2025 AIChE Annual Meeting

(467a) Automation and Control of an Experimental Protonic Membrane Steam Methane Reforming System

Authors

Dominic Peters - Presenter, University of California, Los Angeles

Christopher G. Donahue, California State Polytechnic University, Pomona

Jake Stanely, University of California, Los Angeles

Carlos Morales-Guio, University of California, Los Angeles

Panagiotis Christofides, University of California, Los Angeles

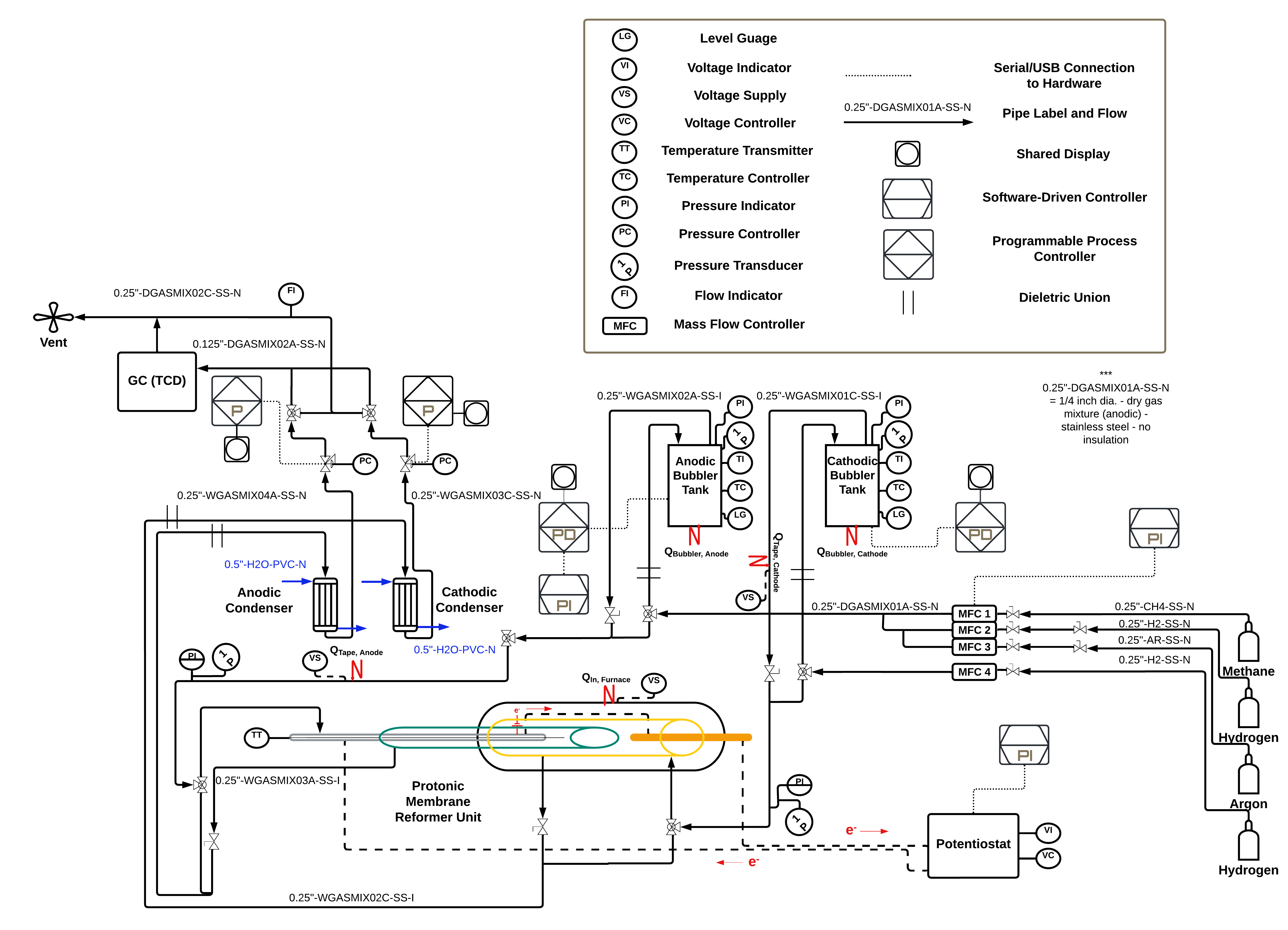

Automating protonic membrane reforming reactors is a major technical challenge that, if solved, can help to foster the commercialization of compact thermo-electrochemical hydrogen generators [1]. To that end, we developed the first multi-input multi-output control architecture for an experimental protonic membrane reforming system that lowered the operating temperature of the reformer unit to 788 °C. To design classical feedback loops for the process, a relative gain array of three key process variables [2] —the steam-to-carbon ratio of reactants, the overall hydrogen production rate, and the purification rate of the value-added hydrogen product —was developed to couple input-output variables and determine practical operating conditions for control experiments. Given the nonlinear dependence of steam methane reforming and water gas shift kinetics on thermodynamic conditions, all three feedback loops were experimentally tested for controller stability, operational safety, and disturbance rejection during multi-setpoint tracking. As designed, the control architecture properly shifted the kinetic equilibria of the reforming reactions by automatically calculating hydrogen separation rate setpoints, thereby removing hydrogen from the reaction zone and increasing the overall conversion of methane to 99.6%. Integrator windup scenarios and counterproductive control actions were also avoided through rational controller design and proper controller tuning exercises. Industrial-scale applications of protonic membrane reformers may therefore be automated to control up to three process variables and have up to three additional control degrees of freedom for process intensification and optimization, making for well-governed, autonomous hydrogen generation units.

[1] Fjeld, H.; Clark, D.; Yuste-Tirados, I.; Zanón, R.; Catalán Martínez, D.; Beeaff, D.; Hernández Morejudo, S.; Vestre, P.; Norby, T.; Haugsrud, R.; Serra, J.; Kjølseth, C. Nature Energy 2017, 2, 923–931.

[2] Cui, X.*; Peters, D.*; Wang, Y.; Çıtmacı, B.; Richard, D.; Morales-Guio, C. G.; Christofides, P. D. Chemical Engineering Research and Design 2024, 212, 493–519.