2025 AIChE Annual Meeting

(625e) Adsorption-Based Carbon Capture from Mobile Sources with Direct-Contact Heat Transfer: A Simulation Study

Authors

Introduction

The urgent need to abate global warming has prompted extensive research into carbon capture technologies for large point emitters. Mobile sources, including maritime and road transport, present unique challenges for CO₂ capture such as space limitations, weight constraints, and dynamic engine load conditions. For maritime capture some researchers have explored the utilization of amine scrubbing systems [1], for road transport vehicles (Class 8 trucks) adsorption-based solutions are attractive due to their compact design and energy efficiency. Absorption based technologies have reported recoveries up to 90%, while adsorption-based solutions exhibit recovery ranging from 11% to 80% for internal combustion engine vehicles [2]. Remora reported that their adsorption-based process could capture 80% of CO₂ emissions from truck exhaust [3]. Researchers have been pursuing newer adsorption-based capture systems to lower the specific electrical and/or thermal energy, and footprint of the units [4]. This work introduces a novel adsorption-based process exploiting the Thermal, Vacuum and Concentration swings for regeneration, thus abbreviated as TVCSA process [5]. The efficacy of the process is validated through simulations of a system designed to capture CO₂ from a typical truck exhaust. We compare its performance to a Vacuum Swing Adsorption (VSA) process with five steps.

Methodology

Packed beds of height 0.25m and diameter 0.91m containing nearly 90 kg of Zeolite 13X [7] are considered. The VSA process used two such beds while the TVCSA process employed four of these beds. The process is simulated with a feed gas at a flow rate of 0.12 kg/s containing 14 volume percent CO₂ (rest N2). In the TVCSA, feed temperature is varied from 30°C to 60°C. The process performances are compared on Key Performance Indicators (KPI) like Specific Electrical Energy (SEE), CO₂ recovery, purity, and productivity [8].

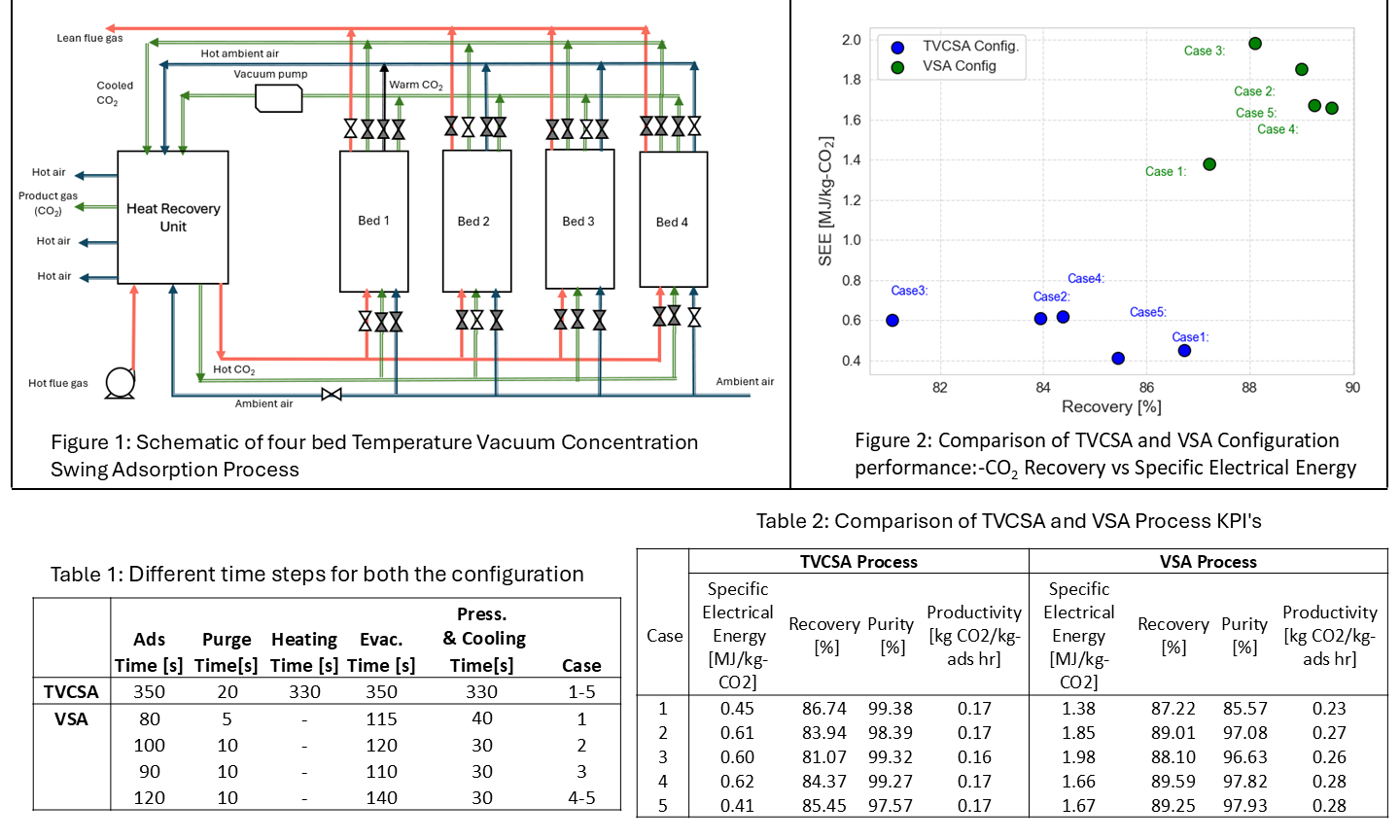

The four-step TVCSA process configuration is shown in Figure 1. The process steps and explored step timings for both the configurations are given in Table 1.

The TVCSA process followed six steps listed below:

- Adsorption: Fresh feed at a controlled temperature (30°C to 60°C) is fed to the column.

- Purging with product CO₂: The bed is purged with hot CO₂ to displace nitrogen (N₂) from the solid to enhance the product purity. The gas from the column is rejected.

- Heating with product CO₂: The bed is heated by direct contact using hot product CO₂ (around 200-300°C) to remove a part the adsorbed CO2 .

- Evacuation: The bed is evacuated to a low pressure, desorbing more CO₂.

- Pressurization: The bed is pressurized with air to prepare it for cooling step.

- Cooling: The bed is cooled using ambient air for regeneration of the bed next cycle. The use of air provides the concentration swing to fully regenerate the bed.

The effectiveness of the process lies in the direct heat transfer employed in the heating and the cooling steps. The CO2 (product) is recirculated to heat the bed directly. Similarly, in the cooling step, ambient air is used to directly cool the bed. It is worth noting that the processes are designed with an objective of sourcing the heat duty fully from the hot engine exhaust. The hot air leaving the cooling step and the hot feed gas entering the system are used to heat the recirculating CO2 to the desired or maximum temperature (used as feed for Step 2 and 3) using two plate heat exchangers (PHE). The feed gas is further cooled to the desired feed temperature with ambient air in another PHE.

The VSA configuration required only two heat exchangers, one for cooling the flue gas and the second for heating the purge gas. The process is very similar to the TVCSA process except that it does not employ the heating step, further the step times are shorter as shown in Table 1. Unlike the TVCSA process, the VSA process entirely depends on evacuation step to collect the product.

A one-dimensional model was developed to simulate the performance of adsorptive carbon capture systems [6]. Cyclical steady state (CSS) simulations are performed. The solution is deemed to have converged to the CSS if the bed conditions profiles (bed adsorbate concentration and bed temperature) after successive cycles are close to one another within a tolerance (~1e-3).

Results and Discussion

In the TVCSA, several parameters are varied to understand the process behavior. These include: feed temperature (30°C-60°C), purging and heating CO₂ stream temperature (270°C-290°C), heating CO₂ flow rate (0.4-0.45 kg/sec), and cooling air flow rate (0.4-0.53 kg/sec). The feed stream temperature is tuned to improve recovery while heating and cooling step temperatures and flow rates impacted specific electrical energy and recovery more. Purging conditions are selected to meet the purity demands.

In the VSA, purging is performed at varying temperatures (180°C-220°C) at different flow rates (0.2 kg/s-0.3 kg/s), along with different step time for each process: adsorption (80s-120s), purging (5s-10s), evacuation (110s-140s), pressurization, and cooling together (30s-40s). While the purging step parameters were adjusted to enhance purity, the step times for other processes are varied to improve recovery and reduce specific electrical energy.

The simulation results demonstrate that CO₂ recoveries up to 87%, can be achieved using the TVCSA configuration. This is comparable to conventional adsorption systems for carbon capture. By utilizing sensible heat of flue gas and optimizing the step durations, it is possible to consistently obtain high CO₂ recovery across a range of operational parameters, as depicted in Figure 1(a). The Case-4 of VSA process achieved higher recovery. However, the TVCSA configuration (Case-1) reported an attractive SEE of 0.45 MJ/kg-CO2 demonstrating a significant reduction in specific energy consumption, compared to the VSA system (Case-2) as shown in Table 2. The two-step regeneration of heating and evacuation effectively reduced the load during the evacuation step, thereby enhancing overall the SEE. Although the VSA configuration is more compact with a faster cycle, it requires higher specific energy for achieving comparable CO₂ recovery and purity.

The TVCSA configuration requires longer step times, primarily to achieve uniform heating of the bed for better regeneration. This is the reason for its comparatively lower productivity shown in Table 2. Despite this, both configurations consistently achieved CO₂ purity levels exceeding 95% in most instances. There is a trade-off between CAPEX (VSA better) and OPEX (TVCSA better).

Summary

The TVCSA process demonstrated excellent specific electrical energy, perhaps the best reported so far in open literature, achieving recoveries up to 87%, making it highly competitive. Its integrated heat recovery system, selected step times, and short bed designs contributed to superior performance even when compared to a well-tuned VSA process. While the TVCSA configuration experiences longer cycle times and reduced productivity compared to VSA systems, it maintains high CO₂ purity (above 95%) and offers a more energy-efficient alternative without compromising performance. Experimental validation of the process is being planned.

References

- Feenstra, Maartje, Juliana Monteiro, Joan T. van den Akker, Mohammad RM Abu-Zahra, Erwin Gilling, and Earl Goetheer. "Ship-based carbon capture onboard of diesel or LNG-fuelled ships." International Journal of Greenhouse Gas Control (2019): 1-10.

- García-Mariaca, Alexander, and Eva Llera-Sastresa. "Review on carbon capture in ICE driven transport." Energies ((2021)): 6865.

- Carbon Capture for Semi Trucks. September 2024. 23 August 2023. <https://remoracarbon.com/>.

- Jiang, Nan, Yuanhui Shen, Bing Liu, Donghui Zhang, Zhongli Tang, Guobing Li, and Bo Fu. "CO2 capture from dry flue gas by means of VPSA, TSA and TVSA." Journal of CO2 Utilization (2020): 153-168.

- Mohammed Suhail, Ayush Chaudhary, Navneet Singh Badhan, Sivakumar Subramanian, Venkataramana Runkana, Davuluri Prahlada Rao. METHOD AND SYSTEM FOR GAS SEPARATION IN FIXED BEDS. INDIA: Patent IPO-202421071987. 2024.

- Navneet Singh Badhan, Mohammed Suhail, Ayush Chaudhary, Sivakumar Subramanian, Venkataramana Runkana, Davuluri Prahlada Rao. "Unified Model for Fixed-bed Adsorptive Gas Separation Processes." Under Preparation (n.d.)

- Marx, Dorian, Lisa Joss, Max Hefti, and Marco Mazzotti. "Temperature swing adsorption for postcombustion CO2 capture: single-and multicolumn experiments and simulations." Industrial & Engineering Chemistry Research 55 (2016): 1401-1412.

- Haghpanah, R., Majumder, A., Nilam, R., Rajendran, A., Farooq, S., Karimi, I. A., & Amanullah, M. " Multiobjective optimization of a four-step adsorption process for postcombustion CO2 capture via finite volume simulation. ." Industrial & Engineering Chemistry Research ((2013)): 52(11), 4249-4265..