2025 AIChE Annual Meeting

(123a) Bayesian Copilot to Converge Process Simulations Via Open-Loop Surrogates

Data-driven solutions have been proposed to overcome the above-mentioned limitations, including using machine-learning models as process surrogates for prediction and optimization [7]. Process surrogates can vary greatly in terms of their surrogacy level, ranging from replacing entire systems to integrating hybrid models at the unit or property level [8]. The choice of surrogate model can also span from more interpretable ones (e.g., symbolic regression [9]) to more data-driven ones (e.g., Gaussian Processes [10] and artificial neural networks [11]). While hybrid models often achieve higher predictive accuracy for each surrogate individually, they are susceptible to error propagation [12]. Conversely, more complex surrogates can represent more intricate system behaviors but at the cost of reduced interpretability and increased data requirements [8]. Overall, surrogate models are more stable and easier to optimize compared to the original process simulation, yet guaranteeing accurate predictions and truly optimal solutions that are required for well-informed decision-making remains a significant challenge.

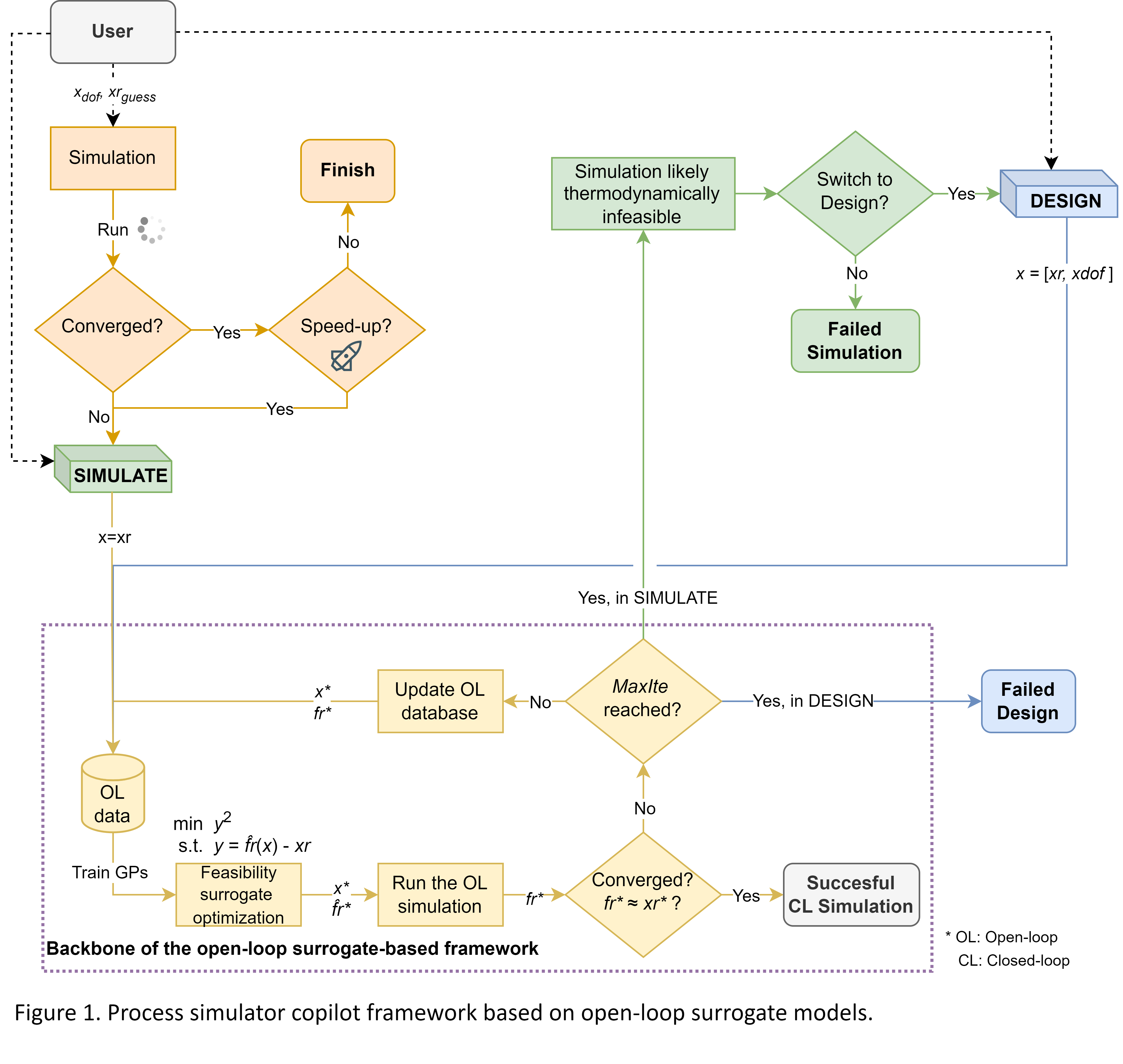

Here, we propose a process simulation copilot based on open-loop surrogate models to aid engineers in converging complex flowsheets where the simulators fail (Figure 1). Therefore, instead of traditionally using process surrogates for predictions, which are by definition always approximations of the underlying system, our approach replaces failure-prone iterative calculations within simulators. Open-loop surrogates model flowsheets with iterative calculations disabled, therefore mitigating computational inefficiencies and convergence issues. A feasibility optimization problem, in which the standard iterative convergence calculations are replaced by surrogate-based constraints, generates candidates that drive the simulation toward convergence in closed-loop (i.e., meeting design specifications and closing the recycle loop). Iteratively updating the open-loop surrogates with the new candidate in an adaptive sampling fashion allows this data-driven framework to resolve unconverged process simulation blocks. If no closed-loop solution is found within a predefined numerical tolerance, the algorithm deems the process flowsheet thermodynamically infeasible with some statistical confidence. In such cases, the algorithm can switch to the design mode, where process variables (i.e., flowsheet degrees of freedom) are allowed to change, such that the surrogate-based framework can identify a feasible, closed-loop simulation.

We validated the proposed process simulation copilot framework on a mathematical benchmark problem, as well as for a hard-to-converge recycle loop in a monoethanolamine (MEA) absorption cycle flowsheet and a distillation column for methanol-water separation with tight design specifications. Across all case studies, the adaptive sampling approach with open-loop surrogates successfully identified closed-loop solutions within fewer than ten iterations where the built-in Aspen Plus and HYSYS solvers were unable to converge the recycle or design specification from a generic starting point, requiring only a modest overhead of initial open-loop simulations (ca. 10 times the number of iterative variables). Furthermore, the framework reliably detected infeasible flowsheets and, in design mode, successfully adjusted process variables to achieve feasible operation. These results demonstrate that the proposed approach offers a robust and efficient alternative to conventional solvers built into process simulators, enhancing their performance in complex flowsheets. Our approach is particularly suited for cases where convergence stability is problematic or prior knowledge and initialization strategies are insufficient.