2025 AIChE Annual Meeting

(57a) Damköhler Numbers to Modulate Neat and Catalytic Polyolefin Pyrolysis

Authors

Hsi-Wu Wong - Presenter, University of Massachusetts Lowell

Mihriye Doga Tekbas, University of Massachusetts-Lowell

Matthew Wright, University of Massachusetts Lowell

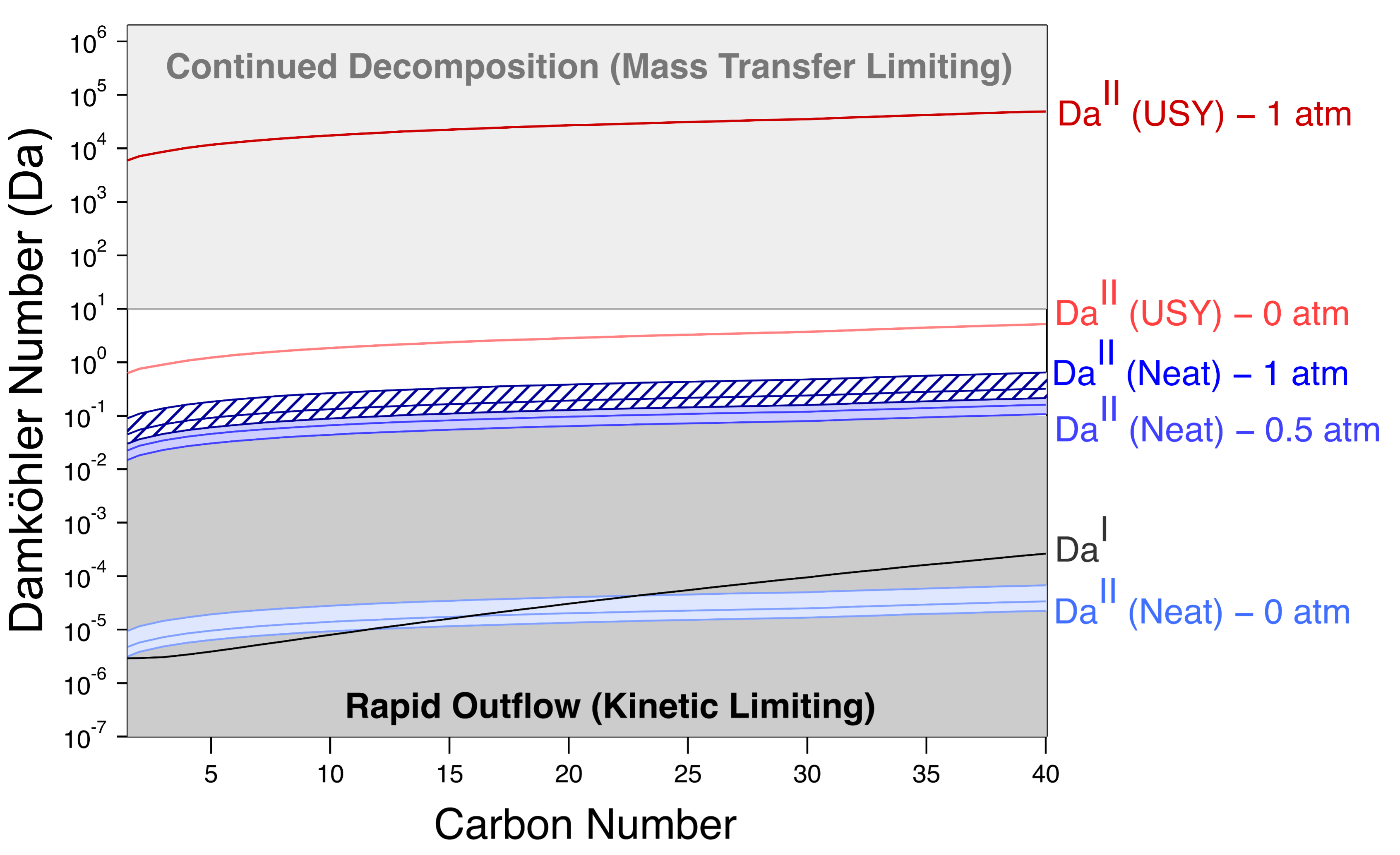

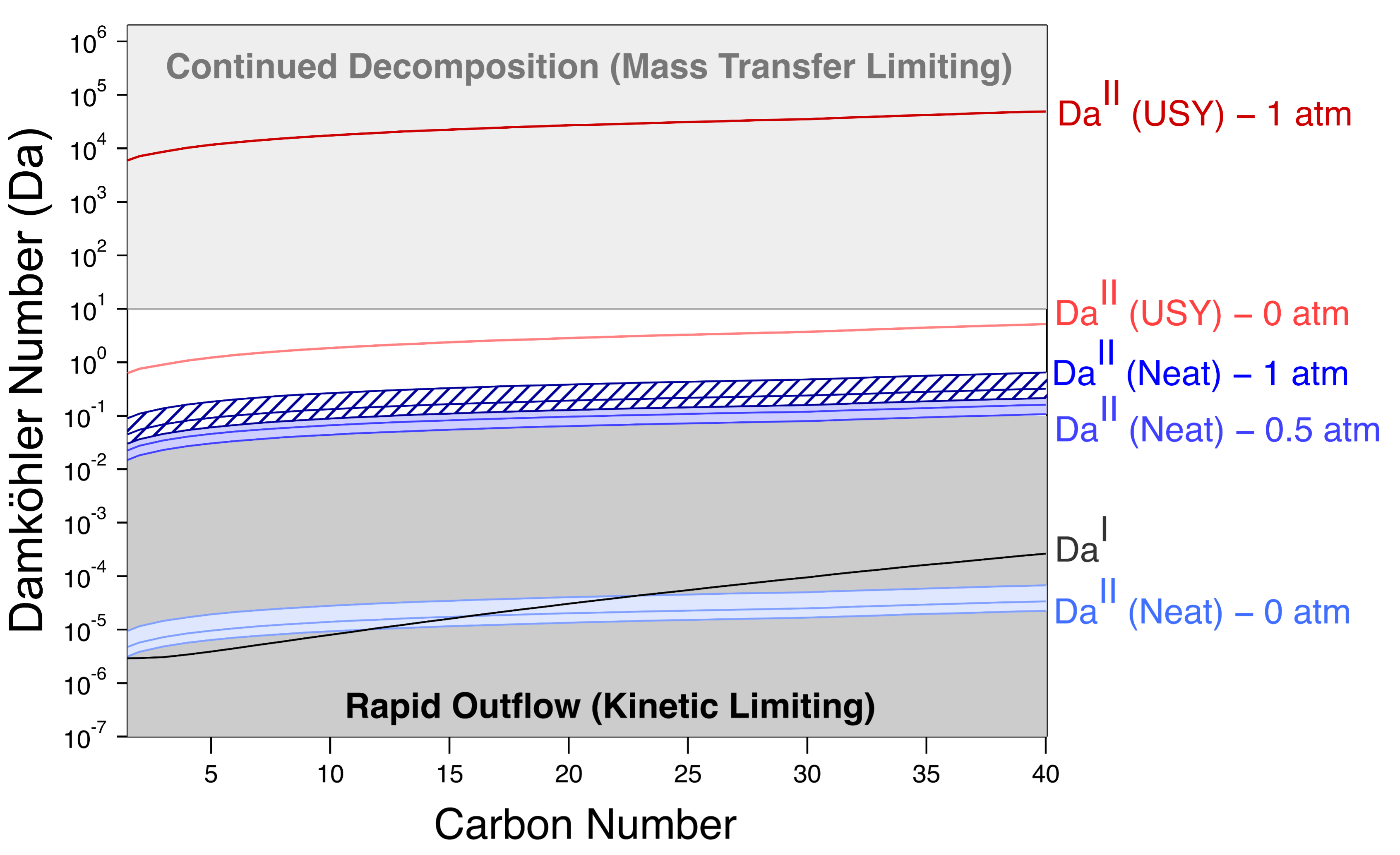

Pyrolysis offers a practical route for large-scale waste plastic treatment, particularly for polyolefins where other approaches do not offer success. However, varied product distributions often result, underscoring the complex interplay between chemical kinetics and mass transfer. In this work, we demonstrate the use of dimensionless Damköhler numbers to guide the modulation of chemical kinetics–mass transfer coupling in both neat and catalytic polyolefin pyrolysis for tuning product distributions. High-density polyethylene (HDPE) is selected as an illustrative example, and its pyrolysis was conducted at pressures between near vacuum and 1 atm in a microreactor to vary the mass transfer environments, with USY zeolite catalysts used to alter chemical kinetics. Our experiments revealed that neat pyrolysis at near-vacuum conditions gave a product distribution closer to that obtained from the kinetic-limited regime, representing primary products that readily escape from the reaction zone. Increasing pressure and adding catalysts both promoted HDPE conversion, caused by decelerated species outflow and increased reaction rate, respectively, facilitating continued decomposition of the primary products. Two dimensionless Damköhler numbers, DaI for the melt polymer phase and DaII for the headspace directly above the vapor–liquid interface, are defined to characterize the competition between mass transfer and continued decomposition of a species. It is shown that DaI is small for all experimental conditions studied (Fig. 1), suggesting fast escape of the products from the melt polymer phase. On the other hand, DaII suggests that higher system pressure or the presence of the catalyst favors continued decomposition in the headspace is favored. This Damköhler number analysis accurately predicts the experimental findings. Such a dimensionless analysis provides insights into future pyrolysis process optimization or novel catalyst design to manipulate chemical kinetics–mass transfer coupling in polyolefin pyrolysis for achieving desired product distributions, advancing plastic recycling technologies for full circularity.