2025 AIChE Annual Meeting

(38g) CFD Simulation of Pulsed Fluidization of Cohesive Geldart C Particles Using an Agglomeration-Enhanced Two-Fluid Model

Authors

Fluidization of fine cohesive powders (Geldart C particles) is important across many industrial applications, including pharmaceuticals, chemical synthesis, energy production, and cement manufacturing. Despite their desirable properties, such as high surface area and reactivity, these particles typically exhibit poor fluidization performance due to strong interparticle cohesive forces, including van der Waals and electrostatic attractions [1]. These cohesive interactions result in agglomeration, channeling, and uneven particle distribution, significantly reducing process efficiency and product quality. Various techniques, such as mechanical agitation, acoustic vibration, and chemical additives, have been employed to address these fluidization challenges. Recently, pulsed fluidization, characterized by intermittent gas flow, has emerged as a promising alternative due to its simplicity, energy efficiency, and effectiveness in disrupting particle agglomerates [2].

However, the mechanisms underlying pulsed fluidization are not yet fully understood. Computational Fluid Dynamics (CFD) simulations have the potential to significantly enhance our understanding and optimization of pulsed fluidization processes. Nonetheless, conventional CFD approaches typically fail to accurately simulate cohesive particle behavior under pulsation, emphasizing the need for more advanced models. This study aims to develop and validate an enhanced CFD model capable of accurately simulating the fluidization of cohesive Geldart C particles under pulsation, thereby improving industrial fluidized bed processes involving cohesive powders [3].

Methods

In this study, an advanced CFD approach is developed by integrating an agglomeration model into the conventional two-fluid model (TFM), combined with the kinetic theory of granular flow (KTGF). The enhanced CFD model was implemented using ANSYS Fluent, utilizing user-defined functions to dynamically simulate the formation and breakage of particle agglomerates based on a comprehensive force balance (Fdrag + Fcollision + Fresonance = Fgravity & buoyancy + Fcohesive) approach.

The model was validated using experimental data from a lab-scale pulsed fluidized bed utilizing cement raw meal (Geldart C). The focus was on determining the Minimum Mixing Velocity (MMV), the gas velocity at which particles begin moving relative to each other, as this provides a more reliable indicator of fluidization quality for cohesive materials compared to the traditional Minimum Fluidization Velocity, which is unreliable due to irregular pressure signals caused by channeling and pulsation effects [4]. In both experiments and CFD simulations, MMV was identified by incrementally increasing gas velocity until particle mixing without stagnant regions was visually confirmed (experimentally) or when the minimum solid velocity became nonzero (simulations). Key pulsation parameters explored included frequency (f = 0.5–16 Hz), Closed-to-Open time ratio (C/O = 0.5–15), and Pulsed-to-Continuous flow ratio (P/C = 0–∞), covering a wide range of conditions in both experimental and CFD studies.

Results and Discussion

The developed CFD model demonstrated significant improvements over conventional TFM–KTGF simulations, reducing the error in Minimum Mixing Velocity (MMV) predictions from approximately 96% to about 15% compared to experimental data. This notable enhancement underscores the importance of accurately incorporating cohesive forces and pulsation effects in CFD models for cohesive particle fluidization.

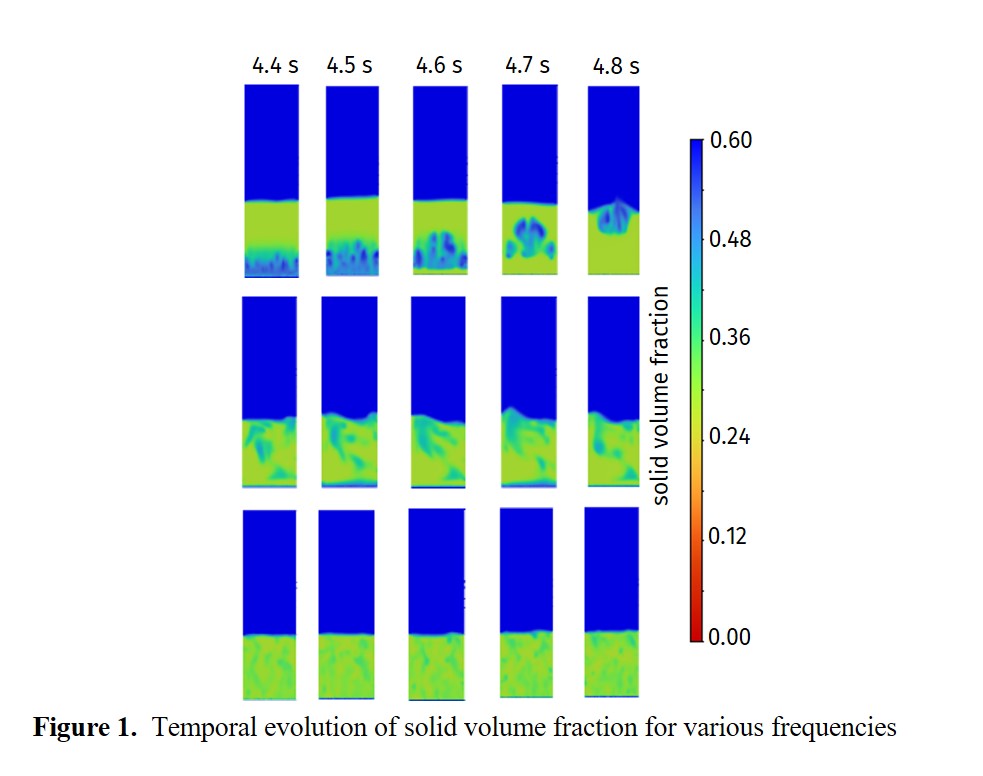

Both CFD simulations and experimental observations revealed that increasing the C/O and P/C notably reduced the MMV, effectively disrupting agglomerates and improving particle mixing. Pulsation frequency exhibited a more nuanced effect, with optimal fluidization performance identified at intermediate frequencies (1–5 Hz).

Further detailed CFD analysis, including radial distributions of solid volume fraction as well as solids and gas flux, provided deeper insights into the fluidization dynamics under pulsation. As an example, Figure 1 illustrates the temporal evolution of solid volume fraction within the fluidized bed at various pulsation frequencies. At lower frequencies, the formation of large bubbles created localized regions of low solids concentration, potentially compromising effective gas–solid contact. Conversely, higher frequencies facilitated more uniform particle distribution.

Significance

The enhanced CFD model presented here accurately predicts the fluidization behavior of cohesive Geldart C particles under pulsed conditions. By effectively capturing agglomeration dynamics and pulsation effects, the model helps industries improve process efficiency, reduce energy use, and enhance product consistency.

References

- Zhou, Y. and Zhu, J., Powder Technol. 381, 698 (2021).

- Ireland, E., Pitt, K., and Smith, R., Powder Technol. 292, 108 (2016).

- Askarishahi, M., Salehi, M.S., and Radl, S., Ind. Eng. Chem. Res. 61, 3186 (2022).

- Gupta, R. and Mujumdar, A.S., Can. J. Chem. Eng. 58, 332 (1980).