2024 AIChE Annual Meeting

Cycling Effects & Stability of Polythiophene-Coated Lfp Cathode Current Collectors

As global initiatives to mitigate anthropogenic carbon dioxide contributions

intensify, electrochemical storage systems are poised to play an integral role in

the eco-friendly metamorphosis of electricity and transportation. Lithium- ion

battery (LIB) have a high energy density and low self-discharge compared to

other batteries utilized within electric vehicles, making them the most common

battery. While advances in LIB technologies continue, significant obstacles to

LIB adoption persist in the high-demand grid and transportation sectors, such as

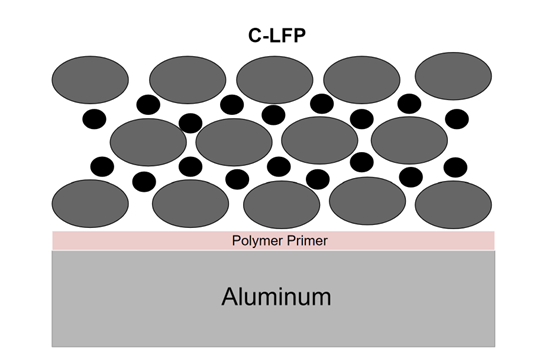

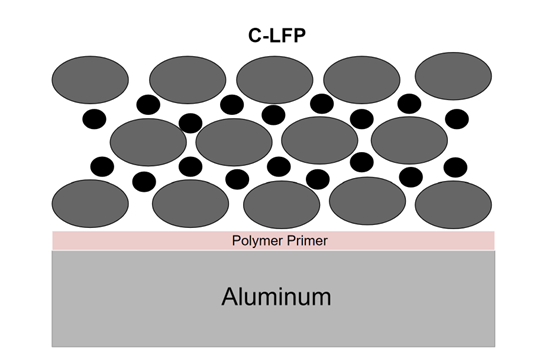

within extending their useful life. This study explores the use of polythiophene

and its derivatives (poly(3-butylthiophene) (P3BT), poly(3-hexylthiophene)

(P3HT), and poly(3-octylthiophene (P3OT)) as priming materials coated on the

aluminum cathode current collector surface in Lithium Iron Phosphate (LFP) LIB.

The use of an electroconductive polymer would ensure good contact between

the active materials and conductive additive and the current collector, which

would protect the electrode from corrosion through its cycling. This method is

expected to enhance battery stability by preventing electrode materials

decomposition, thereby extending battery life. Additionally, the high electronic

conductivity of the polymers is predicted to improve cycling ability, resulting in

increased Coulombic efficiency, and rate capacity. There is also evidence for the

improved stabilization of the Cathode Electrolyte Interphase (CEI) during the first

several cycles that would create a protect layer outside the active material, and

further limit side reactions. This preparation technique holds promise for

enhancing EV battery performance and longevity, with the prospect of future

research for the optimization of the technique.

intensify, electrochemical storage systems are poised to play an integral role in

the eco-friendly metamorphosis of electricity and transportation. Lithium- ion

battery (LIB) have a high energy density and low self-discharge compared to

other batteries utilized within electric vehicles, making them the most common

battery. While advances in LIB technologies continue, significant obstacles to

LIB adoption persist in the high-demand grid and transportation sectors, such as

within extending their useful life. This study explores the use of polythiophene

and its derivatives (poly(3-butylthiophene) (P3BT), poly(3-hexylthiophene)

(P3HT), and poly(3-octylthiophene (P3OT)) as priming materials coated on the

aluminum cathode current collector surface in Lithium Iron Phosphate (LFP) LIB.

The use of an electroconductive polymer would ensure good contact between

the active materials and conductive additive and the current collector, which

would protect the electrode from corrosion through its cycling. This method is

expected to enhance battery stability by preventing electrode materials

decomposition, thereby extending battery life. Additionally, the high electronic

conductivity of the polymers is predicted to improve cycling ability, resulting in

increased Coulombic efficiency, and rate capacity. There is also evidence for the

improved stabilization of the Cathode Electrolyte Interphase (CEI) during the first

several cycles that would create a protect layer outside the active material, and

further limit side reactions. This preparation technique holds promise for

enhancing EV battery performance and longevity, with the prospect of future

research for the optimization of the technique.