2025 AIChE Annual Meeting

(10b) Computer-Aided Molecular and Process Design for Ionic Liquid-Based Separation of Mixed-Refrigerants

Authors

While there are numerous ILs that can be synthesized, only a handful of ILs have been considered for HFC separation so far. Their large diversity in cation-anion combinations and molecular complexity, and nonlinear structure-property relationships make predictive modeling difficult. Traditional group-contribution or linear mixing rules for organic small molecules often fail due to the nonlinear electrostatic, hydrogen bond, and Van der Waals interactions within ILs and between ILs and solutes. Furthermore, CAMPD problems are inherently multiscale in nature, which leads to large-scale mixed-integer nonlinear programs (MINLP). These models are often computationally intractable due to high-dimensional molecular design space, complex thermodynamic property models [11], and highly nonlinear and nonconvex process models. An additional challenge arises when CAMPD is applied to systems with limited molecular data. Specifically, for ILs, experimental property data are sparse, and accurate thermodynamic data for solubility or phase equilibria are available for only a small fraction of the IL design space.

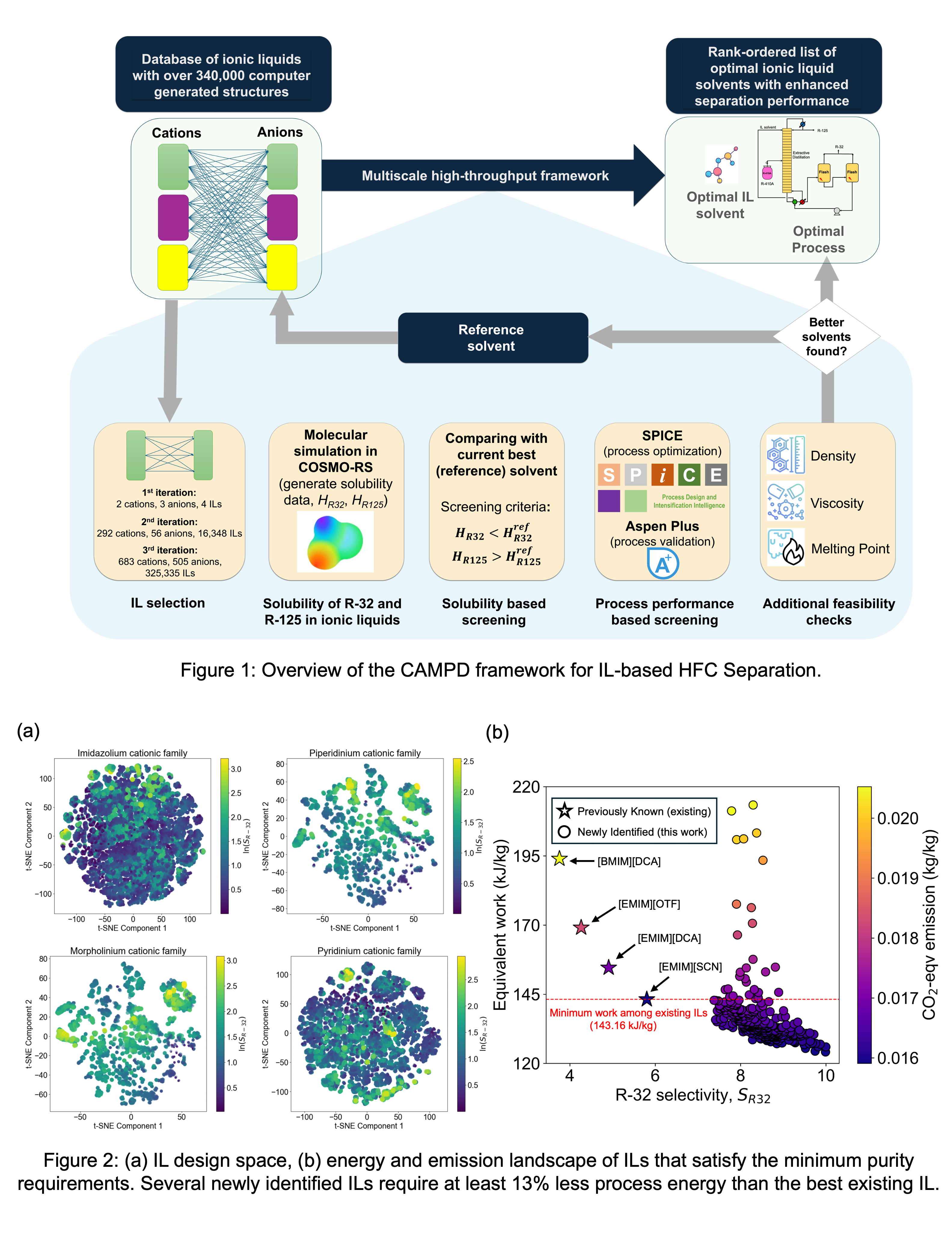

To address these challenges, we present a hierarchical, multiscale computational workflow for CAMPD that combines aspects of molecular simulation, machine learning, process performance measures, and equation-oriented process optimization for extractive distillation-based separation of mixed HFCs using ILs [12-14]. Our methodology (see Figure 1) involves a decomposition-based strategy that enables hierarchical intelligent reduction of the IL search space while ensuring process-level specification and feasibility. Decomposition enables us to divide the overall CAMPD into a set of smaller subproblems that can be solved sequentially [15]. These subproblems are defined for property prediction, molecular screening, and process optimization. A key contribution of our approach is the introduction of a reference IL in the solubility-based screening step that filters out suboptimal ILs by enforcing Henry’s constant-based constraints. By iteratively refining reference ILs across batches of IL candidates, we retain only the most promising IL molecules. For ILs identified through material-centric screening, we perform detailed process synthesis and optimization with the objective of minimizing the process energy consumption and CO₂ emissions under constraints on product purity (≥ 99.5 wt.%) and complete IL recovery. For property feasibility checks, we use machine learning-based property models to predict major IL properties including melting point, viscosity, and density. These models ensure rapid and generalizable estimation of critical properties across the vast IL space, thereby ensuring that the selected ILs satisfy the property bounds. We demonstrate the efficiency of the framework for the discovery of ILs for the separation of R-410A (an azeotropic mixture of R-32 and R-125), one of the commonly used HFCs today. We explore 341,687 ILs comprising 683 cations and 505 anions. By employing COSMO-RS-based molecular simulation, we estimate infinite dilution activity coefficients for R-32 and R-125, which are then used to compute Henry’s constants and selectivity. For process optimization, we use a building block-based approach [9]. As shown in Figure 2, this integrated CAMPD strategy led to the discovery of 285 novel ILs with optimized process configurations that provide at least a 13% reduction in energy requirement compared to the current best-existing ILs [12-13]. Our results underscore the important fact that material-centric screening based on selectivity alone could result in false positives. Many ILs may have high selectivity but they still may fail to meet process-level specifications. These false positives can be systematically eliminated through CAMPD.

Our work represents one of the largest and most comprehensive applications of CAMPD under data-scarce conditions and offers a generalizable strategy for other important solvent-based separation challenges. This framework demonstrates how data-driven and physics-based property models can be integrated to process modeling and optimization, thereby accelerating material discovery for sustainable chemical process design.

Keywords: Computer-aided molecular and process design, Machine learning, Molecular simulation, Optimization, Mixed-Refrigerants.

References:

[1] Gani, R. (2004). Chemical product design: challenges and opportunities. Computers & Chemical Engineering, 28 (12), 2441–2457.

[2] Gertig, C., Leonhard, K., and Bardow, A. (2020). Computer-aided molecular and processes design based on quantum chemistry: current status and future prospects. Current Opinion in Chemical Engineering, 27, 89–97.

[3] Adjiman, C. S., Galindo, A., and Jackson, G. (2014). Molecules matter: The expanding envelope of process design. Computer Aided Chemical Engineering. 34, 55–64.

[4] Papadopoulos, A. I., and Linke, P. (2006). Efficient integration of optimal solvent and process design using molecular clustering. Chemical Engineering Science, 61 (19), 6316–6336.

[5] Dowling, A. W. (2024). Artificial Intelligence and Machine Learning for Sustainable Molecular-to-Systems Engineering. Systems and Control Transactions, 3, 22-31.

[6] Booten, C. W., Nicholson, S. R., Mann, M. K., and Abdelaziz, O. (2020). Refrigerants: market trends and supply chain assessment. National Renewable Energy Lab (NREL), Golden, CO (United States).

[7] Asensio-Delgado, S., Viar, M., Pardo, F., Zarca, G., and Urtiaga, A. (2021). Gas solubility and diffusivity of hydrofluorocarbons and hydrofluoroolefins in cyanide-based ionic liquids for the separation of refrigerant mixtures. Fluid Phase Equilibria 549, 113210.

[8] Baca, K. R. et al. (2024). Ionic Liquids for the Separation of Fluorocarbon Refrigerant Mixtures. Chemical Reviews, 124(9), 5167–5226.

[9] Monjur, M. S., Iftakher, A., and Hasan, M. M. F. (2022). Separation process synthesis for high-gwp refrigerant mixtures: Extractive distillation using ionic liquids. Industrial & Engineering Chemistry Research, 61(12), 4390-4406.

[10] Baca, K. R., Olsen, G. M., Matamoros Valenciano, L., Bennett, M. G., Haggard, D. M., Befort, B. J., Garciadiego, A., Dowling, A. W., Maginn, E. J. and Shiflett, M. B. (2021). Phase Equilibria and Diffusivities of HFC-32 and HFC-125 in Ionic Liquids for the Separation of R-410A. ACS Sustainable Chemistry & Engineering, 10(2), 816-830.

[11] Befort, B. J., Garciadiego, A., Wang, J., Wang, K., Franco, G., Maginn, E. J. and Dowling, A.W. (2023). Data science for thermodynamic modeling: Case study for ionic liquid and hydrofluorocarbon refrigerant mixtures. Fluid Phase Equilibria, 572, 113833.

[12] Iftakher, A., Monjur, M. S., Leonard, T., Gani, R., and Hasan, M. M. F. (2025). Multiscale High-Throughput Screening of Ionic Liquid Solvents for Mixed-Refrigerant Separation. Accepted at Computers and Chemical Engineering.

[13] Iftakher, A., Monjur, M. S., Nahid, A., Dukissis, M., and Hasan, M. M. F. (2025). Combined Molecular Screening and Process Design Reveals Hundreds of New Ionic Liquids as Superior Solvents for HFC Separation. Under review at Chemical Engineering Journal.

[14] Iftakher, A., Leonard, T., and Hasan, M. M. F. (2025). Integrating different fidelity models for process optimization: A case of equilibrium and rate-based extractive distillation using ionic liquids. Computers and Chemical Engineering, 192, 108890.

[15] Karunanithi, A. T., Achenie, L. E., and Gani, R. (2005). A new decomposition-based computer-aided molecular/mixture design methodology for the design of optimal solvents and solvent mixtures. Industrial & engineering chemistry research, 44 (13), 4785–4797.