2025 AIChE Annual Meeting

(669h) Comparative Evaluation of Stationary Phases in Gas Chromatography for Effective Analysis of Complex Refrigerant Mixtures

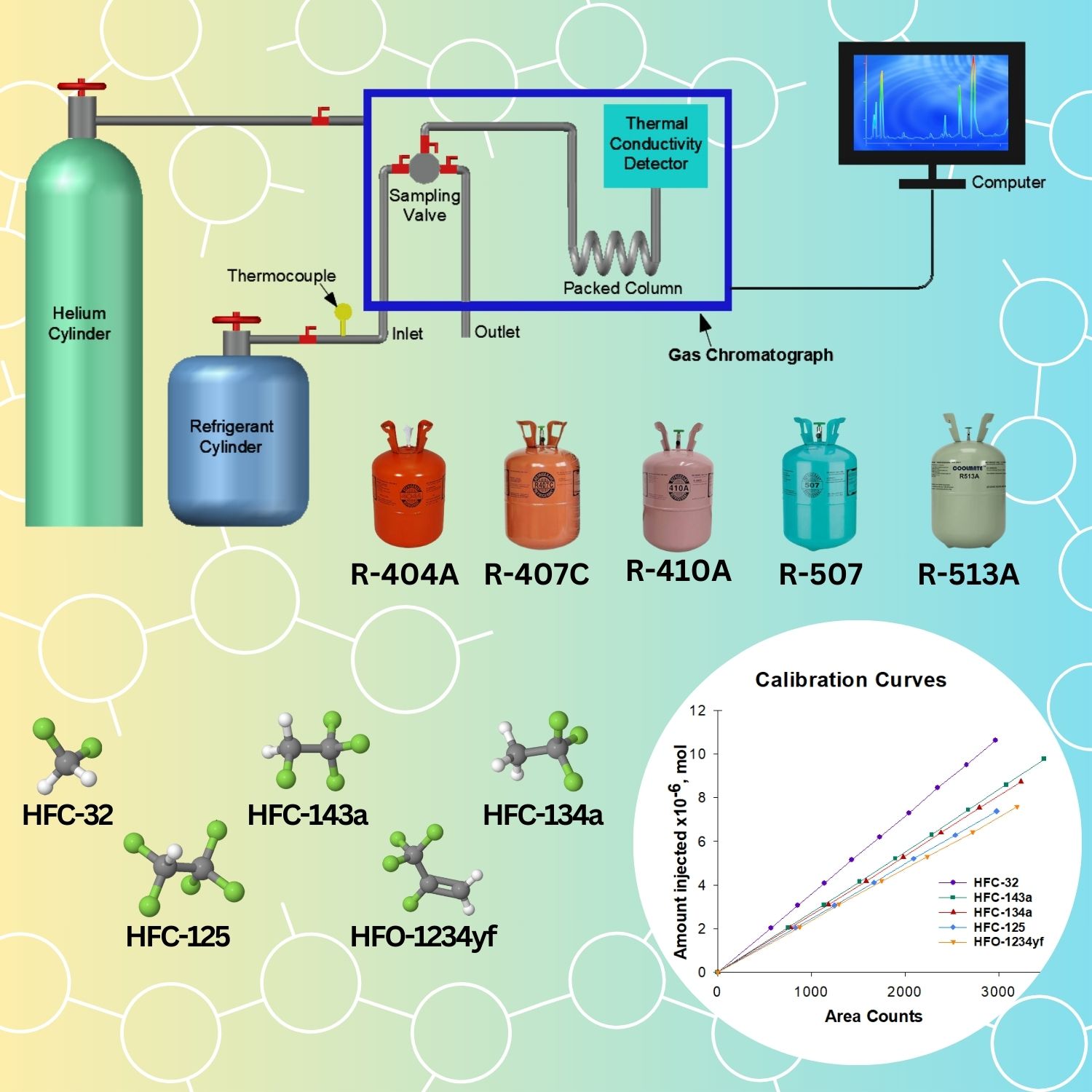

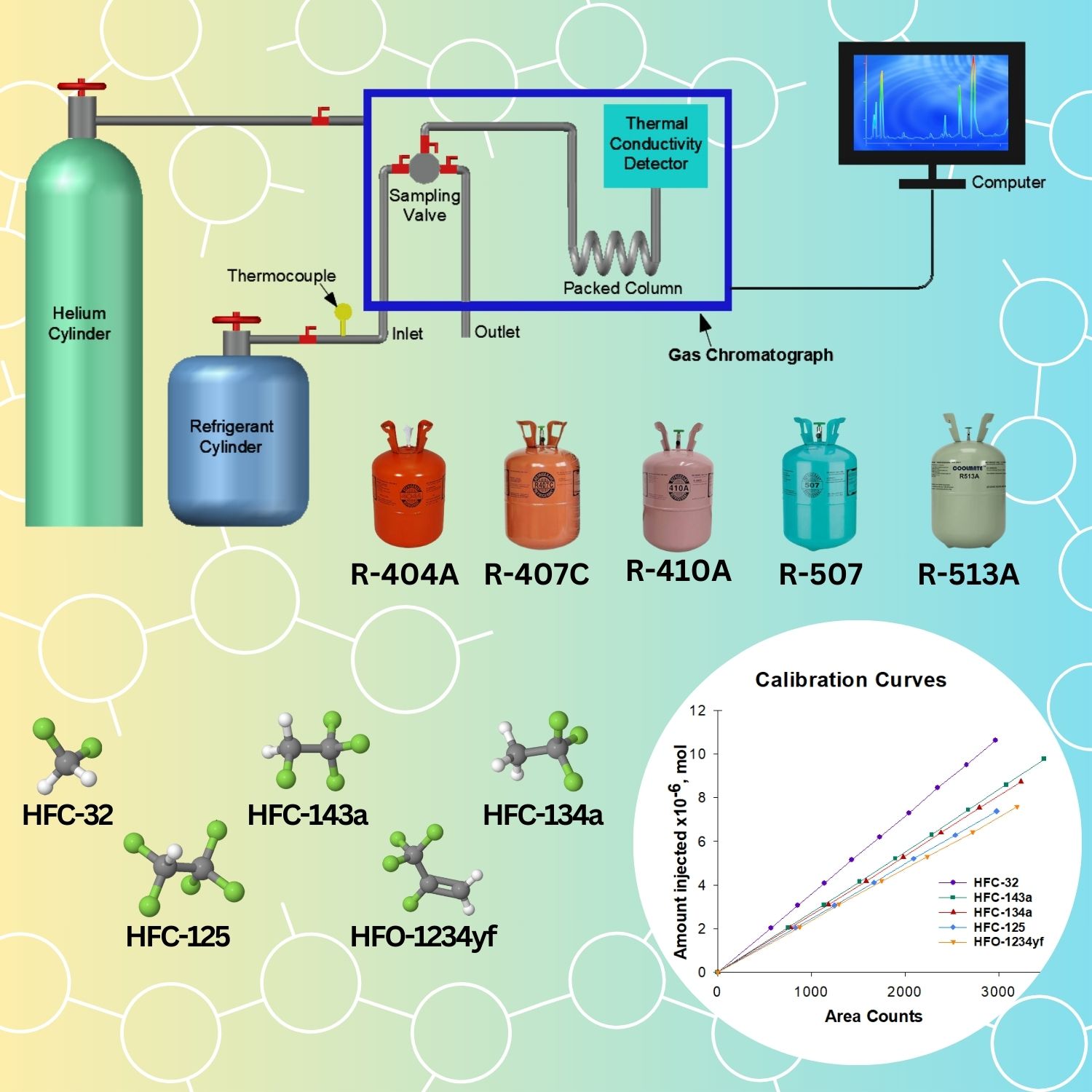

Regulations on hydrofluorocarbons (HFCs) have driven the advancement of technologies such as extractive distillation with ionic liquids to reclaim and separate HFC-based refrigerant blends. Achieving high-purity levels of 99.5% by weight is essential for recycling single-component HFCs with low Global Warming Potential (GWP) and repurposing phased-out HFCs as feedstocks for chemical transformation. Ensuring the success of this process requires precise and efficient analytical methods to assess the purity of recovered refrigerants. This study evaluates two stationary phases (HayeSep D and Carbopack B) for gas chromatography (GC) analysis of multicomponent refrigerant mixtures, including R-404A, R-407C, R-410A, R-507, and R-513A. Using a commercial GC system equipped with a thermal conductivity detector (TCD) and a sampling injection valve, single-component refrigerants HFC-32, HFC-125, HFC-134a, HFC-143a, and HFO-1234yf were analyzed to develop precise calibration curves. The influence of key GC parameters such as oven temperature and carrier gas pressure on peak separation and retention times was examined. Results indicate that the HayeSep D method outperforms Carbopack B, offering shorter analysis times, lower GC operating temperatures, less expensive supplies (e.g., GC column), lower standard deviations (≤0.63% by weight), and 95% confidence level error of ±0.08 to ±0.8 wt% by weight for all refrigerant mixtures. This study supports the scaling up of reclaimed refrigerant technology for Heating, Ventilation, Air Conditioning, and Refrigeration (HVA&R) companies, enhancing operational efficiency while significantly reducing laboratory testing time.