2025 AIChE Annual Meeting

(152c) CFD-DEM Modeling of Floating Particle Suspensions in Mixing Processes

Authors

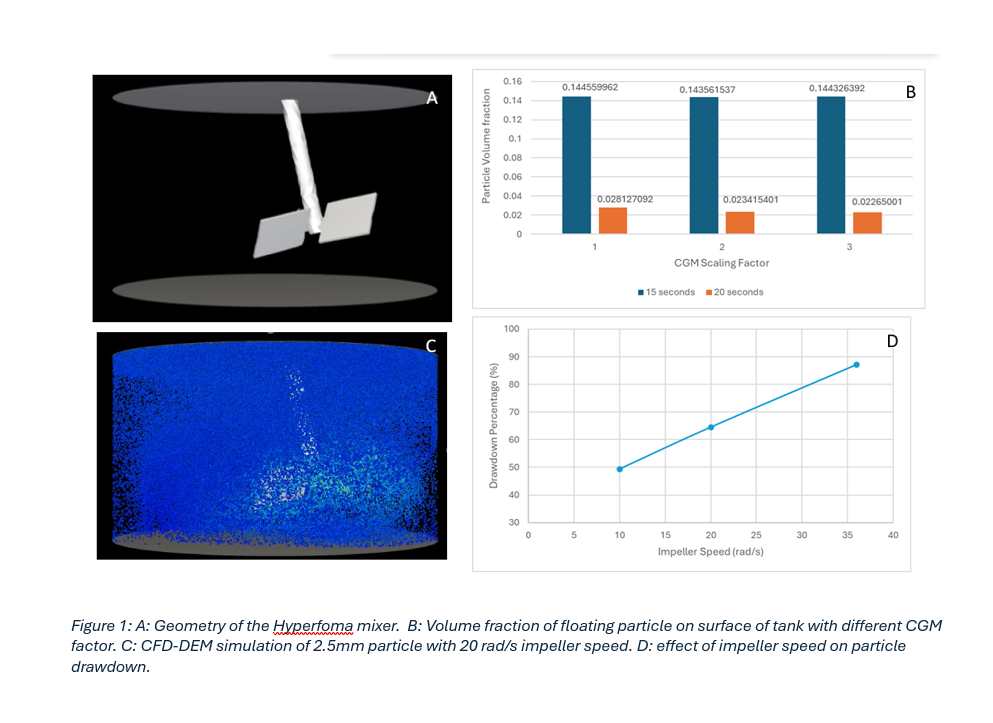

Mixing is a vital unit operation used in a wide range of industries, including chemical manufacturing, food and beverage production, pharmaceuticals, etc. Mixing offers benefits such as uniform composition and improved dissolution of components. Specifically, Solid-liquid mixing is a crucial component of industrial production procedures which can be categorized by particle density. This classification separates the process into two groups: the suspension of denser particles than fluid and the dispersion of floating particles with lower density than fluid. In this study, we used a coupled computational fluid dynamic (CFD) and Discrete Element Method (DEM) approach to model floating particle mixing in a HyPerforma mixing tank by integrating fluid flow equations with discrete particle interactions. This method provides a powerful tool to investigate and optimize complex multiphase flows, reducing the time, cost, and material requirements associated with experimental studies.

Methods:

An Eulerian-Lagrangian approach was employed to model solid-liquid mixing, where the fluid phase is treated in a continuum framework and each particle is tracked at a discrete level. This coupled CFD-DEM technique offers valuable particle scale insights, making it well-suited for analyzing mixing and segregation. Although several researchers have applied CFD-DEM to various mixing processes, limited literature exists on modeling the floating particles. To address this gap, we developed a model using ANSYS FLUENT and ROCKY to examine the mixing and segregation behavior of solid particles.

Results:

Simulations with different impeller speeds, particle sizes, and particle concentrations were performed. It was observed that increasing the impeller speed and particle concentration improved the drawdown and distribution of the floating particles. However, increasing the particle size led to a reduction in drawdown and distribution across the mixing tank due to the increase in particle inertia. Additionally, simulations were performed using coarse-grain modeling to generate results for cases with micron-sized particles. The advantage of coarse-grain modeling is that it reduces the number of particles in the simulation, which in turn decreases computational resource requirements.

Conclusion:

The coupled CFD-DEM approach proved effective in modeling the behavior of floating particles and identifying key factors such as impeller speed, particle size, and particle concentration that influence mixing performance. By combining fluid flow equations with discrete particle dynamics, this approach delivers essential insights at the particle scale while offering a robust, scalable solution for process design and optimization. Consequently, the framework contributes to more efficient, cost-effective, and reliable pharmaceutical manufacturing.