2025 AIChE Annual Meeting

(646j) Controllable Production of Smaller Microbubbles Via Optimizing the Operation Procedure and Structure of the Flow-Focusing Microchannel

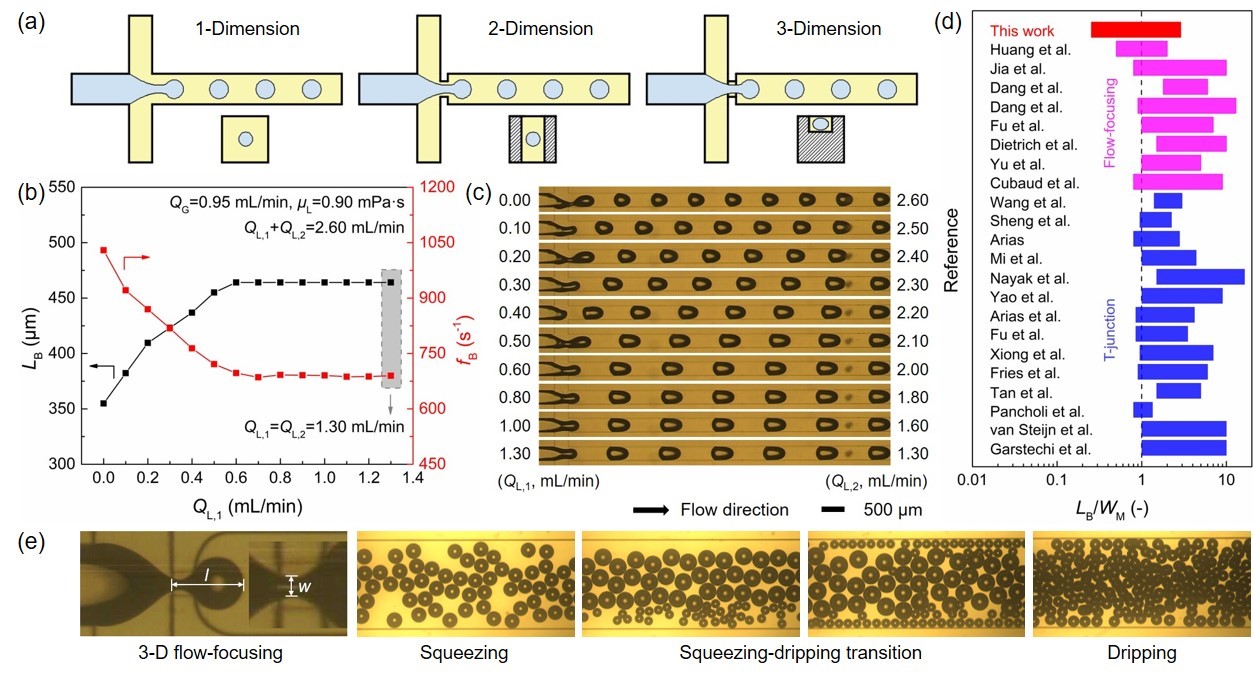

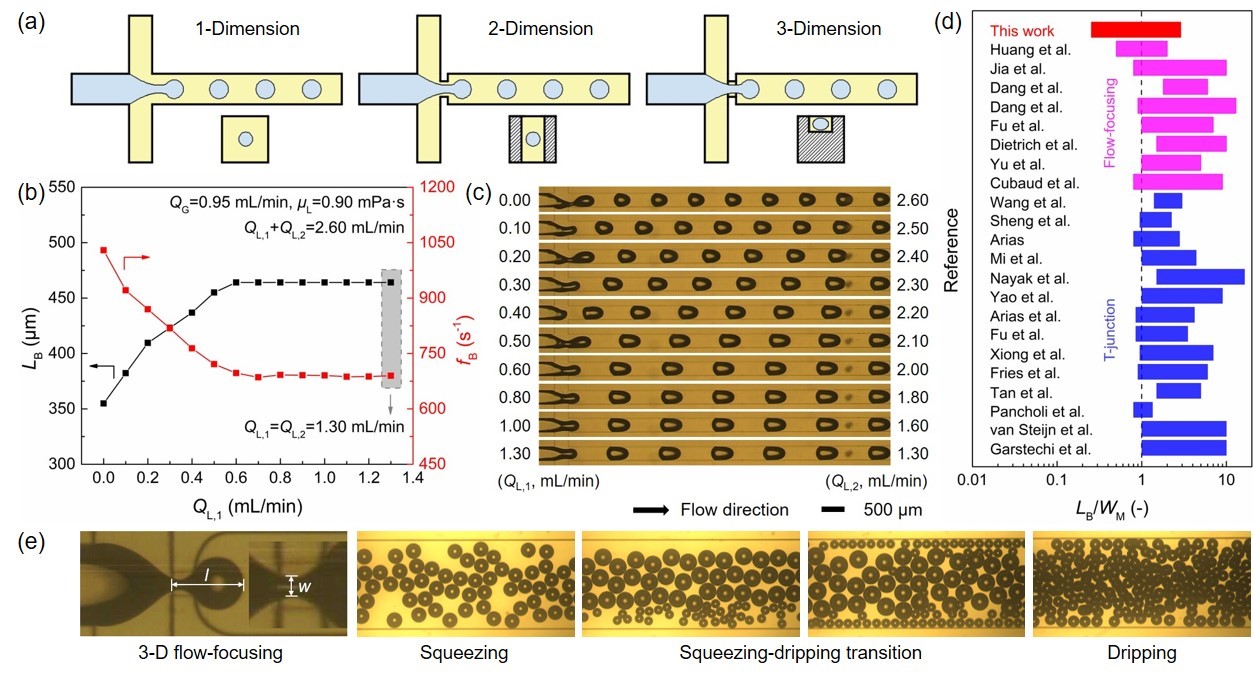

Production of smaller microbubbles benefits the promotion of the mass transfer performance in microchannels, but the existing methods focus on designing complex structures. This work proposes a novel asymmetric operation procedure of the 1-dimension flow-focusing microchannel to directly prepare smaller microbubbles without the structure modification. Under a given total liquid volumetric flux, the microbubble size could be obviously reduced with the increase in the liquid volumetric flux deviation between two side inlets (Fig. 1b-c). Importantly, the microbubble size can be decreased by 1 fold and the minimal bubble diameter is lower to 25% of the channel width (Fig. 1d), which breaks the bubble size bottleneck from the standard symmetric operation procedure of the 1-dimension flow-focusing microchannel. Further, based on the asymmetric operation procedure of the 1-dimension flow-focusing microchannel, we fabricated a 3-dimension flow-focusing microchannel (Fig. 1a). Compared with microbubble formation in 1-dimension and 2-dimension flow-focusing, the 3-D flow-focusing microchannel owns the features of making microbubbles with much smaller sizes and wider operation range. Four different gas–liquid flow regimes (squeezing, squeezing-dripping transition, dripping, and jetting) and three different gas–liquid dispersion states (mono-dispersion, bi-dispersion, and poly-dispersion) were observed in the 3-D flow-focusing microchannel (Fig. 1e). This work breaks the symmetric operation procedure and structure of the flow-focusing microreactor that lasted for 20 years, and it provides a new process intensification strategy for the microbubble preparation.