2025 AIChE Annual Meeting

(326g) Data Augmentation and Dynamic Time Warping Enabled Ensemble Modeling Framework for Bearing Remaining Useful Life Prediction

Authors

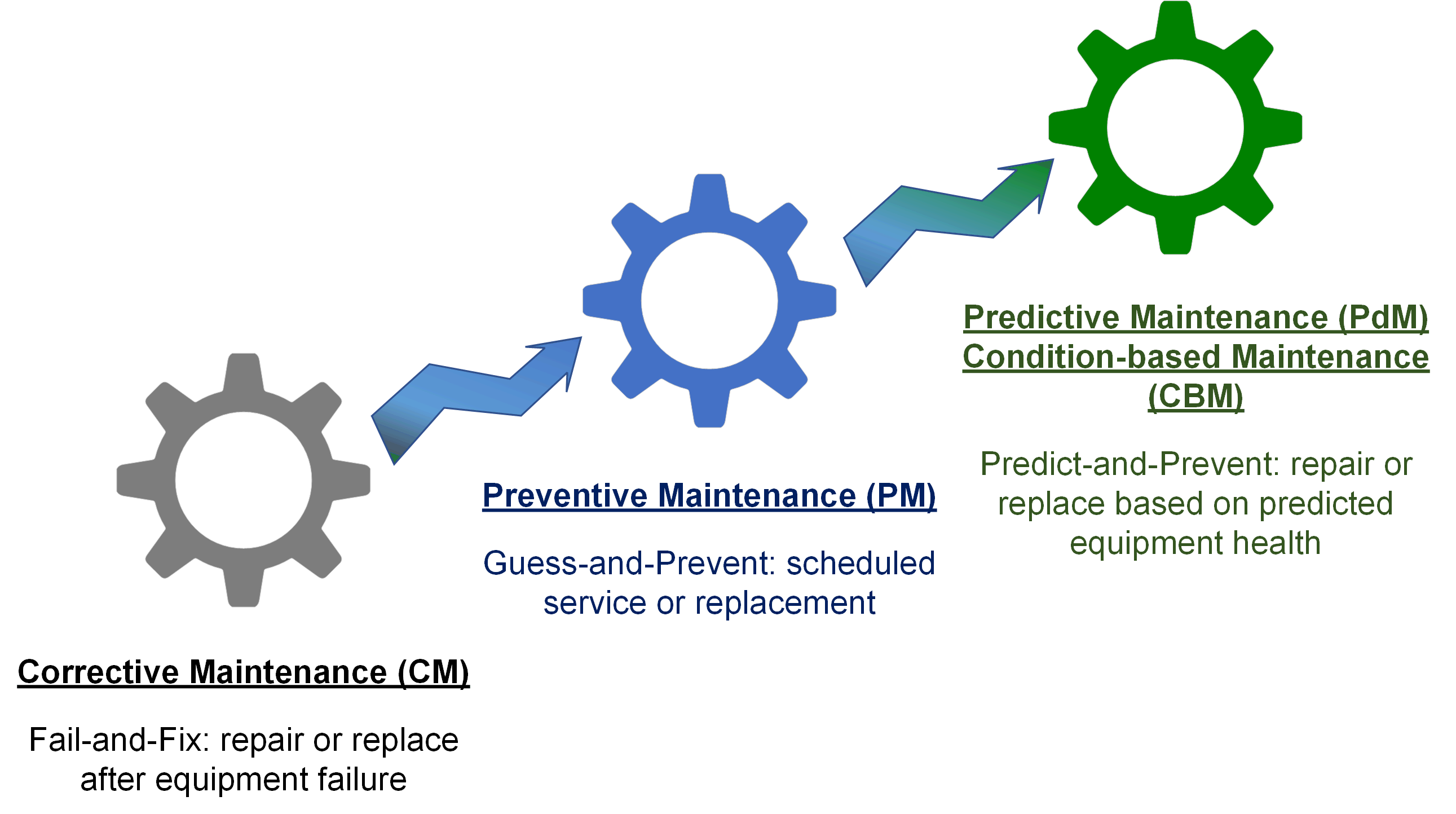

As shown in Fig. 1, the traditional equipment maintenance strategies have been corrective maintenance (CM, “fail-and-fix”) and preventive maintenance (PM, “guess-and-prevent”). Recently, a more efficient strategy, condition-based maintenance (CBM) or predictive maintenance (PdM, “predict-and-prevent”), has drawn increasing research interest, as it could reduce equipment downtime and minimize maintenance costs in comparison to CM and PM [1], [2]. CBM makes use of condition monitoring data to estimate the “health” status of the equipment or its parts, and then take maintenance action accordingly. Estimation of bearing RUL is the most critical component in enabling CBM of bearings and hence rotating machines as a whole.

The commonly used measurements in bearing RUL estimation include vibration, oil debris, and acoustic emission [3], [4]. In this work, we focus on vibration measurements, as they are easy to collect, widely available for various processes, and most commonly studied in the literature. RUL estimation techniques can be roughly classified into two categories: model-based and data-driven [4], [5]. The former attempts to describe the physics of a system and failure mechanisms through mechanistic models. If the physics of the system is well understood and the model explains failure mechanisms well, this approach could provide accurate RUL estimation. In practice, however, bearing failure mechanisms are often complex and stochastic, making capturing the underlying physical principles with a few mathematical equations very challenging. On the other hand, data-driven approaches apply statistical/machine learning or deep learning to historical data and estimate RUL from the data only. Without requiring the underlying mechanisms for different bearing failures, data-driven approaches have found more usage in estimating the RUL of bearings in real applications and are the focus of this work. However, there are many challenges for data-driven approaches as well, which include: (1) limited training data, (2) limited observations after degradation onset, (3) drastically different RULs among bearings, and (4) highly variable degradation progression due to highly complex and often stochastic bearing failure mechanisms. In this work, we proposed an extreme learning machine (ELM) based ensemble modeling framework to address these challenges. Specifically, a data augmentation approach is proposed to address challenge #1; an untuned single-hidden-layer ELM is utilized to address challenge #2; normalization of features and RULs are proposed to address challenge #3; dynamic time warping (DTW) and ELM, together with ensemble modeling, are proposed to address challenge #4.

The novelties of this work include: (1) for the first time, data augmentation (DA) has been investigated to address small sample size in the bearing RUL prediction field, as well as the class imbalance issue typically observed in bearing RUL prediction (i.e., there are much fewer bearings that follow less typical degradation trajectories in the training set); (2) for the first time, dynamic time warping (DTW) has been investigated for bearing RUL prediction and its effectiveness was demonstrated; (3) in order to evaluate the role of ELM in the proposed framework, we have conducted a systematic comparison of ELM to other simpler (e.g., exponential, polynomial, and spline), and more complex (e.g., neural network) nonlinear regression models in RUL prediction.

The benchmark PRONOSTIA dataset is used to assess the performance of the proposed framework and compare it to two deep neural nets (DNN) approaches [6], which are state-of-the-art for bearing RUL estimation. The results show that the proposed framework (both with and without DA) outperforms the DNN based methods significantly for the estimation of for all bearings using all performance metrics. Three different performance metrics were included: mean absolute error (MAE), root mean square error (RSME) and mean absolute percentage error (MAPE). For 10 out of 11 bearings, the proposed methods reduce , and in estimation by over 50%. In addition, the results confirm that DA is particularly effective in improving RUL estimation for bearings with atypical degradation trajectories that deviate from those of typical bearings. Although the proposed ensemble modeling framework was developed using vibration signals as model input, it can be extended to other features easily for RUL estimation.

References:

[1] B. Lu, D. B. Durocher, and P. Stemper, “Predictive maintenance techniques,” IEEE Industry Applications Magazine, vol. 15, no. 6, pp. 52–60, 2009.

[2] M. Paolanti, L. Romeo, A. Felicetti, A. Mancini, E. Frontoni, and J. Loncarski, “Machine learning approach for predictive maintenance in industry 4.0,” in 2018 14th IEEE/ASME International Conference on Mechatronic and Embedded Systems and Applications (MESA), IEEE, 2018, pp. 1–6.

[3] C. Malla and I. Panigrahi, “Review of Condition Monitoring of Rolling Element Bearing Using Vibration Analysis and Other Techniques,” Journal of Vibration Engineering & Technologies, pp. 1–8, 2019.

[4] J. Lee, F. Wu, W. Zhao, M. Ghaffari, L. Liao, and D. Siegel, “Prognostics and health management design for rotary machinery systems—Reviews, methodology and applications,” Mech Syst Signal Process, vol. 42, no. 1–2, pp. 314–334, 2014.

[5] A. Heng, S. Zhang, A. C. C. Tan, and J. Mathew, “Rotating machinery prognostics: State of the art, challenges and opportunities,” Mech Syst Signal Process, vol. 23, no. 3, pp. 724–739, 2009.

[6] X. Li, W. Zhang, and Q. Ding, “Deep learning-based remaining useful life estimation of bearings using multi-scale feature extraction,” Reliab Eng Syst Saf, vol. 182, pp. 208–218, 2019.