2025 AIChE Annual Meeting

(184j) Chitosan-Based Stretchable and Biodegradable Substrates for Sustainable Soft Electronics with Recyclable Silver Nanowires

Authors

Mesbah Ahmad - Presenter, North Carolina State University

Darpan Shukla, North Carolina State University

Orlin D. Velev, North Carolina State University

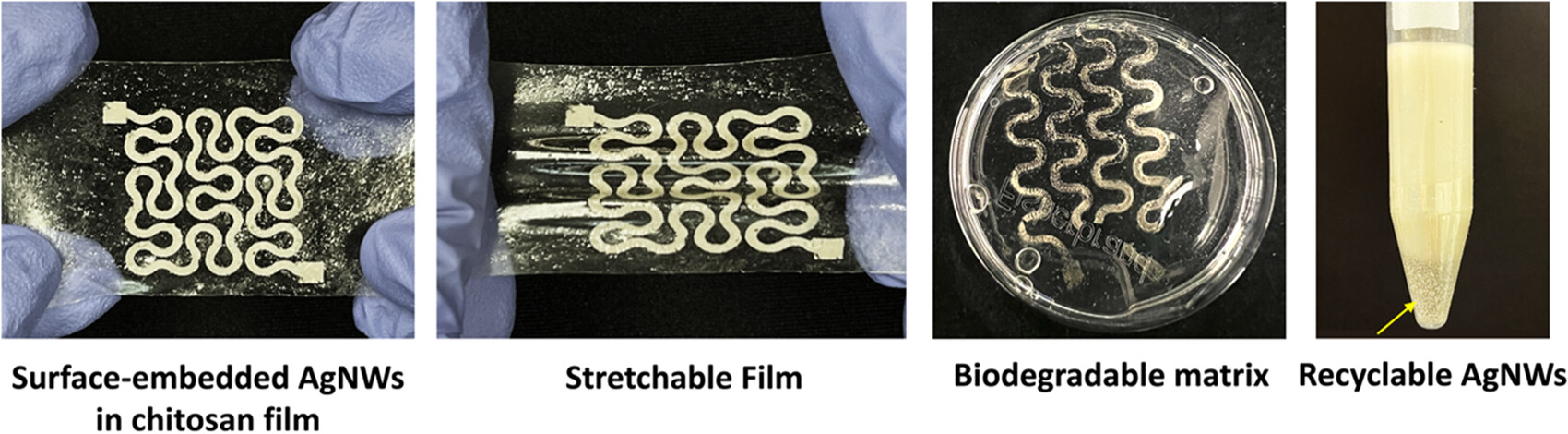

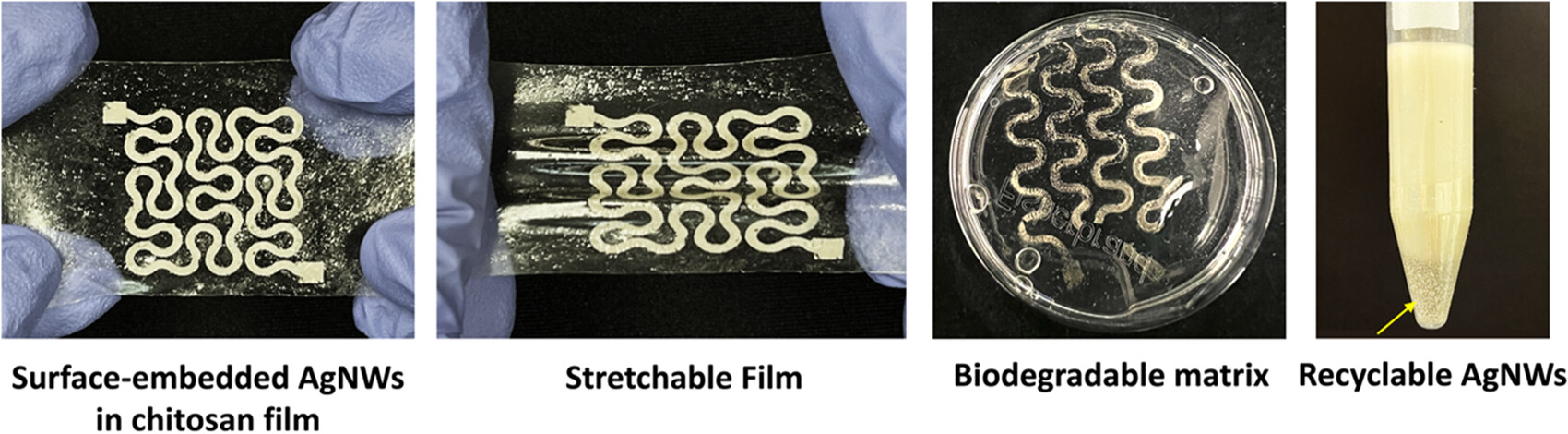

Biodegradable and stretchable substrates offer a promising route to replace synthetic and nonbiodegradable substrates in soft electronics and reduce the environmental impacts of electronic waste. The combination of biodegradability and biocompatibility makes chitosan a major bioresourced material in biomedical engineering, wearable technology, and medical diagnostics, particularly for integration in human interfaces for soft electronic applications. Biopolymer plasticization can be an effective method for engineering soft substrates. In this study, chitosan films were plasticized using glycerol to improve their mechanical flexibility and stretchability. Glycerol disrupts the large number of hydrogen bonds among the chitosan chains and forms new intermolecular hydrogen bonds with them, enhancing chain mobility. The resulting films exhibited remarkable elongation at break (~110%), having Young’s modulus of the same order of magnitude as human skin. The films exhibited high optical transparency and an elevated water vapor transmission rate, allowing sweat vapor to pass through and ensuring comfort when in contact with the user's skin. These properties make them well-suited as substrates for wearables. The swelling behavior and mass loss due to water uptake and glycerol leaching were characterized to understand the internal interactions of the plasticized matrix. Silver nanowires (AgNWs) were incorporated to fabricate conductive patterns in stretchable electronic circuits. Health and motion monitoring devices such as EMG and strain sensors were developed using chitosan-based substrates. The biodegradability of the devices was demonstrated through enzymatic degradation using lysozyme. Following degradation of the chitosan substrate, AgNWs were recovered and shown to retain their functional properties, enabling reuse in subsequent device fabrication. This work shows the potential of chitosan-glycerol films as a stretchable, transparent, and biodegradable substrate for soft electronics, where both substrate and functional components can be sustainably managed at their end of life.