2025 AIChE Annual Meeting

(196b) Deconvoluting the Effects of Diffusion and Compositional Gradients in Hierarchical MFI-Type Catalysts for the Methanol-to-Hydrocarbons Reaction

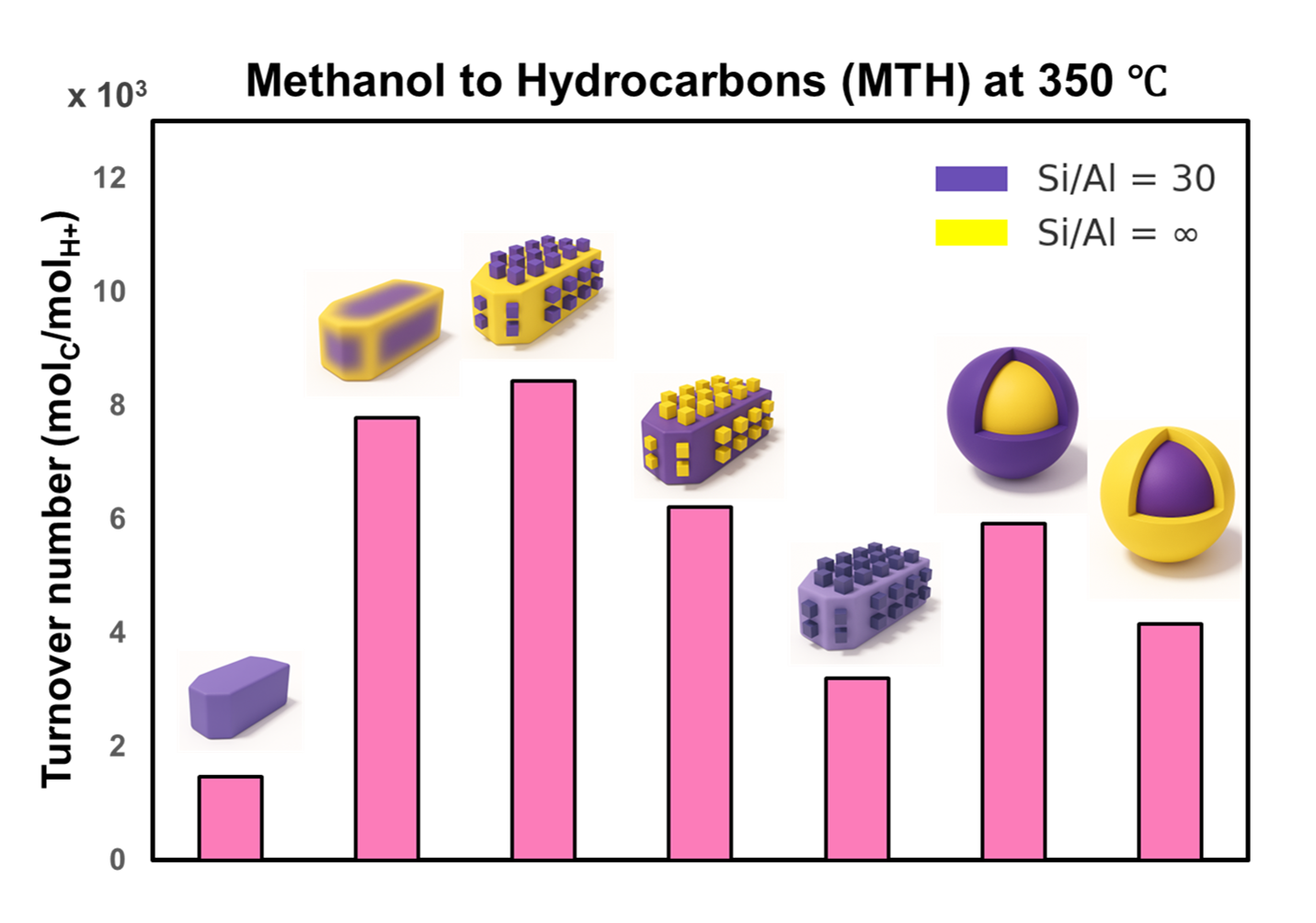

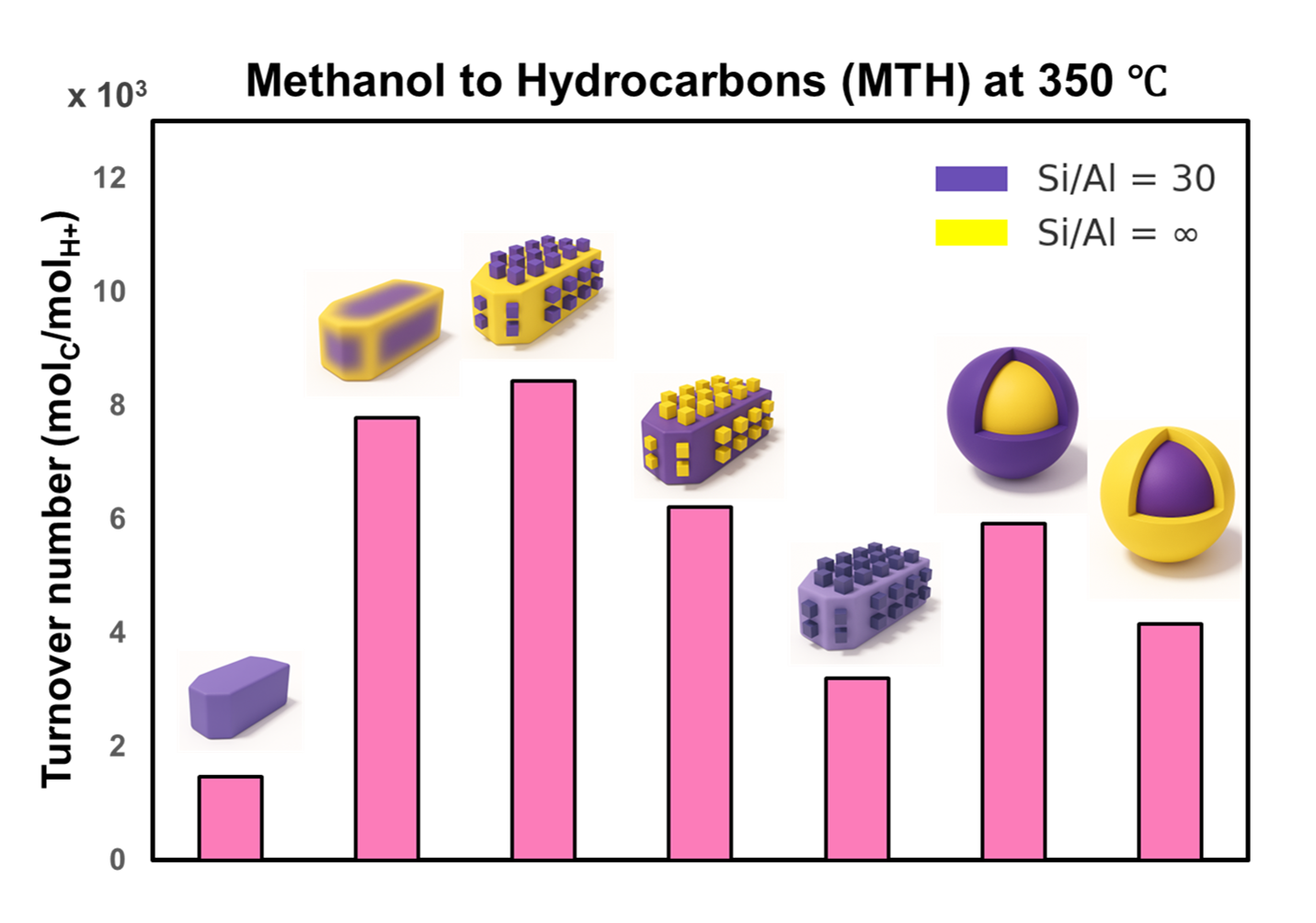

Post-synthesis modifications of zeolites offer efficient routes to tune their catalytic performance by engineering morphology and/or aluminum distribution. In this presentation, we will discuss the mechanisms of secondary growth – a method used to produce fins or core-shell structures. The impact of these processes on catalyst performance is assessed using the methanol to hydrocarbon (MTH) reaction. To deconvolute active sites in different regions of zeolite catalysts, we designed a series of zeolite MFI-type materials with gradients in Si/Al ratio and assessed their performance in MTH reactions as well as their diffusion properties. We demonstrated that finned and core-shell structures with Si-zoning (i.e., Si-rich exterior features) outperform conventional and commercial ZSM-5 with homogeneously distributed Al sites throughout the catalyst particle. These effects are attributed in part to surface passivation to mitigate external coking, but also a recently discovered enhancement of hydrocarbon diffusion through siliceous regions of MFI catalysts. We also prepared Al-zoned materials with catalytically inert cores (i.e., silicalite-1) and showed that these materials exhibit superior catalytic performance to those of Si-zoned materials. The Al-zoned function as pseudo nanoparticles (for finned zeolites) and nanosheets (for core-shells) to enhance Al active site accessibility. Our findings reveal that finned MFI zeolites are consistently better MTH catalysts than core-shell structures. We posit these differences are due in part to the introduction or removal of defects during secondary growth. Using a combination of catalytic data and diffusion studies, this study addresses a longstanding question regarding the role of active sites in these hierarchical zeolite catalysts, demonstrating that not only do fins significantly improve internal diffusion, but also provide the primary active sites for the reaction. Collectively, we will discuss a comprehensive framework for designing high-performance zeolite catalysts through post-synthetic methods that introduce elemental zoning, thus offering promising strategies for extending catalyst lifetime in industrial applications.