2025 AIChE Annual Meeting

(392aq) Active Learning-Based Optimal Experimental Design of Non-Flammable Electrolytes for Durable Li-Ion Batteries

Authors

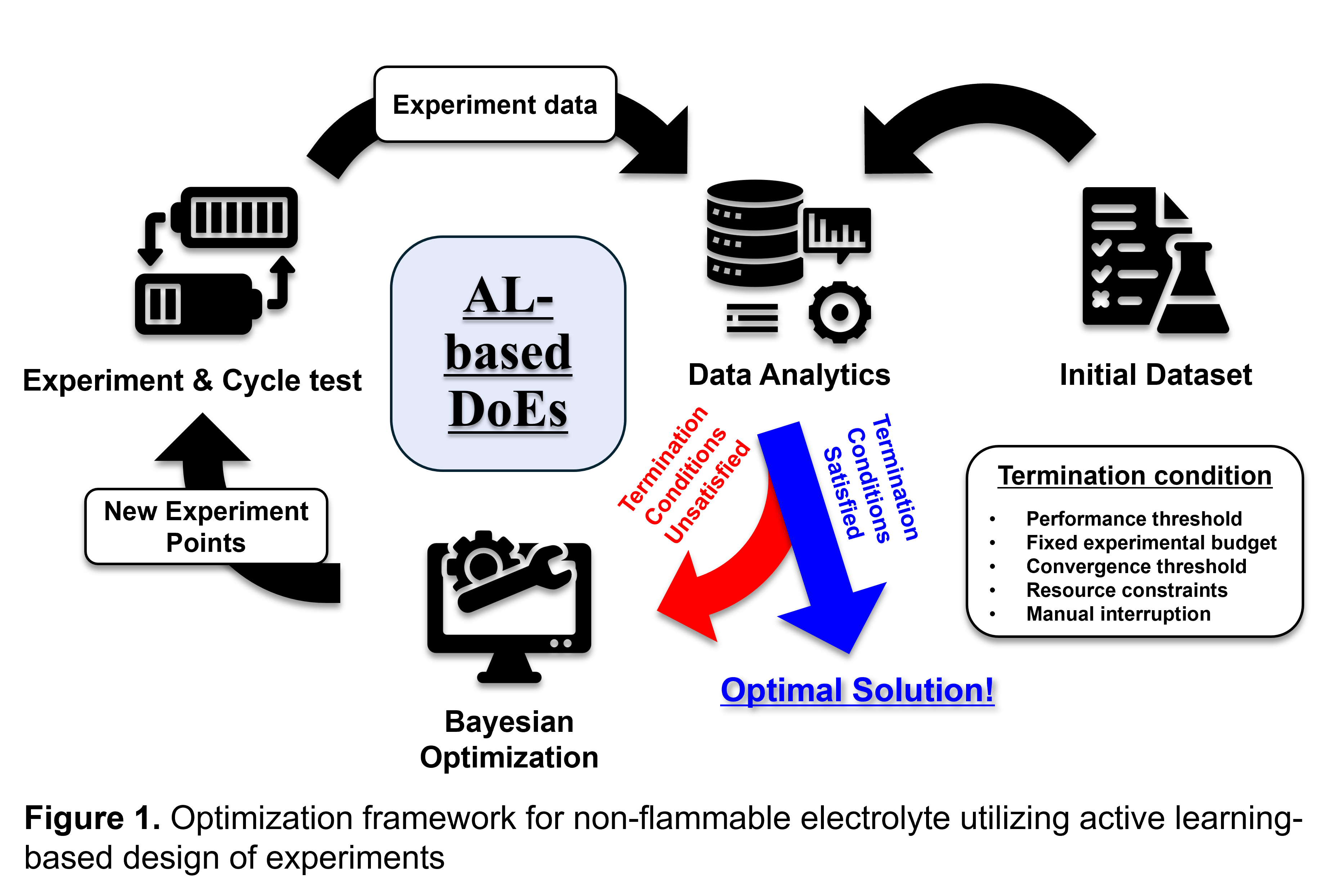

To address these challenges, we employ multi-objective constrained batch Bayesian optimization (MCB-BO) to develop an active learning-driven design of experiments (DoEs). This approach efficiently optimizes a non-flammable electrolyte with superior durability for LIBs. In addition, we suggest new metrics (involved in the objective function) to predict the long-term cyclability that requires only the early cycle data. This approach facilitates the efficient planning of the experiments, minimizing the number of required trials through a probabilistic framework to achieve high battery performance while ensuring non-flammability. Applying this methodology to electrolyte development, we demonstrate that our approach efficiently identifies optimal compositions with minimal experimental data. Furthermore, the developed electrolyte exhibits exceptional long-term performance in LIBs while adhering to safety constraints, highlighting its practical applicability beyond the experimental design strategy itself.

References

[1] Yuan, K., Lin, Y., Li, X., Ding, Y., Yu, P., Peng, J., Wang, J., Liu, H., & Dou, S. (2024). High‐Safety anode materials for advanced Lithium‐Ion batteries. Energy & Environment Materials, 7(5). https://doi.org/10.1002/eem2.12759

[2] Sun, Y. (2020). Promising All-Solid-State batteries for future electric vehicles. ACS Energy Letters, 5(10), 3221–3223. https://doi.org/10.1021/acsenergylett.0c01977

[3] Hemavathi, S., Srirama, S., & Prakash, A. S. (2023). Present and Future generation of Secondary Batteries: A review. ChemBioEng Reviews, 10(6), 1123–1145. https://doi.org/10.1002/cben.202200040

[4] Li, Y. (2024). Safety hazards and solutions of lithium-ion batteries. Highlights in Science Engineering and Technology, 121, 158–163. https://doi.org/10.54097/app0nv17

[5] Dave, A., Mitchell, J., Kandasamy, K., Wang, H., Burke, S., Paria, B., Póczos, B., Whitacre, J., & Viswanathan, V. (2020). Autonomous Discovery of Battery Electrolytes with Robotic Experimentation and Machine Learning. Cell Reports Physical Science, 1(12), 100264. https://doi.org/10.1016/j.xcrp.2020.100264

[6] Folch, J. P., Lee, R. M., Shafei, B., Walz, D., Tsay, C., Van Der Wilk, M., & Misener, R. (2023). Combining multi-fidelity modelling and asynchronous batch Bayesian Optimization. Computers & Chemical Engineering, 172, 108194. https://doi.org/10.1016/j.compchemeng.2023.108194

[7] Noh, J., Doan, H. A., Job, H., Robertson, L. A., Zhang, L., Assary, R. S., Mueller, K., Murugesan, V., & Liang, Y. (2024). An integrated high-throughput robotic platform and active learning approach for accelerated discovery of optimal electrolyte formulations. Nature Communications, 15(1). https://doi.org/10.1038/s41467-024-47070-5