2025 AIChE Annual Meeting

(563f) Adsorptive Separation of Gases Via Series-Parallel Split-Bed Configuration

Authors

INTRODUCTION

Adsorptive gas separation is carried out in a variety of column configurations, namely, fixed packed bed, true and simulated moving beds, rotary bed, and fluidized bed. The fixed packed bed column is the most common of all the configurations. Its simple design allows for ease of operation and maintenance, while its scalability and versatility makes it suitable for various processes. Additionally, it can offer near plug-flow of gases ensuring uniform residence time [1]. However, its energy consumption is high due to the relatively large pressure drop across the bed. The high pressure drop limits feed flow rate and process productivity. The pressure drop can be reduced by using adsorbents with large particle size, but this results in low recovery because of low surface-area-to-volume ratio and cause high dispersion of the mass and heat transfer zones. Another alternative is to use structured packings such as monoliths and laminates. But different structured sorbents tested thus far have failed to considerably reduce the footprint due to low effective sorbent loading [1]. They are also typically more expensive. A wide packed bed with a short height can also be used to reduce pressure drop. However, ensuring uniform gas distribution in this configuration is challenging.

This paper presents a packed bed configuration designed to reduce pressure drop, thereby minimizing the energy consumption of blowers and vacuum pumps in packed bed operations. The pressure drop in a fixed bed increases with column length and velocity of the fluid. Therefore, shortening the packed bed height or reducing the velocity can reduce the pressure drop, thereby lowering the energy requirements. To facilitate this, a split-bed configuration is proposed in which a packed bed is split into multiple smaller beds using controllable partitions with each section having its own inlet and outlet that may be operated to provide series or parallel gas flow configuration as necessary [2]. The feed to individual beds can be divided based on the split-bed capacity. Splitting the feed reduces gas velocity and pressure drop, thus lowering energy consumption without compromising—and potentially improving—KPIs like purity, recovery, and productivity. The column's flexibility to operate in series or parallel is best utilized when different steps of a cyclical process use each mode as per the requirements. For example, adsorbing a target gas from a gaseous mixture is probably done best in series mode as the gas travels through the entire column, while the bed regeneration using depressurization can be executed more effectively in parallel by independently depressurizing the plurality of split beds.

SPLIT-BED CONFIGURATION

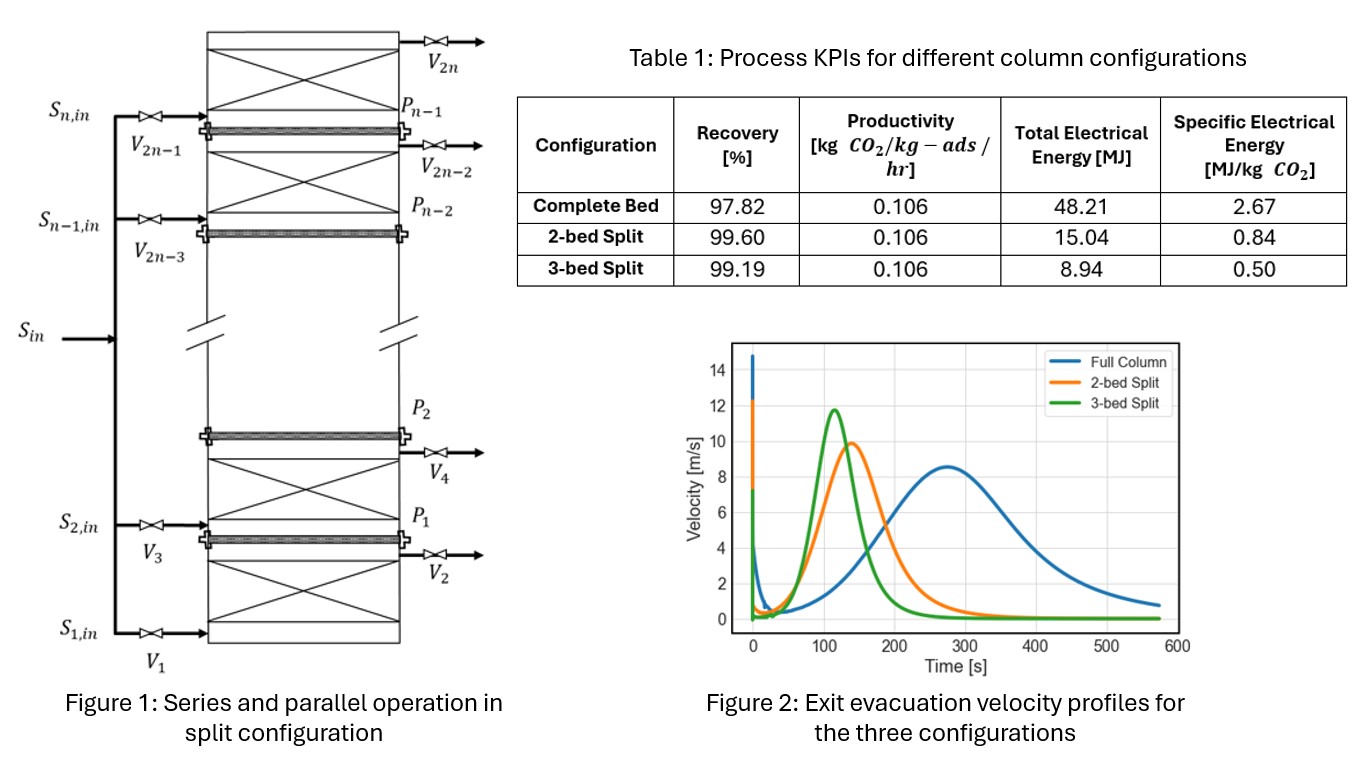

Fig. 1 shows a schematic diagram of a split bed configuration in which n number of beds of the same cross-sectional area, but not necessarily the same height, are formed by using n-1 partitions P1, P2 ..., Pn-1. The valves V1, V2 ..., V2n-1, Vn allow entry and exit of the gaseous stream into and out of the packed beds, thus facilitating independent control of each bed in the column. The number of valves may increase depending on the process complexity and the number of process streams that need to be connected to each section. For example, additional valves may be required for further operations on the beds such as forward and reverse evacuation. Since beds with more packing material can process more feed, the feed Sin to the column is split into n different feeds S1,in, S2,in ..., Sn-1,in, Sn,in to each bed depending on the height of each bed or the amount and type of sorbent in each bed. When all the partitions are shut and all the feed and/or product valves are open, the n split beds operate in parallel, thereby operating independently. On the other hand, when all the partitions are opened and all the valves except the entry valve V1 of the first bed and the exit valve V2n of the last bed are closed, the beds operate in series, like a single packed bed column.

METHODOLOGY

Carbon capture via a novel vacuum-temperature-concentration swing adsorption (VTCSA) [3] was simulated to demonstrate the efficacy of the proposed split-bed configuration. A 2 m long column with a 0.196 m2 cross-sectional area, containing 255.25 kg sorbent [4], was first fed with flue gas at 30 °C, containing 14% CO2 and balance N2 at a flow rate of 0.15 kg/s for 600 s. Next, pure CO2 at 300 °C was introduced for 600 s to uniformly raise the temperature of the packed bed. The bed released some of the adsorbed CO2 in this step, reducing the desorption load during the evacuation step. Afterwards the column was held under vacuum at 0.01 bar for 574 s to collect remaining CO2. This was followed by a 26 s pressurization step with ambient air containing 78% N2 and balance O2. Finally, the column was cooled for 600 s by passing ambient air at 30 °C to return the bed to nearly empty state. To compare the process KPIs, the VTCSA process was simulated with two-bed and three-bed split configurations of equal height partitions. While adsorption was operated in a sequential manner, all the subsequent steps were operated in parallel mode, with heating, pressurization and cooling divided equally among the split beds. The beds were parallelly evacuated from the product end during evacuation.

Adsorptive gas separation was modelled using the FVM methodology described in Haghpanah et al. [5]. The Ergun equation was employed to model the pressure drop. Given the wide range of temperature variations in the process, gas specific heat capacities are considered to vary with temperature, and the solid and gas phase temperatures are tracked independently. The complete simulation model, including the energy balance equations, is detailed in Badhan et al. [6].

It is acknowledged that the capital expenditure for the modified column design with controllable partitions and additional control valves will be higher. The overall cost-benefit analysis should be performed before choosing the number of desired partitions.

RESULTS & DISCUSSION

Tabel 1 compares the KPIs of the two proposed configurations with those of the original packed bed column. It is clear from the table that total and specific energy decrease with the increasing number of splits in the bed, while recovery and productivity remain approximately the same. The specific electrical energy consumption decreased by 68.54% and 81.27%, respectively, for the 2-bed and the 3-bed split configurations compared to the conventional single bed case. Additionally, the evacuation energy is same across the three bed configurations since the amount of CO2 evacuated is similar for the three cases. It is clear from the exit velocity profiles for the three configurations shown in Fig. 2 that shorter beds can be evacuated faster. Hence, the cycle time for evacuating the shorter beds can be further reduced without compromising on product recovery.

The split-bed configuration for gas separation via adsorption is suitable for different types of regeneration techniques such as VSA, TSA, CSA or combinations of these techniques. It is prudent to evacuate the more saturated split-bed from the feed end and the less saturated split-bed from the product end; this process can be easily implemented by operating the split beds in paralled. Moreover, since the target gas concentration in the sorbent decreases in the direction of gas flow, the loading towards the exit is low, resulting in underutilized bed. Hence, to ensure efficient utilization of the split-beds, the adsorption feed direction to the split beds can be changed for alternate cycles. Furthermore, a suitable combination of different sorbents, depending on their working capacities for the given operating parameters, can be packed together in the complete column to optimize the sequential adsorption step. Additionally, the split-bed configuration, connected in a closed loop, can be used to realize a simulated moving bed process by suitable switching of valves.

SUMMARY

The fixed packed bed column exhibits a significant pressure drop, leading to high electrical energy consumption even at moderate gas velocities. A split-bed configuration with multiple controllable partitions proposed here enables both series and parallel gas processing in the beds. Parallel mode operation of process steps—such as direct heating, direct cooling, and evacuation—reduces energy consumption by lowering flow rates and shortening bed height. Simulation results show that 2-bed and 3-bed split columns lower the by 69% and 81%, respectively, compared to the conventional fixed bed column used for carbon capture via the VTCSA process. This energy reduction is achieved while maintaining comparable KPIs, such as recovery and productivity, leading to significantly lower operating costs.

REFERENCES

Chaitanya Dhoke, Abdelghafour Zaabout, Schalk Cloete, and Shahriar Amini, Review on Reactor Configurations for Adsorption-Based CO2 Capture, Industrial & Engineering Chemistry Research 2021

Split Bed Packed Column for Processing Gas And Method Thereof, IPO Application Number: 202421071993

Method and System for Gas Separation in Fixed Beds, IPO Application Number: 202421071987

Surajit Sengupta, Satyanarayana Akuri Reddy, Rajeshwer Dongara, Asit Kumar Das, Haripada Bhunia, and Pramod Kumar Bajpai, Improvement in Regeneration Properties and Multicycle Stability for K2CO3/Al2O3 Adsorbents for CO2 Removal from Flue Gas, Energy & Fuels 2014

R. Haghpanah, A. Majumder, R. Nilam, A. Rajendran, S. Farooq, I. Karimi and M. Amanullah, Multiobjective Optimization of a Four-Step Adsorption Process for Post Combustion CO2 Capture via Finite Volume Method, Industrial and Engineering Chemistry Research, pp. 4249-4265, 2013

Badhan, N.S., Suhail, M., Chaudhary, A., Subramanian, S., Runkana, V., and Rao, D.P., Unified Model for Fixed-bed Adsorption Gas Separation Processes, in preparation