2025 AIChE Annual Meeting

(170e) Advancing Microfluidic Design with 3D Printed on-Chip Flexible Valves

Authors

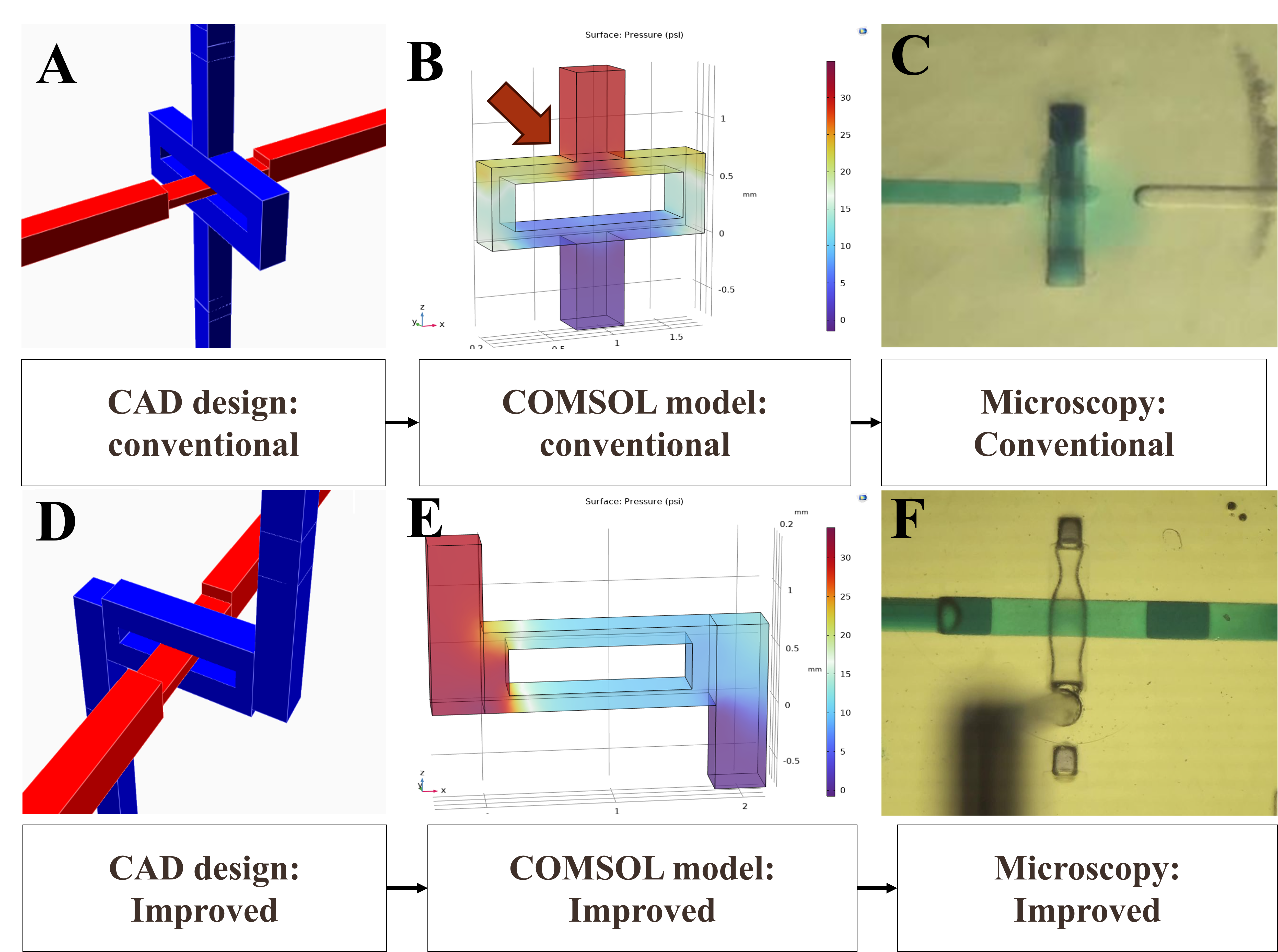

In this work, we address these fundamental challenges by developing and validating novel alternatives for vertically oriented valve architectures using digital light processing (DLP)-based stereolithography. Microfluidic devices were printed using a 385 nm Asiga Pro4K65 printer with silanized glass substrates for improved adhesion and optical clarity. Designs were generated in OpenSCAD/SolidWorks and optimized through parametric sweeps of membrane geometry and wall thickness. Processing-property relationships were established via COMSOL Multiphysics® simulations to evaluate flow fields, stress concentration, and valve deformation under pressure. To mitigate failure modes such as membrane tearing and asymmetrical loading, control inlets were repositioned and reinforced, and fabrication parameters were adjusted to enhance interlayer bonding and reduce void formation. Post-processing included vacuum extraction, resin IPA flushing, and UV curing under defined irradiance profiles to preserve membrane compliance.

Experimental testing confirmed reliable flow control up to 25 psi with no leakage or delamination. Compared to earlier designs, the optimized valves demonstrated enhanced mechanical robustness, sealing fidelity, and printing reproducibility. These results reveal key insights into the relationship between printing parameters and mechanical performance in soft structures, highlighting the importance of directional design and process tuning. Our approach introduces a viable pathway for integrating complex flow control directly into 3D printed microfluidic systems—without post-fabrication assembly—and provides a framework for extending this method to multilayer networks and functional materials. This work directly addresses key processing challenges in 3D printing, including interlayer adhesion, integrated membranes’ performance, and micro-feature fidelity, while enabling new capabilities for biomedical microfluidic applications. Future work will focus on integrating these optimized valves into multilayered microfluidic platforms with advanced 3D plumbing architectures to enable spatially precise chemical delivery, dynamic control of biological microenvironments, and expanded functionality for in vitro and in vivo biomedical applications.

Figure 1. Comparison between conventional and improved 3D-printed membrane valve designs for microfluidic applications. The work flow started from the designing in CAD, then to simulation in COMSOL, and finally 3D printed and tested. (A–C) The conventional valve design exhibits inefficient actuation due to misaligned geometry and nonuniform pressure distribution. (D–F) The improved valve design incorporates strategic geometric modifications to enhance mechanical compliance and interlayer sealing, leading to more effective actuation under the same pressure.