2025 AIChE Annual Meeting

(291d) 3D Dynamics of Vibro-Fluidized Beds Revealed By Magnetic Resonance Particle Tracking

Authors

Recently, we developed a novel measurement technique based on nuclear magnetic resonance that is able to track particles in 3D granular systems [4], dubbed Magnetic Resonance Particle Tracking (MRPT). Unlike imaging techniques that obtain information at the density level, MRPT can recover full trajectories of many particles simultaneously at the micron and millisecond level.

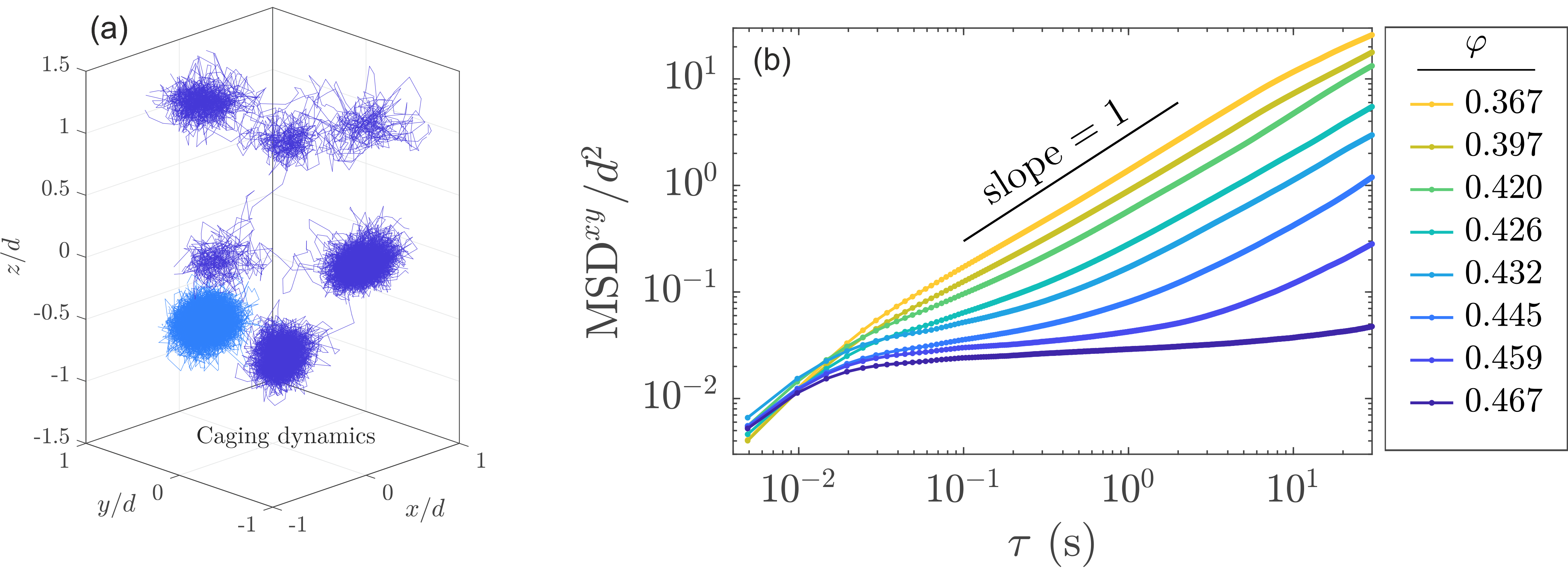

In this work, we leverage the capabilities of MRPT to investigate the 3D dynamics of a vibro-fluidized bed at various volume fractions. For low volume fractions, we observe diffusive behavior of the particles characterized by a linear time dependency of the mean squared displacement. As the volume fraction is increased, the particle dynamics slow down and individual grains become trapped by their neighbors, a phenomenon known as caging [2]. This process eventually breaks the ergodicity of the system and the bed cannot mix properly anymore. Thanks to the high spatiotemporal resolution of MRPT, we can capture these caging dynamics precisely (Fig. 1a). We identify the time scales and volume fractions at which this phenomenon occurs, providing direct insight into the duration of the system’s structural memory (Fig. 1b). This, in turn, serves as a measure of the mixing efficiency.

References

[1] H. M. Jaeger, S. R. Nagel, and R. P. Behringer, Rev Mod Phys 68, 1259 (1996).

[2] D. Kunii and O. Levenspiel, Fluidization engineering (Elsevier, 2013).

[3] K. Binder and W. Kob, Glassy Materials and Disordered Solids: An Introduction to their Statistical Mechanics (World Scientific, 2011).

[4] M. Suter, J. P. Metzger, A. Port, C. R. Müller, and K. P. Pruessmann, (2025), p. arXiv:2503.22425.

Figure 1. (a) Particle trajectories reveal dynamics such as caging. (b) The mean squared displacement shows diffusive behavior for low volume fractions .