2025 AIChE Annual Meeting

(46h) An Artificial Intelligence (AI) Framework for Optimization of Operating Conditions and Geometry As Well As Material Screening for Membrane Gas Separation Applications

Authors

Mohammad Bazmi - Presenter, University of Southern California

Ken-ichi Nomura, Mork Family Department of Chemical Engineering and Materials Science, University of Southern California, Los Angeles, CA

Kristian Jessen, University of Southern California

Theodore Tsotsis, University of Southern California

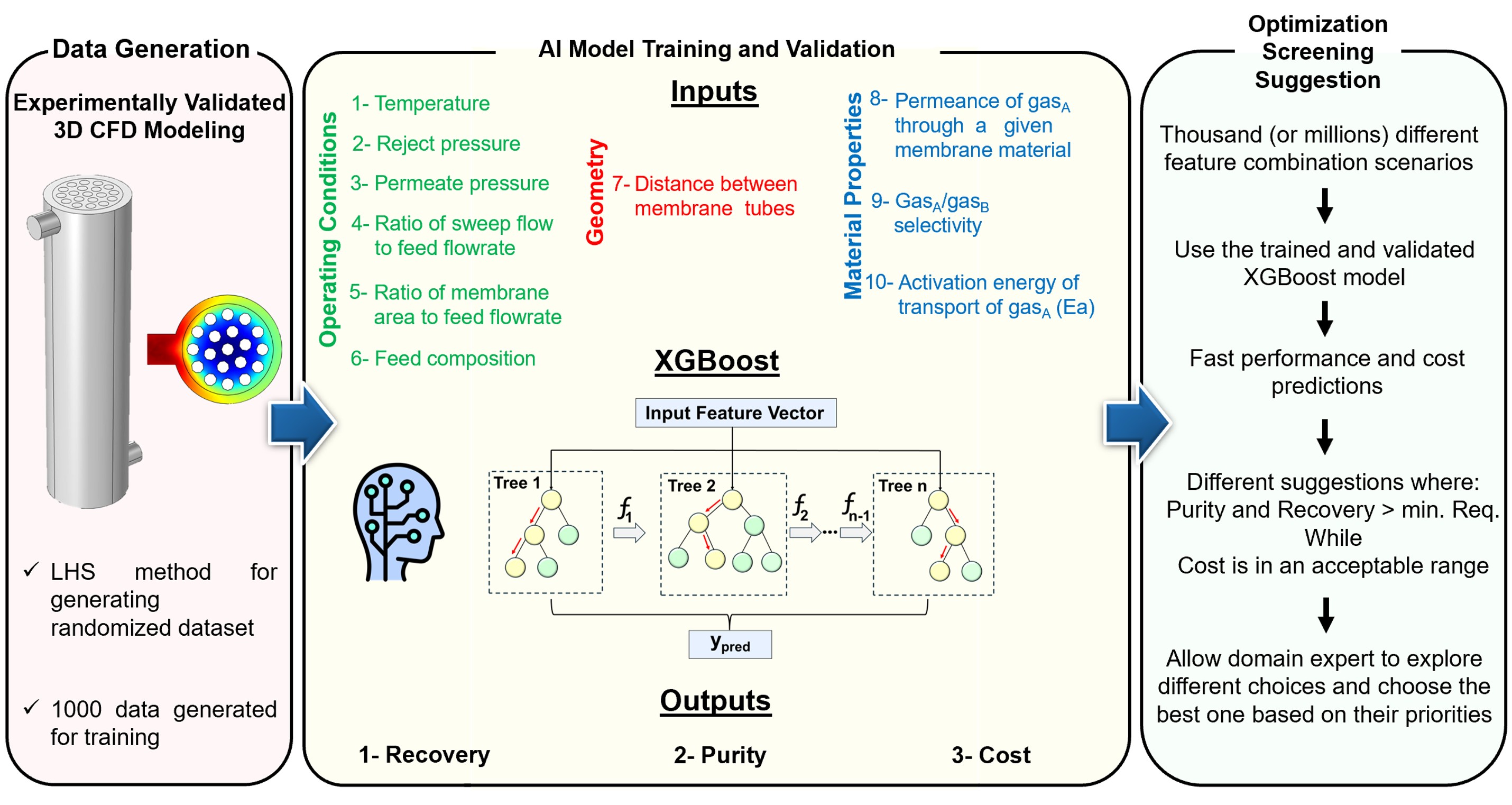

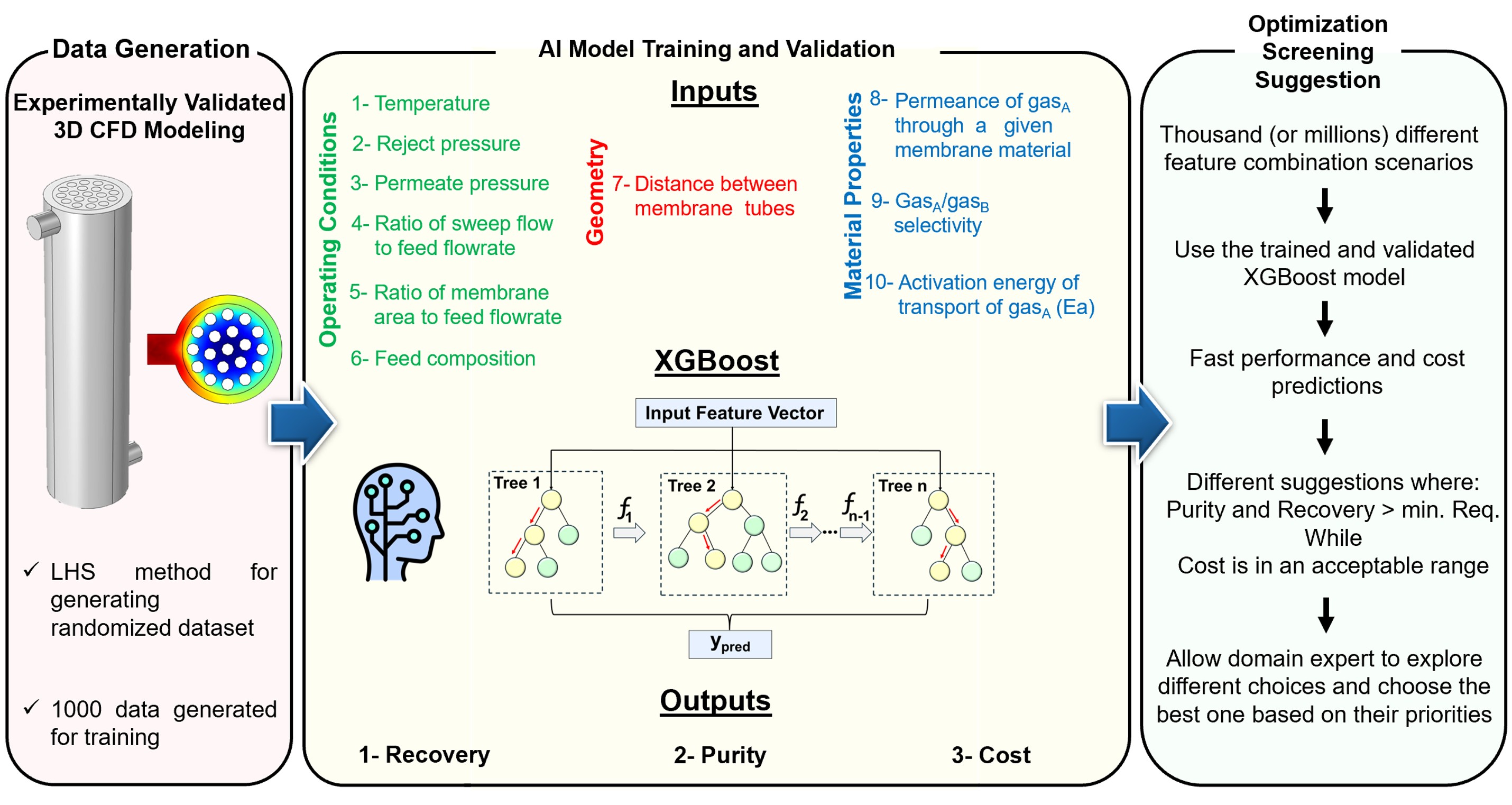

Artificial Intelligence (AI) has been gaining increasing attention in process engineering, revolutionizing the way complex systems are analyzed, optimized, and designed. One area where AI's potential could be particularly promising pertains to industrial-scale gas separation membrane systems, where performance prediction plays a critical role in system design and optimization. While advanced 3D models capable of capturing non-idealities in transport phenomena and complex, large-scale geometries have proven to be the most accurate method for predicting the performance of such systems, their high computational cost makes them impractical for process optimization and large-scale screening. In this study, we developed an AI-based model for the rapid and accurate prediction of tubular membrane gas separation system performance. The Extreme Gradient Boosting (XGBoost) algorithm was employed for model training and predictions. The model utilizes a comprehensive set of 10 input parameters spanning operating conditions, system geometry, and membrane material properties to predict three key output parameters: recovery, purity, and total cost. A relatively small computational effort is required to train the model, achieving an excellent average prediction accuracy ( RMSE = 3.4). To illustrate the application of the framework, the AI model is applied to a case study of H2/CO2 separation where the goal is to achieve a H2 purity and recovery of over 90% while minimizing the total cost. Unlike traditional optimization methods that typically converge to a single global (or local) minimum, this AI framework identifies multiple feasible combinations of input parameters, enabling efficient optimization of operating conditions and geometry, as well as membrane materials screening. This flexibility allows domain experts to explore various optimized scenarios and select the most suitable candidate based on their expertise, making the decision-making process more informed and adaptable to practical constraints.