2025 AIChE Annual Meeting

(38a) CFD-DEM Modeling of Fluidized Bed Granulator (FBG): Granule Formation, Identification, and Evolution of Granule Size Distribution

Authors

During the granulation process, the addition of liquid binder promotes the formation of numerous particle clusters known as embryos. However, not all embryos possess enough stability to sustain their shape and size in an agitated fluidized bed environment. Some embryos disintegrate immediately upon formation or after collisions with other particles/embryos. The granules, therefore, can be defined as embryos that are rigid enough to sustain their shape and size in a dynamic environment.

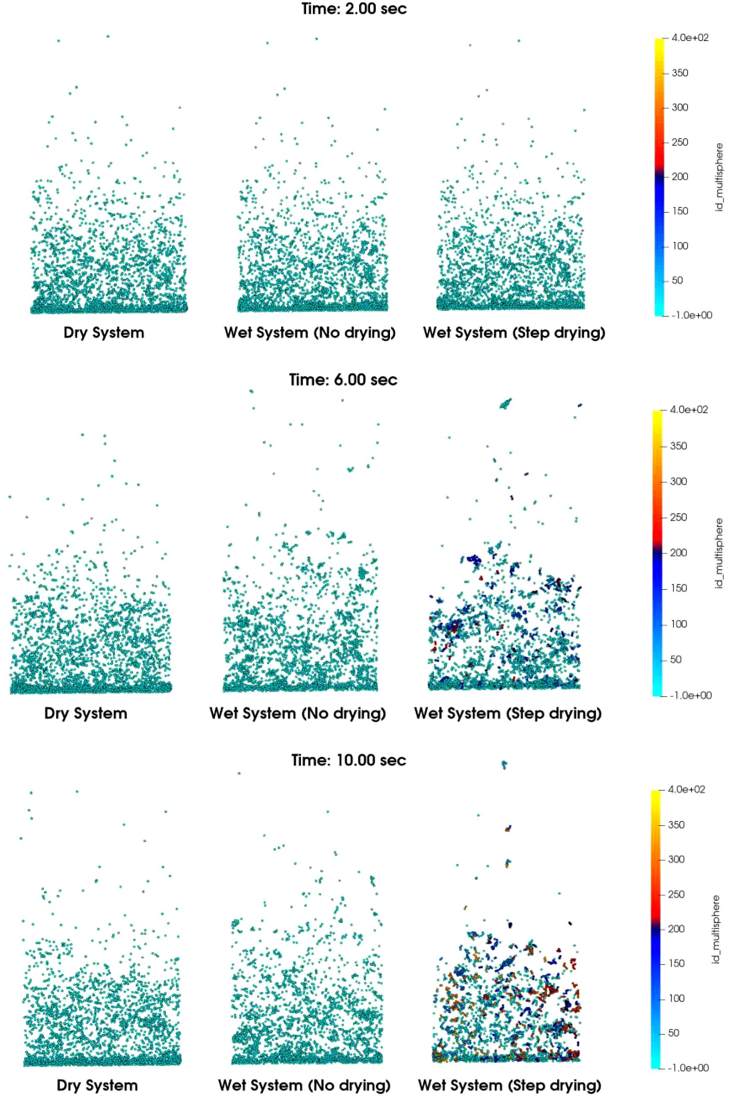

To distinguish such stable granules from transient embryos and obtain the evolution of granule size distribution, the algorithm evaluates particle pairs based on contact history and surface liquid content. Only those particle pairs that satisfy both criteria are identified as stable granules and are represented using the multi-sphere model. The multi-sphere representation of granules corresponds to the drying modeled as a step function, resulting in the rapid solidification of liquid bridges.

This granulation model, incorporating the CFD-DEM framework and proposed granule identification algorithm, was implemented in a pseudo-2D fluidized bed, where wet particles were sprayed from the top. The formation and growth of granules were monitored and quantified using the proposed approach. The comparison between dry and wet fluidization (with and without granule identification algorithm) is shown in Fig. 1. The temporal evolution of granule size distribution was analyzed. Furthermore, the effects of key process parameters, including fluidization velocity and liquid binder properties (such as liquid content, viscosity, and surface tension), were investigated. The simulation results agreed qualitatively well with the experimental data reported in the literature.