2025 AIChE Annual Meeting

(651c) Derivation and Scaling of Kinetic Models from Plastic Waste TGA Experiments for Chemical Recycling Reactor Design

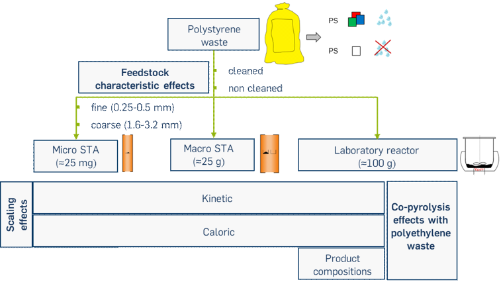

Due to their robustness, chemical recycling processes such as pyrolysis and liquefaction are currently being discussed as a promising solution to complement the mechanical recycling by being able to process, unsorted and impure plastic waste fractions. One of the main challenges of the development of these processes is the scale-up which is due to a lack of knowledge of the – typically very complex – reaction system and the mechanisms within the reactor, while varying and inhomogeneous waste compositions and impurities makes this challenge even more difficult. To better understand and describe the degradation behavior of “real world” plastic waste, research is needed to understand the influence of feedstock characteristics, as composition variations, impurities and particle size variations on the degradation kinetics, product generation and product composition. To investigate such effects, and to derive kinetic models allowing for the model-based design and scaling of chemical recycling reactors, this submission presents a kinetic study of the degradation of two plastic wastes from “real world” sorting, polystyrene (PS) and polyethylene (PE). Kinetic parameters are derived from simultaneous thermogravimetric analysis (STA) measurements and the influence of different degrees of feedstock contamination, particle size fractions and co-pyrolysis effects of simultaneous degradation of PE and PS are investigated. To examine the scale-up of these effects, the experiments were performed at three scales: Micro (25 µg) and Macro (25 g) STAs to generate kinetic parameters and laboratory reactor experiments to validate the kinetic triplets and respective effects. In our contribution, we discuss possible applications of such fundamental knowledge for reactor scaling and the role of µTGA measurement in future kinetics derivation studies for a knowledge-based chemical recycling reactor design.