2025 AIChE Annual Meeting

(584cg) Batch to Continuous HTL: The Role of Temperature Profiles, Phase Heating, and Slurry Velocity in Biocrude and Char Formation

Authors

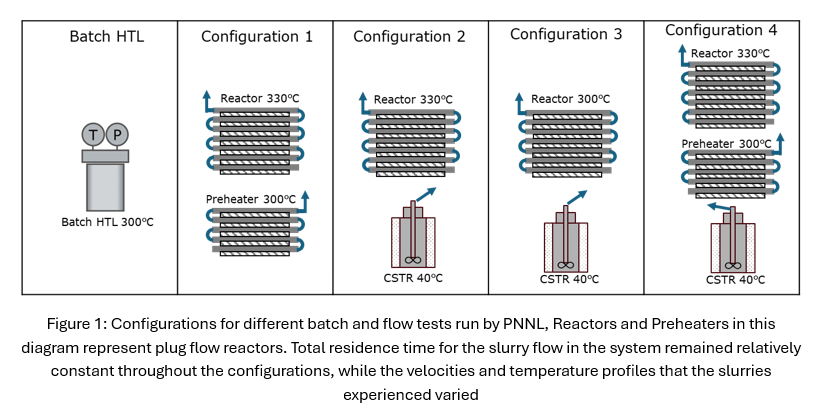

To understand the effects of changing temperature profiles, a case study was conducted on this topic which compared batch HTL temperature profiles to continuous ones. Temperature profiles as well as mixing conditions were altered to simulate the batch conditions more closely in the continuous system. To accomplish this, different components such as a preheater and a CSTR were incorporated into the system allowing for the feed to experience different temperature gradients. This analysis revealed strong connections between heating rates and reaction temperature and the product yields and will be crucial as the design process for continuous HTL reactors continues.

The effects of flowrate were also studied in the continuous system. A strong link was found between having lower flowrates and higher char yield. This connection was attributed to suspension stability where solid particulates fell out of the slurry causing more time to be spent at lower temperature ranges where repolymerization to char is more likely to occur.