2025 AIChE Annual Meeting

(147h) Birch-Bark Suberin-Reconstructed Polyester Film As Packaging Materials

Authors

Nature, however, might provide promising alternatives, developed through millions of years of evolution. Cutin and suberin are two bio-polyesters composed of long-chain ω-hydroxy fatty acids cross-linked with glycerol. They contribute to regulate the water and gas exchange in plants, thus, they are essentially natural barrier materials. In northern Europe, the forest industry generates large quantities of suberin-rich bark as a byproduct, currently only exploited for energy production. This biomass holds the potential to become a renewable feedstock for bio-based, nature-inspired barrier materials. Such materials align with the United Nations’ Sustainable Development Goals (SDGs), promoting responsible consumption by utilizing industrial side streams (Goal 12) and potentially reducing marine pollution by replacing fossil-based plastics (Goal 14). While suberin monomers have been used in coatings for cellulose sheets and wood, as well as in thermoset production, the purification processes implemented are energy-intensive and rely on environmentally harmful solvents.

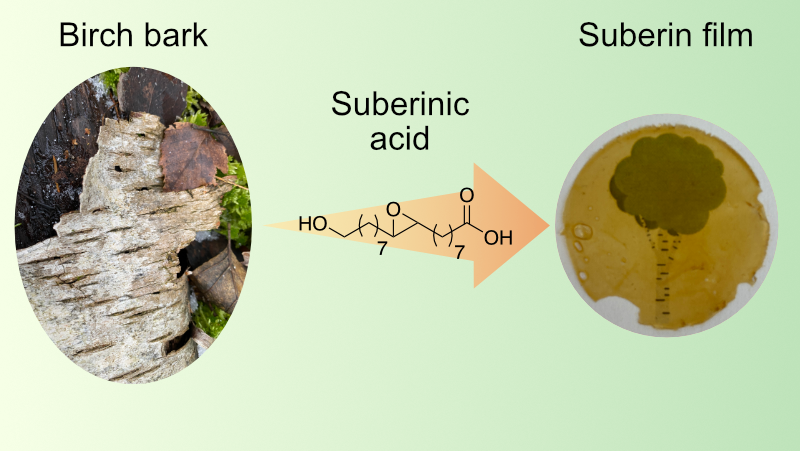

This study presents the development of a suberin-inspired, flexible, and thin film designed as a packaging material. Birch bark was selected as the raw material due to its high suberin content. Established protocols for the bio-polyester extraction and depolymerization were followed, while implementing modifications to minimize the extent of purification and aim to use of a more "crude" fatty acid mixture. The film synthesis was designed to ensure compatibility with conventional polymer processing techniques. The process involves an initial melt-polycondensation step, followed by thermoforming and final curing, all conducted in air without the use of solvents.

Extensive characterization of the chemical structure was conducted before, during, and after the synthesis process, primarily using ¹H NMR and FT-IR spectroscopy. These techniques allow to monitor the evolution of the esterification reaction, thus, the formation of the polyester network. Differential Scanning Calorimetry (DSC) thermograms confirmed the development of a cross-linked polymer network, observation supported by the film behavior during tensile testing which resulted to be elastomer-like, consistent with the presence of cross-links in the material.

The water vapor transmission rate (WVTR) was found to be comparable to that of short-chain polyesters such as polylactide (PLA) and polycaprolactone (PCL), both commonly used in packaging applications. Additionally, the material demonstrated excellent ultraviolet (UV) light-blocking properties and remained thermally stable up to 200°C, indicating the absence of unreacted monomers that could migrate into packaged goods. These findings suggest that the material holds strong potential for food packaging applications.

This study demonstrates the feasibility of producing a water vapor barrier film from a non-refined mixture of suberin-fatty acids using traditional polymer processing techniques. Furthermore, it reinforces the idea that bark, a widely available byproduct of the forest industry, has significant potential beyond energy production.