2024 AIChE Annual Meeting

Optimized Solvent-Based Separation and Recrystallization of Co-Produced PHB Polymer and Indigo Pigments Synthesized Via E. coli Bioreactions

Ourobio’s research and development efforts before Summer 2024 led to a breakthrough opportunity to co-produce indigo pigment alongside PHB (Poly-hydroxybutyrate) using fermentation. However, challenges in quantifying, extracting, and purifying the indigo pigment remained unsolved. The primary issue was the lack of an accurate quantification method, which was initially addressed by developing a UV/Vis spectroscopy method that proved unreliable. This was replaced by a more accurate LC-MS-based quantification approach. The LC-MS method involved constructing a standard curve based on peak areas of 95% pure synthetic indigo measured at 615 nm, using DMSO as the solvent. Additionally, the extraction process underwent major revisions, moving from an aqueous-based extraction method to a more efficient solvent-antisolvent method. The aqueous approach, which involved reduction, separation, and reoxidation, was replaced with a solvent-based approach using DMSO due to its high solubility for indigo and its ability to facilitate solvent removal in subsequent steps. After biomass was separated via centrifugation at 7000 rpm, indigo was precipitated using anti-solvents, namely ethanol and water, resulting in a final product that was approximately 80% pure.

LC-MS Method Development:

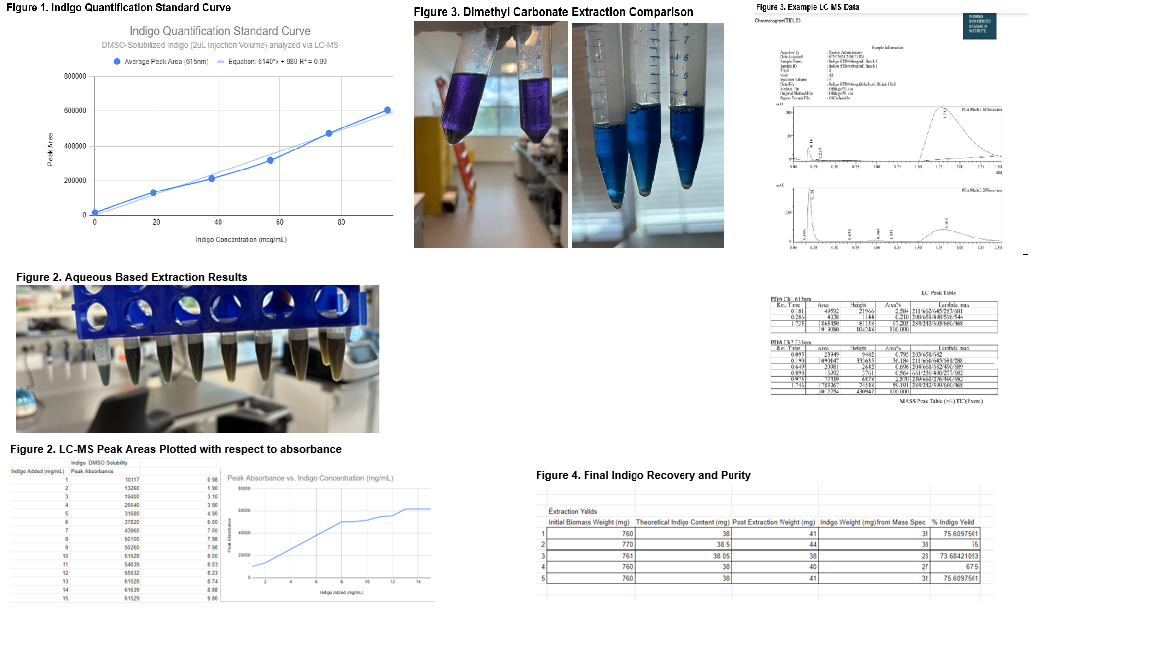

In the method development stage, a standard curve for indigo quantification was created. Triplicate stock solutions of pure indigo, sourced from Sigma-Aldrich, were solubilized in DMSO and diluted into five different concentrations, ranging from 0 to 100 micrograms of indigo per milliliter of DMSO. These solutions were evaluated using LC-MS, and the peak area of indigo at 615 nm was recorded. A linear correlation between the peak area and the indigo concentration was observed, with an R² value of 0.99, indicating high reliability and accuracy of the quantification method. This step established a reproducible method to quantify indigo concentrations in future samples with high precision.

Challenges with Aqueous-Based Extraction:

The initial extraction method used was an aqueous-based process, similar to the vat dyeing of textiles. Indigo was solubilized using a reducing agent and then reoxidized to a water-insoluble form after separation from the biomass. However, this process proved inconsistent. The aqueous extraction method presented challenges, including incomplete separation of biomass and difficulties with the reduction-oxidation cycle. Lower concentration samples (2.5 mg/mL to 7.5 mg/mL) often failed to reoxidize the leuco-indigo into usable indigo, making the samples essentially unusable. On the other hand, higher concentration samples had significant issues with biomass separation, resulting in poor indigo recovery. The aqueous-based method was ultimately deemed unreliable for consistent extraction of indigo pigment.

Transition to Solvent-Based Extraction:

The switch to a solvent-based extraction method marked a significant improvement. DMSO was chosen as the solvent due to its high solubility for indigo and its compatibility with subsequent solvent removal processes. In this improved method, DMSO was heated to remove any water that it had absorbed, ensuring maximum solubility for indigo. After heating, the indigo-laden solution was centrifuged at 7000 rpm for 30 minutes to separate biomass, followed by precipitation of the indigo pigment using cold ethanol and DI water as anti-solvents. This method not only enhanced biomass separation but also yielded purer indigo samples. A comparison between Dimethyl Carbonate (DMC) and DMSO as solvents showed that DMSO was significantly more effective in separating indigo from biomass, as evidenced by cleaner, off-white biomass pellets compared to the darker pellets in DMC-based extractions.

Figure Highlights:

- Figure 1: Standard curve for indigo quantification using LC-MS, showing a linear relationship between peak area and concentration.

- Figure 2: Results of aqueous-based extraction, highlighting the issues of incomplete oxidation in lower concentrations and poor biomass separation in higher concentrations.

- Figure 3: Comparison between Dimethyl Carbonate (DMC) and DMSO in solvent-based extraction. DMSO performed better in separating indigo from biomass.

Using LC-MS data, it was determined that indigo reached a maximum solubility of approximately 7 mg/mL in DMSO. Concentrations higher than this resulted in a sharp decline in accuracy, which was consistent with the findings in a 2015 study by Dr. Vizcaino Caston, who optimized similar extraction protocols. These findings further validated the choice of DMSO as the primary solvent for the extraction process.

Optimized Extraction Procedure:

The final extraction procedure was developed and refined based on the results of these trials. First, DMSO was heated to 100°C for 20-30 minutes to remove any absorbed water. Biomass was then dissolved in DMSO at a concentration of 7.6 mg/mL, heated, and stirred for 30 minutes to ensure complete dissolution of indigo without exceeding the boiling point of DMSO. After centrifugation at 7800 rpm for 10 minutes, the supernatant containing the indigo was decanted. If any remaining biomass was dark, a second extraction with DMSO was performed. Precipitation of indigo was achieved by adding ice-cold ethanol at three times the volume of the original solution, followed by DI water to aid in agglomeration. After allowing the solution to stir for 2 hours, the precipitated indigo was separated through centrifugation, and the pellet was washed multiple times with DI water to remove any traces of DMSO. Finally, the indigo was lyophilized overnight in a -80°C freezer to obtain a dry product.

Discussion and Results:

The initial challenges with aqueous-based extraction stemmed from difficulties in maintaining consistent redox reactions and biomass separation. The reducing solution, consisting of NaOH and fructose, was likely solubilizing some biomass along with the indigo, leading to inconsistent results. Precipitation using HCl as an oxidizing agent was inconsistent, sometimes yielding white biomass instead of indigo, further complicating the process. However, in later trials, it was observed that allowing samples to settle for several days resulted in some separation of biomass and indigo, prompting the introduction of centrifugation as a method to speed up this process.

The solvent-based extraction method, using DMSO, proved to be more reliable and efficient. Further experiments refined the extraction process, focusing on optimizing the concentration of biomass and adjusting solvent ratios. Higher biomass concentrations yielded more indigo, though a second extraction was sometimes necessary to dissolve all the indigo. Precipitation worked best with a combination of ethanol and DI water, as neither solvent alone was sufficient to precipitate indigo from the DMSO solution. Longer stirring times improved indigo precipitation, though stirring for over 2 hours led to product degradation. The drying process was also optimized through lyophilization, and multiple DI water washes effectively removed DMSO from the samples.

By the end of the summer, the final purity of extracted indigo reached approximately 70-80%, with PHB being the primary contaminant. This suggests that future work could focus on improving the purification process, potentially by applying PHB extraction protocols. Additional experiments could also explore the possibility of reusing DMSO to lower the costs associated with the extraction process. Moving forward, Ourobio plans to scale up production and deliver several grams of indigo to potential customers, continuing with the successful extraction methods developed during this research.