2025 AIChE Annual Meeting

(435a) Advanced Mixing Solutions for Aerated Fermenters and Biotechnological Processes

Authors

Key mixing tasks in fermentation include oxygen transfer, heat removal, suspension of solids, and homogenization of nutrients and pH reagents. EKATO addresses these with tailored impeller technologies such as the PHASEJET for primary dispersion and COMBIJET for redispersion and bulk flow, offering significant advantages over traditional Rushton turbines, especially in high gas flow conditions. Notably, other mixing systems e.g. based on the the IMIG-X impeller are engineered for higher viscous, shear-thinning systems like Xanthan Gum fermentations.

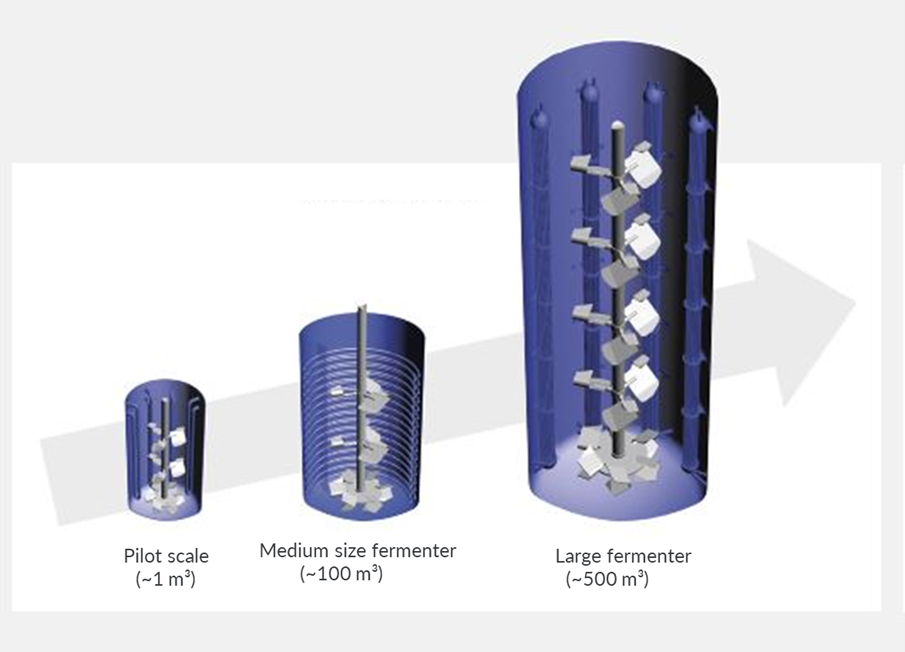

EKATO's design philosophy emphasizes scale-up fidelity (maintaining constant OTR and volumetric gas flow rates), heat transfer efficiency, and mechanical reliability under sterile and high-volume conditions. Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) tools play a critical role in evaluating stress behavior and flow dynamics in large fermenters. This ensures structural integrity and performance from lab-scale to production scale.

Recently, there is growing interest in gas fermentation processes, particularly for energy storage and protein production. Sparged and stirred fermenters have proven especially suitable for these applications. While design and scale-up can benefit from EKATO’s experience with aerobic fermentations and gas-phase reactions such as hydrogenations, gas fermentations also present distinct challenges in process requirements and reactor design compared to conventional aerobic systems.

EKATO offers a full range of services including revamping, optimization, and new fermenter design. Innovations like the “Single Feed Pipe” concept further enhance operational robustness by reducing sparger blockage risks.

Backed by an interdisciplinary team of over 20 engineers and scientists, EKATO provides integrated solutions that ensure high mixing performance, reduced energy consumption, and process reliability tailored to the demands of modern industrial fermentation.