geographically-remote locations lacking transportation infrastructure. The competitiveness of DCheM systems requires reactor performance beyond thermodynamic limits. Such operation windows are unlocked by short transport lengths in microreactors, enabling innovative modes of operation like dynamic catalysis that can enhance reactor performance through the modulation of process inputs like temperature or pressure, instead of traditional static operation. Modulating catalyst temperature to optimize adsorption at low temperature and reaction at high temperature has shown to enhance catalytic turnover, attributed to distinct phenomena: tuning of surface coverage for optimal energetics, operation in favorable thermodynamic conditions, or periodic surface cleaning. Investigating the effects of dynamic operation on competing elementary steps requires distinct temperature oscillation at frequencies comparable to catalytic turnover (0.1 - 100 Hz). Our previous reactor design, a resistively-heated platinum wire, achieved sharp square waves at a pulsing frequency of up to 2 Hz and peak conversion at 10 Hz for carbon monoxide oxidation, where slow heating/cooling set a limit for distinct pulses at high frequency. In this work, we designed and modeled a differential chip microreactor with a high surface area cooling manifold and oscillating joule heating of a platinum thin film catalyst, supported on an aluminum nitride chip (fig.1). A pyrometer is used for fast temperature measurement. A lumped-capacitance heat transfer model was developed to estimate the optimal platinum thickness for millisecond heating and cooling. The overall heat transfer coefficient was fitted from experimental heating/cooling pulses to predict the maximum frequency for sharp square waves. With a power input of 60 W, 0.3 Hz square waves of 20 K amplitude were obtained, and a limit of 6 Hz is predicted with a power of 3 kW, enabling higher frequency dynamic operation.