2025 AIChE Annual Meeting

(587i) Advanced Chemical Looping Gasification of Biomass for High-Purity Syngas Production with Inherent CO2 Capture: A Pathway to Sustainable Liquid Fuels

Authors

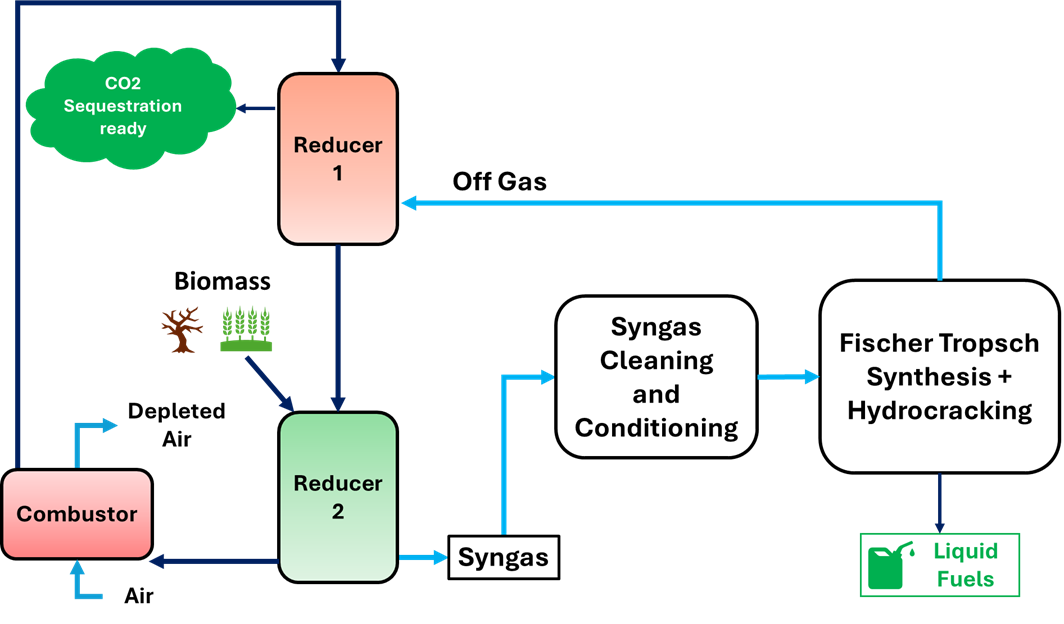

This work presents a chemical looping gasification process designed to maximize high-quality syngas production from biomass while efficiently utilizing residual off-gases from Fischer-Tropsch (FT) synthesis. The system operates through three interconnected reactors, In Reactor 1, FT off-gases react with metal oxide-based oxygen carriers in a moving bed reactor producing a sequestration-ready CO₂ stream (~99% purity). In Reactor 2 (gasifier/reducer), biomass reacts with the partially reduced oxygen carriers, generating high-purity syngas (~87%) with an H2/CO ratio (~1.1) for FT synthesis. Finally, in Reactor 3 (combustor), the oxygen-depleted oxygen carriers are regenerated in a fluidized bed, supplying the heat needed for gasification before recirculating to Reactor 1. This process is based on the Ohio State University’s moving bed chemical looping process known for its biomass to syngas conversion technology.

To assess its potential and performance, the process was evaluated through comprehensive modeling, experimental validation, and economic analysis. ASPEN Plus simulations were conducted to analyze key operating parameters namely temperature, pressure, solid circulation rates, and feedstock composition optimizing reactor performance and maximizing liquid fuel yield predictions. These results were validated through practical demonstration in a 2.5 kWth integrated moving bed reactor, confirming stable operation, efficient heat integration, and targeted syngas compositions. Additionally, a techno-economic analysis was performed, including conceptual process flow development, CAPEX/OPEX estimation, and a comparative assessment against conventional biomass-to-liquids pathways, ultimately determining a competitive minimum fuel selling price.

This integrated chemical looping configuration offers significant economic and process intensification advantages over traditional biomass-to-liquids pathways. A key benefit is the inherent CO2 capture, producing a high-purity stream ready for sequestration or direct use without energy-intensive amine scrubbing. Additionally, the process generates high-quality syngas within the gasifier, eliminating the need for costly ancillary units such as an Air Separation Unit, a dedicated tar reformer, and amine-based acid gas removal systems reducing capital costs, energy consumption, and operational complexities.

Taken together, these compelling technical and economic merits, substantiated by the multi-scale assessment encompassing simulation, bench-scale experimentation, and economic modeling, position this novel chemical looping process as a highly promising technology. It offers an efficient, cost-effective, and environmentally advantageous pathway for producing sustainable transportation fuels from diverse biomass resources, thereby contributing positively and substantially to achieving future energy security and critical climate mitigation goals.