2025 AIChE Annual Meeting

(91f) 3D Models, 1D Models and Flowsheet Modelling – How to Bring Loose Ends Together

Authors

In CFD, multi-scale modelling connecting the meso-scale (featuring flow patterns that directly determine the behaviour of the piece of equipment under consideration) to the micro-scale (featuring flow patterns or other thermal, chemical or phase change phenomena that determine the dynamics of the meso-scale) have been developed. As one example, filtered drag laws have become a standard in the Eulerian-Eulerian modelling of fluidized bed processes.

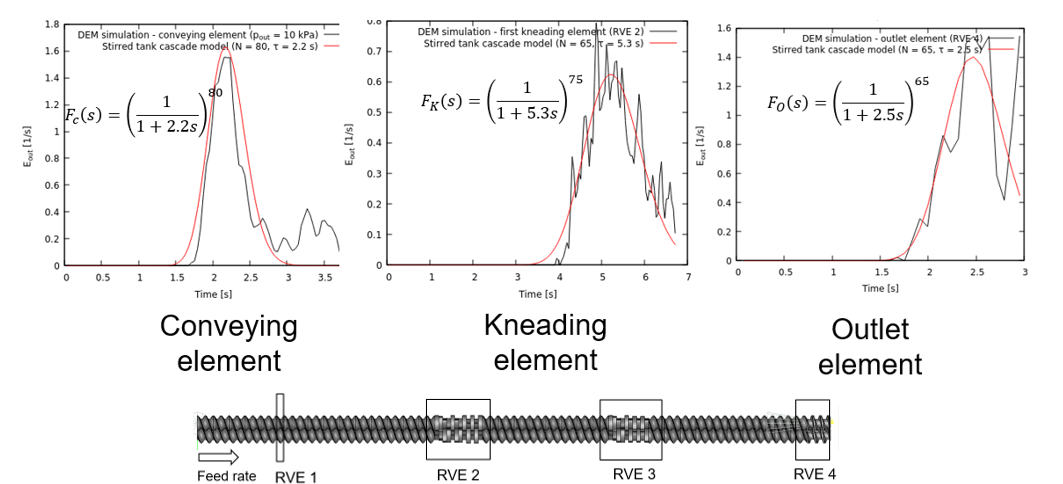

CFD or DEM models can also be used in tandem (online coupling) with a 1D model. TSE is one of the most important machines used for processing polymers, chemicals and foodstuff [1, 2]. At the AIChE meeting 2022, a novel twin-screw extrusion (TSE) model was presented [3]. A novel 3D-1D simulation method had been developed to model polymer extrusion in a twin-screw extruder by combining detailed 3D simulations with a faster 1D approach, with the 3D part using DEM simulations of key screw elements (RVEs) to capture detailed behavior like torque, pressure, filling, and residence time, while the 1D model bridges these detailed zones. This approach uses a look-up table built from precomputed 3D simulations of the conveying element under various outlet pressures, which enables fast 1D predictions. During the full simulation, only the kneading and outlet elements are simulated in 3D, while the rest are handled with the efficient 1D model. The limitations of this approach however is the still significant run-time of the simulation.

On the other hand, CFD and DEM models of the meso-scale can also be used to inform a 1D or simplified transport model for a specific process. For the TSE, the DEM simulations and the according data can also be used to create a frequency-space transfer function for the residence time distribution (RTD). Results are shown in Fig. 1. This allows for much faster execution of the python-based model.

For connecting such highly customized process models to existing other models such as the fluids and thermos libraries [5], we have developed a web platform called engicloud [4] that allows flexible combinations of existing models, modifications thereof and customized own models.

In summary, this presentation shares – by the means of exemplary highlights - our experience of 15 years of developing modelling projects and products to serve the CAE and materials modelling community – most notably LIGGGHTS and CFDEMcoupling [6], and now most recently the SaaS platform engicloud, that are useful for process modeling at all scales.

Finally, we will outline the need for FAIR (findable, accessible, interoperable, reusable) data handling and collecting, aggregating, connecting, sharing modelling results and tools and our approach to it.

Bibliography

[1] A. Eitzlmayr, G. Koscher, G. Reynolds, Z. Huang, J. Booth, P. Shering and J. Khinast, "Mechanistic modeling of modular co-rotating twin-screw extruders," International journal of pharmaceutics, vol. 474, no. 1-2, pp. 157-176, 2014

[2] Co-rotating twin-screw extruder, Carl Hanser Verlag GmbH, 2012

[3] R Togni, C Kloss, M Lubej, ML Eggersdorfer, “3D-1D Modelling of Twin-Screw Extruder”, - 2022 AIChE Annual Meeting, 2022

[4] engicloud modelling platform, https://www.engicloud.ai/

[5] fluids and thermo libraries, https://github.com/CalebBell

[6] LIGGGHTS DEM and CFDEMcoupling CFD-DEM software, www.cfdem.com