2025 AIChE Annual Meeting

(56e) Catalysis of Flare Gas to High Octane Gasoline

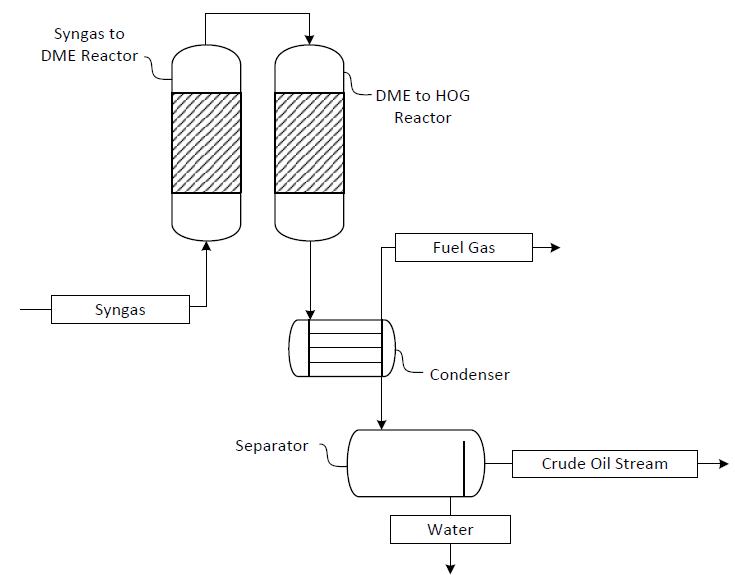

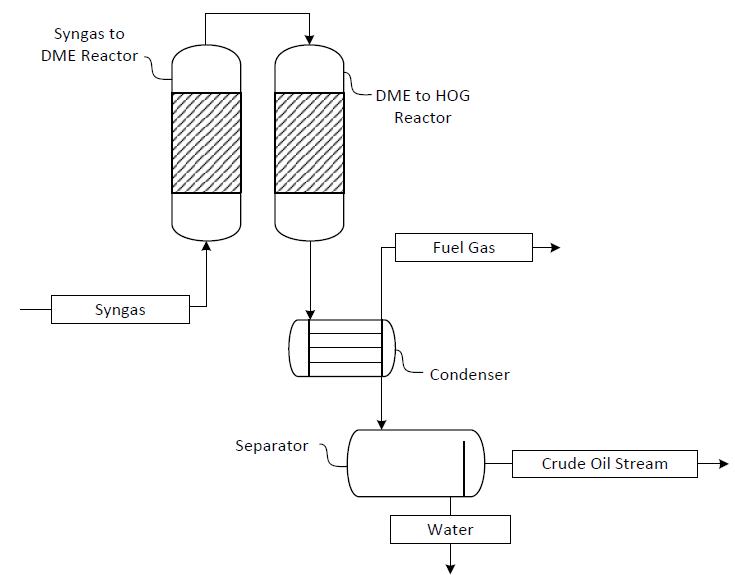

About 1-5% of the total feed from oil wells are vented and flared. For offshore cases, it is especially difficult to transport the vapor in lieu of flaring. To reduce the environmental impact of these flares and valorize these hydrocarbons, it is proposed to use a novel catalyst to convert flare gas to high octane gasoline. This new catalyst is advantageous because it shows higher selectivity away from aromatics which allows for longer catalyst lifetime and easier operation, its higher activity reduces the equipment footprint on the platform, and the products lead to a liquid stream with a Research Octane Number of 90-100. This reaction operates at a range that compliments commercial syngas to dimethyl ether processes to further reduce the capital needs. With this technology, GHG emissions from offshore flaring could be reduced by over 30%.