2025 AIChE Annual Meeting

(513b) Comparative Assessment of Integrated Green Methanol Synthesis Systems with Electrochemical CO2 Reduction and Hydrogen Production

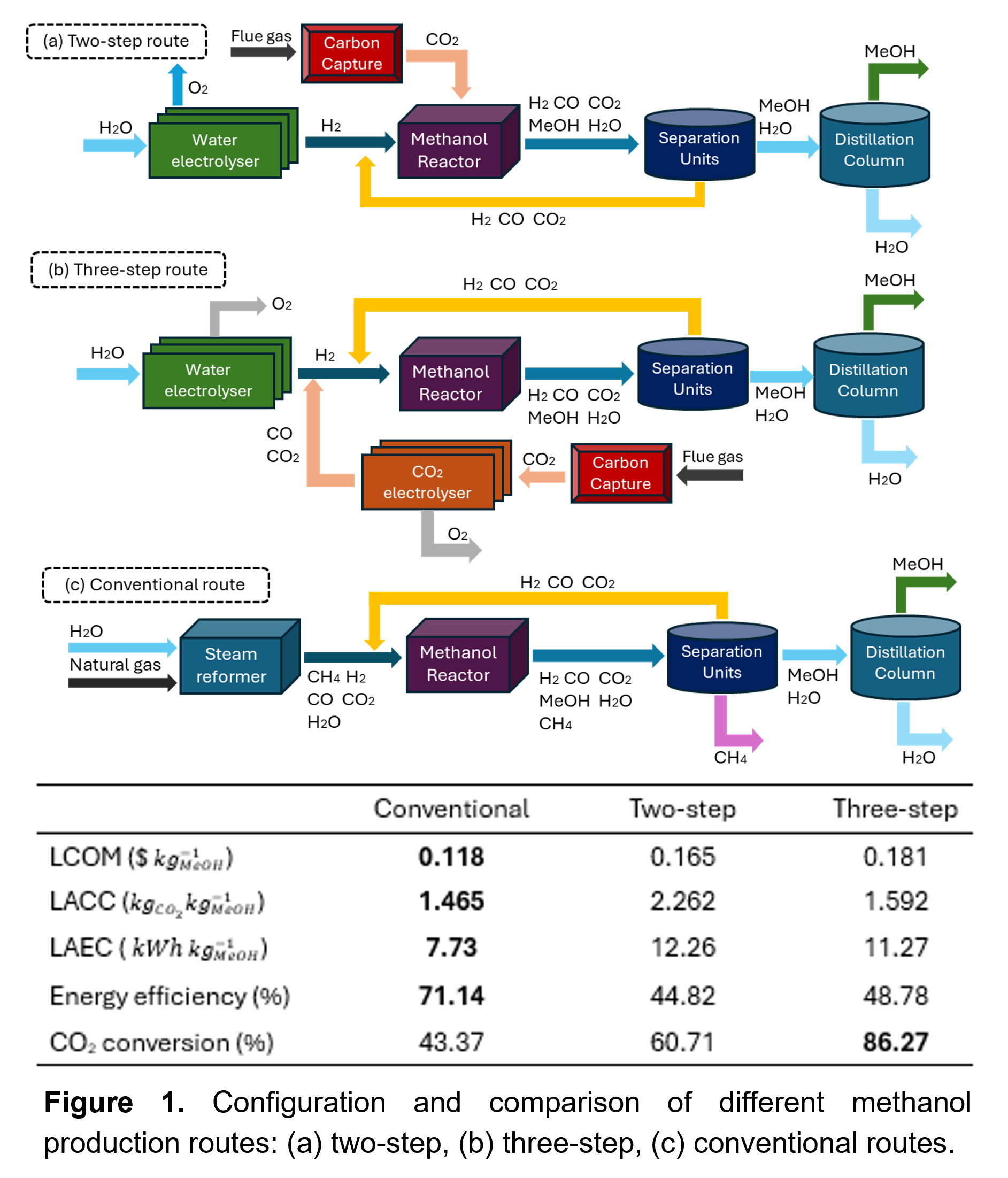

This study conducts a comparative assessment of various methanol synthesis routes that incorporate advanced electrolysers, providing an overview of their techno-economic analysis (TEA), CO2 uptake and energy consumption analysis, including (1) a two-step methanol synthesis starting from water electrolysis to produce H2, followed by CO2 hydrogenation; (2) a three-step synthesis involving water electrolysis for H2 production, CO2 electrolysis to produce CO, and subsequent hydrogenation of CO2 and CO, (3) a conventional thermochemical methanol synthesis route using natural gas reforming. All technical routes are electrified, with the energy needed for thermal and electrochemical reactions supplied by electricity generated from renewable sources.

For the two-step and three-step routes, we developed a novel two-scale system model that integrates data-driven surrogate models of two electrochemical processes, i.e., CO2 and water electrolysis, into system-level mass and energy balances, building a robust system model. This approach links the variation of Faraday efficiency, conversion and product yield with the operating conditions of these processes, significantly improving the model's accuracy and explainability. Symbolic regression (SR) is employed as a data-driven model to represent the relationship between operating variables and key metrics of electrolysers. To evaluate system performance, several key performance indicators (KPIs) have been developed, including the levelised cost of methanol produced (LCOM), the levelised amount of CO2 uptake per unit of methanol produced (LACC), and the levelised amount of renewable electricity consumed per unit of methanol produced (LAEC).

The results show that the conventional methanol synthesis route is the most cost-effective, costing $0.118 and consuming 1.465 kg CO2 per kg of methanol produced, with a high energy efficiency of 71.14% but the lowest CO₂ conversion of 43.37%. The two-step method, with an increase cost to $0.165 per kg of methanol produced and improving CO2 conversion to 60.71%, still requires optimisation to increase the energy efficiency. The three-step route achieves the highest CO2 conversion at 86.27% and delivers satisfactory results with a levelised cost of $0.181 per kg of methanol produced. However, it is at the expense of higher energy consumption and a relatively low energy efficiency of 48.78%. Furthermore, the levelised amount of renewable electricity consumed per unit of methanol produced is minimal in the conventional route but highest in the two-step route. With the continued reduction in renewable energy prices and the maturation of electrolysis technology, the three-step route holds significant potential to replace conventional thermochemical methanol synthesis.

The analysis suggests that the three-step route could become viable in the medium term, bolstered by the implementation of new European policies. This system-level comparative analysis establishes a framework for optimising green methanol production technologies. By integrating advanced surrogate models into system-level models, the study introduces a robust two-scale simulation framework for analysing and optimising green methanol production systems. This provides valuable insights for scaling these technologies and enhancing their commercial viability in the future.