2025 AIChE Annual Meeting

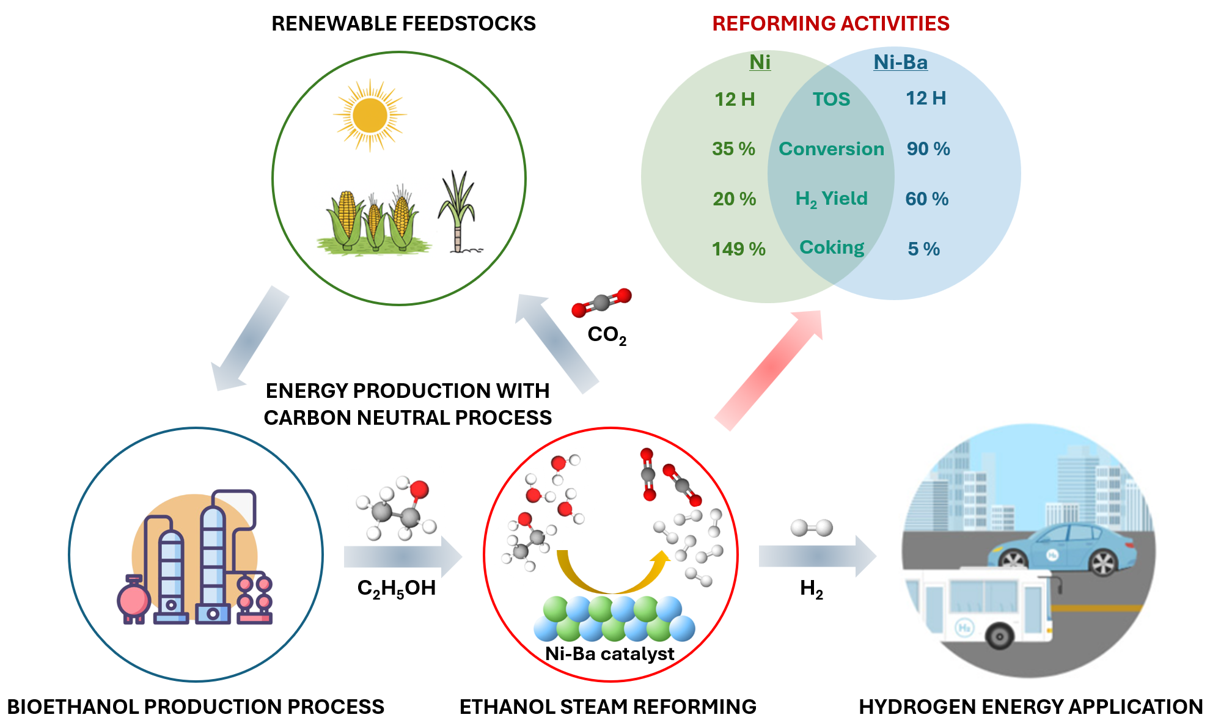

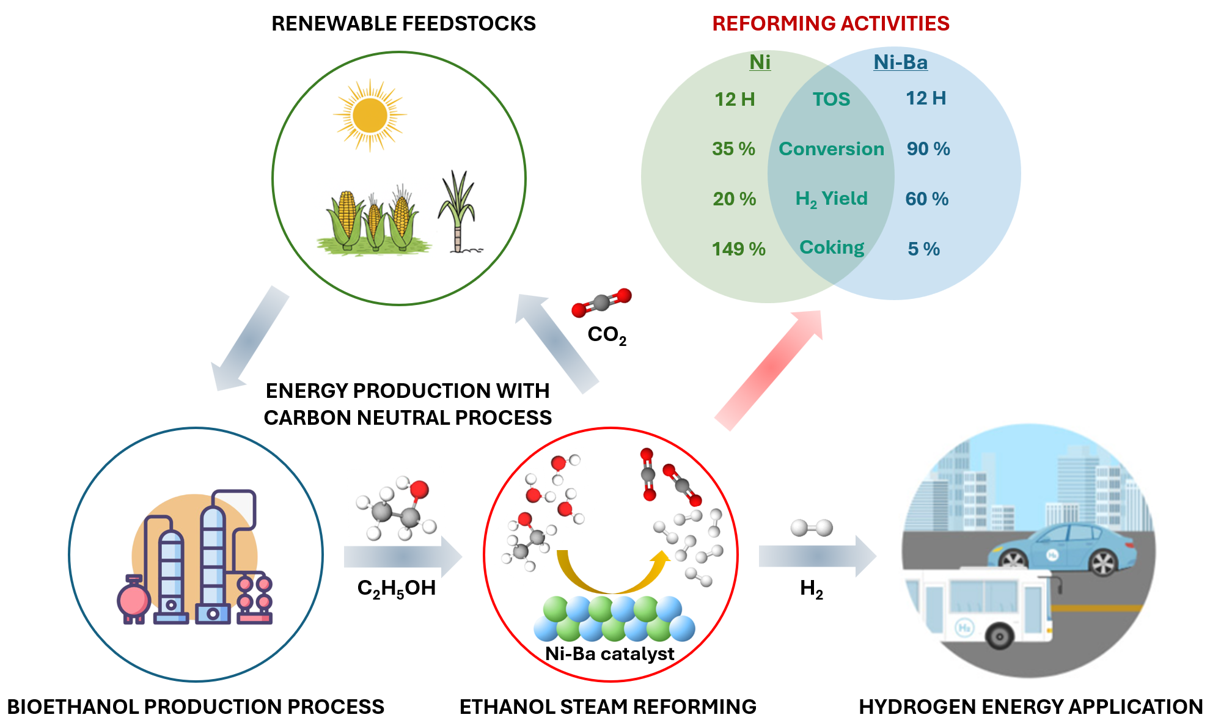

(251a) Barium-Promoted Nickel Catalyst with Enhanced Coking Resistance for Efficient Hydrogen Production Via Ethanol Steam Reforming

Authors

Jason Ingram, Washington State University

Marshall Douglas Buffett, Washinton State University (WSU)

AbdulJabbar MohammedHussain, Nissan Technical Centre North America

Nilesh Dale, Nissan Technical Center North America

Hydrogen (H2) energy stands as a cornerstone of decarbonization strategies, particularly for hard-to-abate sectors like H2-powered vehicles. However, challenges in storage, infrastructure, and production costs necessitate transitional solutions such as bioethanol-derived green H2. Central to this process is ethanol steam reforming (ESR), where nickel (Ni) catalysts are highly active, but face rapid deactivation from carbon deposition (coking) primarily driven by ethanol dehydration via ethylene polymerization. This study focuses on barium (Ba) as a promoter in Ni-based catalysts to address these limitations. While previous studies have explored Ba as a promoter to mitigate the limitation of Ni catalysts in ESR, the reported improvements in H2 production and catalyst stability remain inconsistent and insufficiently characterized. We hypothesize that the inherent characteristics of Ba provide a theoretical foundation for modulating the Lewis basicity of catalysts to favor dehydrogenation over dehydration, thus favoring acetaldehyde formation, which enhances H2 yield while suppressing coking. To isolate the effect of Ba on Ni catalysts we focused our investigation on unsupported catalysts. Monometallic Ni and bimetallic Ni-Ba (2:1 molar ratio) catalysts were synthesized via ball milling and thermal treatment, then tested in a continuous-flow fixed-bed reactor at 700 °C. Ni catalyst produced a 20% H2 yield and increased the mass of catalyst by 149 % carbon over 12 hours. In stark contrast, the Ni-Ba catalyst maintained a 60 % H₂ yield with 5 % in the mass of catalyst due to carbon deposition, demonstrating significantly enhanced stability. Temperature Programmed Surface Reaction experiment confirmed higher acetaldehyde and H2 production for the Ni-Ba catalyst compared to Ni catalyst, validating promotion of the dehydrogenation pathway by adding Ba and increasing the Lewis basicity. The Ni–Ba catalyst will be employed as an internal reforming layer in metal-supported solid oxide fuel cells. Its performance will be evaluated under direct ethanol feed conditions.