2025 AIChE Annual Meeting

(501a) Beyond the Limits of Conventional Ammonia Synthesis: Enhancing Single-Pass Conversion and Unlocking Load-Flexible Operation Via Polytropic Fixed-Bed Reactors

The Power-to-Ammonia concept is a promising approach for global, chemically based storage and transportation of renewable energies[1]. However, the use of electrolytically produced hydrogen as a reactant presents new challenges to the ammonia synthesis process. These challenges mainly arise due to the intermittent nature of renewable energy supply, which leads to volatile process inputs, e.g., changing hydrogen feed flows from dynamically operated electrolyzer units. To reduce costly intermediate reactant storage, an ammonia synthesis reactor concept is required that performs well, safe, and efficiently not only at a fixed nominal load but also across a wide load-range as well as under dynamic conditions (load-flexibility).

Conventional heat integrated, Adiabatic Quench-Cooled multi-bed Reactor (AQCR) systems (i.e., autothermal reactor concept) are known to be prone to oscillatory behavior under changing loads[2-4]. While advanced control strategies can improve process stability, handling changing loads, especially ramping the reactor from low to high loads, is still challenging and time consuming due to the high thermal inertia of adiabatic reactors[3]. Moreover, even in state-of-the-art ammonia synthesis reactor types, single-pass conversion remains relatively low, at approximately 15 to 20 %. Thus, this study focuses on numerical simulation studies to identify alternative reactor and operating concepts to enhance single-pass conversion and to enable load-flexible ammonia synthesis. One promising approach, but so far unexploited for ammonia synthesis, is the use of polytropic fixed-bed reactors, as recent studies on CO2 methanation reveal that these are particularly better suited for dynamic operation compared to autothermal concepts[5].

Methodology

For the mathematical description of the polytropic fixed-bed reactor (EDCR: External Direct Cooled Reactor), a two-dimensional dynamic pseudo-homogeneous reactor model, considering heat and mass dispersion, is developed. Activity-based kinetic models are chosen to describe the reaction rate on two different catalyst: (i) a former commercially used magnetite-based iron catalyst[6] and (ii) a modern industrial iron catalyst from the company Clariant AG[7]. Furthermore, a catalyst effectiveness factor is incorporated to account for temperature-dependent intraparticle mass transport limitations, pressure loss is described by the Ergun equation, and gas densities are calculated via the Peng-Robinson equation of state. To solve the reactor model, the PDE system is discretized in its spatial domains by applying the finite volume method. The resulting DAE system is solved in MATLAB using the IDAS integrator from the SUNDIALS suite. Based on detailed numerical simulations studies the potential of EDCR operation in terms of single-pass conversion and load-flexibility is evaluated and compared to a state-of-the-art AQCR.

Selected Results

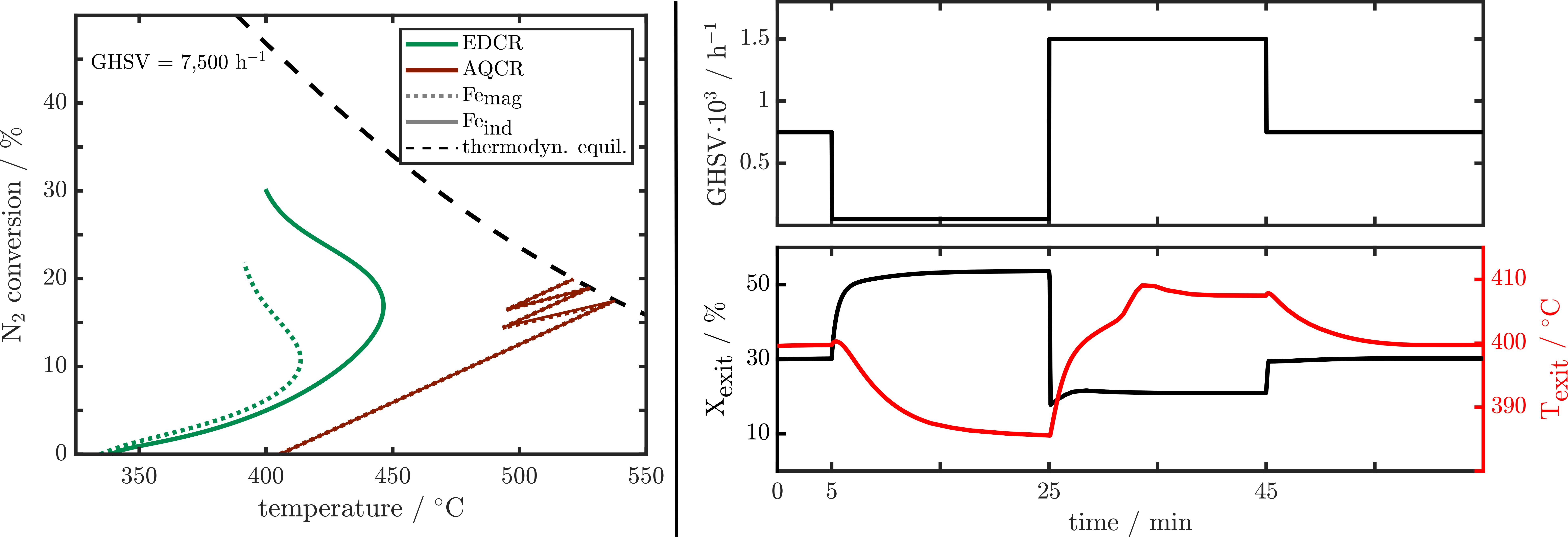

The simulation results indicate that adiabatic operation is strongly limited by the chemical equilibrium (Figure 1, left). Even when using more active catalyst, single-pass conversion is only marginally increased to about 20 % as elevated inlet temperatures are still required to ignite the reaction. In contrast, the EDCR concept benefits greatly from the deployment of more active catalysts, enhancing single-pass conversion from 22 to 31 % - and potentially up to 55 % by additionally reducing the GHSV[8]. Crucial for economical viable EDCR operation is the higher activity of modern ammonia synthesis catalyst at temperatures between 400 and 450 °C. This enables the use of simpler heat transfer fluids such as thermal oil. Whereas in adiabatic operation heat is supplied to the reactor only by convection and reaction, in polytropic operation a sufficient amount of energy is transferred to the fluid mixture through the cooling jacket. Consequently, the thermal inertia of the heavy catalyst packing has a significantly less dominant influence in the EDCR, enabling the polytropic reactor to exhibit noticeably improved dynamic behavior. In particularly, we found that the EDCR can be operated over a wide load-range from less than 10 to up to 200 % of nominal load, while maintaining adequate nitrogen conversions of at least 20 %. Even for drastic load changes, such as ramping the polytropic reactor from 10 to 200 % load in less than 20 min, fast, smooth, and stable transitions were observed (Figure 1, right).

Key Conclusions

The feasibility of load-flexible ammonia synthesis via polytropic fixed-bed reactors was demonstrated by detailed numerical simulation studies. The results show that the proposed reactor concept can be operated over a remarkably wide load-range and fast transient transitions are viable. In fact, these findings suggest that the operational load-range of an EDCR is predominantly constrained by economic considerations - specifically, the elevated construction costs of the EDCR design - rather than stability concerns. Additionally, polytropic reactor operation fully exploits the potential of a more active catalyst enhancing single-pass conversion significantly, particularly in comparison to state-of-the-art AQCRs.

References

[1] O. Elishav, B. M. Lis, E. M. Miller, D. J. Arent, A. Valera-Medina, A. G. Dana, G. E. Shter, G. S. Grader, 2020. Progress and Prospective of Nitrogen-Based Alternative Fuels. Chemical Reviews 120, 5352-5436.

[2] J. C. Morud, S. Skogestad, 1998. Analysis of Instability in an Industrial Ammonia Reactor. AIChE Journal 44 (4), 888-895.

[3] J. W. Rosbo, T. K. S. Ritschel, S. Hørsholt, J. K. Huusom, J. B. Jørgensen, 2023. Flexible Operation, Optimisation and Stabilising Control of a Quench Cooled Ammonia Reactor for Power-to-Ammonia. Computers & Chemical Engineering 176, 108316.

[4] L. Gottheil, J. Bremer, 2024. Enabling load-flexible ammonia synthesis via polytropic fixed-bed reactors. Computer Aided Chemical Engineering: 34th European Symposium on Computer Aided Process Engineering / 15th International Symposium on Process Systems Engineering, 1891-1896.

[5] J. Bremer, K. H. G. Rätze, K. Sundmacher, 2017. CO2 Methanation: Optimal Start-Up Control of a Fixed-Bed Reactor for Power-to-Gas Applications. AIChE Journal 63 (1), 23-31.

[6] D. C. Dyson, J.M. Simon 1968. Kineitc Expression with Diffusion Correction for Ammonia Synthesis on Industrial Catalyst. Industrial & Engineering Chemistry Researrch 7 (4), 605-610.

[7] T. Cholewa, B. Steinbach, C. Heim, F. Nestler, T. Nanba, R. Güttel, O. Salem, 2024. Reaction kinetics for ammonia synthesis using ruthenium and iron based catalysts under low temperature and pressure conditions. Sustainable Energy & Fules 8 (10) 45 (12), 4150-4155.

[8] L. Gottheil, J. Bremer, 2025. Advancing towards load-flexible ammonia synthesis via polytropic fixed-bed reactors. Submitted.

Figure 1: Left: Average cross-sectional N2 conversion as a function of central reactor temperature utilizing the magnetite-based catalyst (Femag) and the modern industrial iron catalyst (Feind) for AQCR and EDCR operation. Right: Dynamic simulations of a polytropic fixed-bed reactor (EDCR) subjected to changing GHSV using the industrial iron catalyst. The reactor is designed for a nominal GHSV of 7’500 h-1.