2024 AIChE Annual Meeting

(73j) 3-Reactor Chemical Looping System for Point Source CO2 Capture and Subsequent Utilization for Liquid Fuel Production

Authors

Rushikesh Joshi - Presenter, The Ohio State University

Krutarth Pandit, The Ohio State University

Xiaofeng Jiang, The Ohio State University

Falguni Akulwar, Ohio State University

Danwyn Aranha, The Ohio State University

Liang-Shih Fan, The Ohio State University

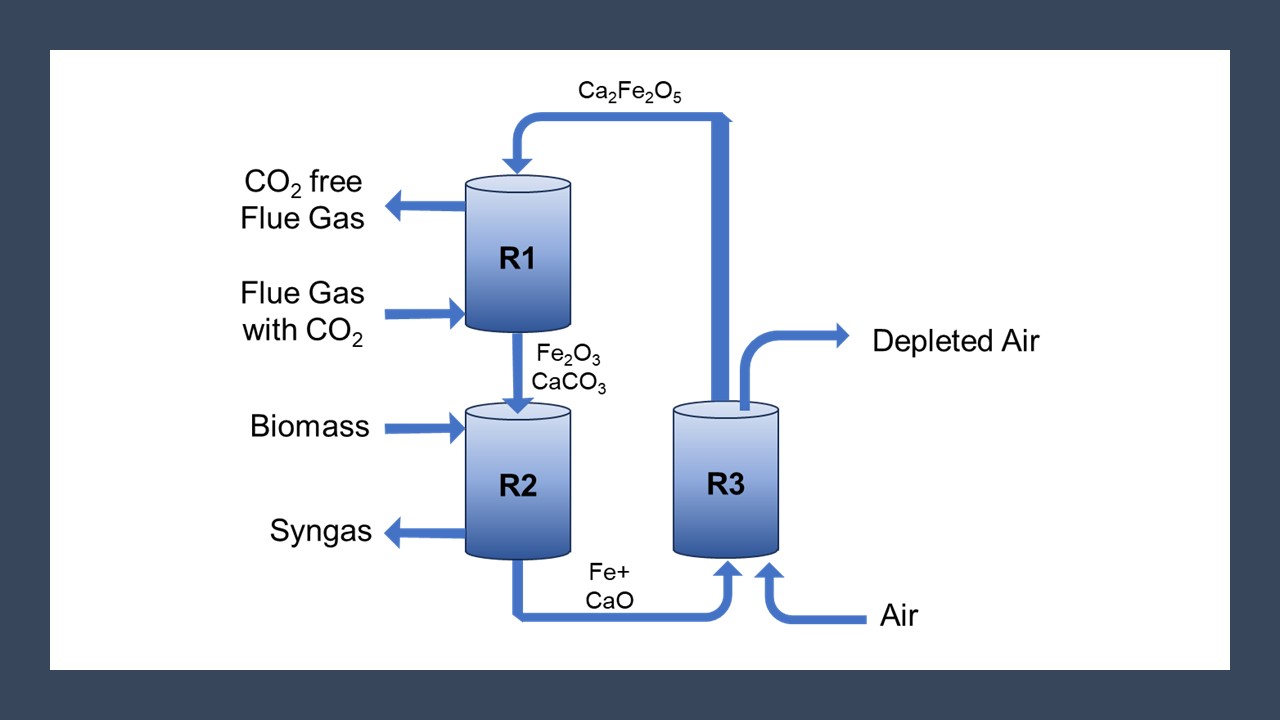

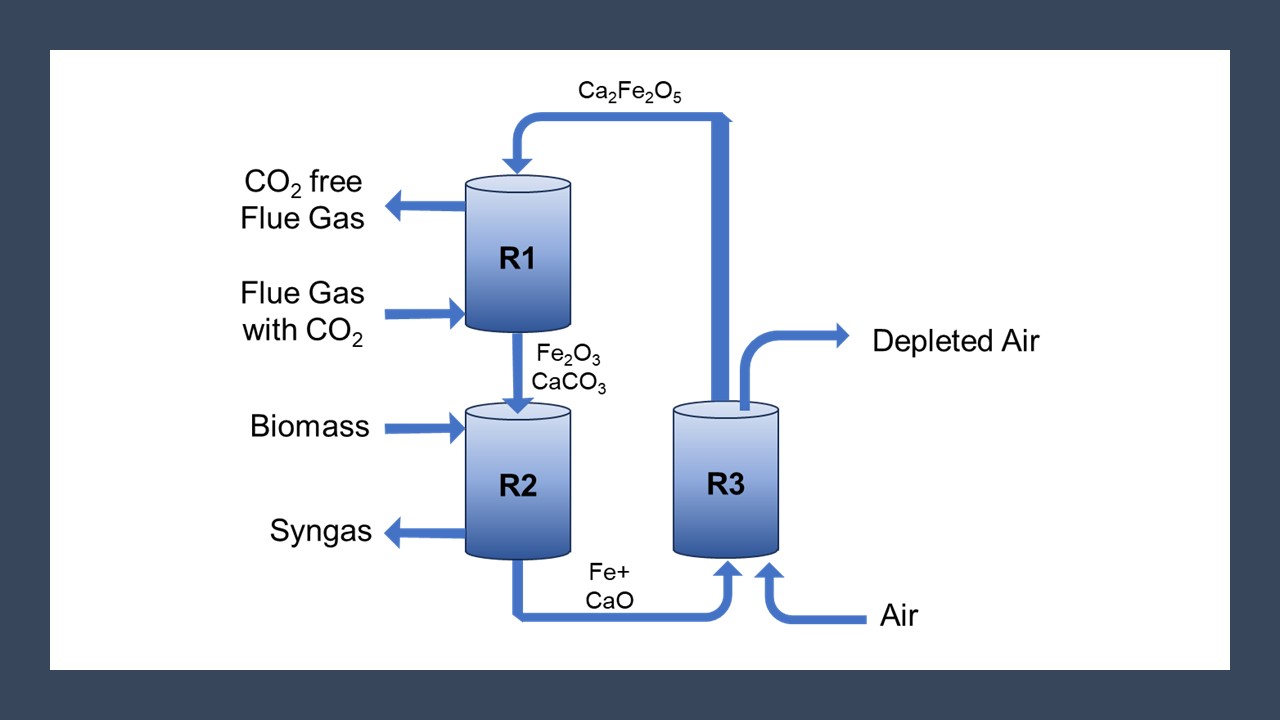

Owing to the rising emissions and climate change, CO2 capture and utilization from point sources is the need of the hour. Technologies that can, therefore, capture the CO2 and then utilize it to form chemical products can lead to higher applicability. A novel 3-reactor chemical looping system is proposed with calcium ferrite (Ca2Fe2O5) oxygen carrier material for the capture and utilization of point source CO2 and its subsequent utilization in liquid fuel production. In the first reactor, a flue gas stream is inlet counter-currently on the oxygen carriers, wherein the Ca2Fe2O5 oxygen carriers get carbonated to form CaCO3+Fe2O3. The carbonated oxygen carriers are then transported to a second reactor, wherein they react with biomass to form high-purity syngas, which can then be integrated into the Fischer-Tropsch process for liquid fuel generation. The reduced oxygen carriers are then transported to a third reactor wherein the reduced oxygen carriers are reacted with air to regenerate the oxygen carriers back to Ca2Fe2O5. Process simulation studies have been conducted to design the process and optimize the parameters. It is observed that the carbonation occurs better at a lower temperature, and the gasification reaction occurs with higher efficiency at a higher temperature. Therefore, heat integration strategies have been discussed to optimize process efficiency and achieve autothermicity. Further thermogravimetric experiments have been conducted to test the feasibility of the process.