2024 AIChE Annual Meeting

(735bb) On Electrocoagulation and Novel Hybrid Coagulation Method for Enhanced NOM Removal in Drinking Water Treatment.

Natural organic matter (NOM) is a complex mixture of organic substances commonly found in surface and ground waters. Inherently, NOM is not toxic, but its presence in drinking water sources can significantly impact water quality, impair the efficiency of the drinking water treatment processes, and lower biostability in the supply network. On top of that, serious health risks are posed by the products of NOM reactions with disinfection agents – disinfection by-products, DBPs. Therefore, efficient NOM removal is paramount in drinking water treatment facilities for which various separation processes were developed and employed. However, with the ongoing global change, the composition of NOM in surface water alters, the levels increase, and their separability decreases. This calls for developing enhanced separation methods to improve the performance of existing facilities and alleviate the advanced (and expensive) separation techniques employed in any new facility. In the response, we present a novel hybrid coagulation method for NOM removal comprising conventional chemical coagulation (CC) and electrocoagulation (EC) combined into one enhanced separation step easily integrable into existing water treatment facilities.

Introduction

In the water treatment industry, both CC and EC are basic separation techniques based on destabilizing colloidal suspensions by adding metal coagulants and their consequent separation as precipitates. Both coagulation methods utilize a metal cation – usually Al3+ or Fe3+ - as the coagulation agent; however, they differ in the cation introduction. Whilst CC achieves this by adding a corresponding water-soluble salt, EC is based on a direct electrolytic dissolution of a metal electrode. The EC was proven to be a comparable or more efficient coagulation method for various pollutants in wastewater treatment, leveraging easier operation control, higher coagulant utilization, and lower sludge production than a conventional CC. For drinking water treatment, EC is less frequently used; it is utilized mainly for mobile water treatment units or removing heavy metals from ground waters [1]. Although few studies report the successful use of EC for NOM removal, the data are not compared to conventional CC, and coagulant dosages are mostly higher than acceptable for industrial use.

To develop a method for enhanced NOM removal and fill the knowledge gap in EC efficiency, we performed extensive experimental research comparing the efficiency of CC and EC for NOM removal from natural surface water. This work follows our previous research on optimizing chemical coagulation conditions for NOM removal [2]. The experiments were performed with Al- and Fe-based coagulants under optimal coagulation pH. Based on the obtained results, a hybrid coagulation method was developed, combining the economical treatment via CC with the efficiency of EC for effective and sustainable NOM removal.

Experimental

The experiments were conducted with natural surface water from the reservoir Vrchlice (Czech Republic), a source for the near-located DWTF. The raw water contains ~10 mg/L of dissolved organic carbon (DOC), of which almost 40% cannot be removed by conventional CC using either ferric or aluminum-based coagulants. The CC experiments were performed according to the standardized methodology using ferric sulfate and aluminum sulfate dosing from 4 mg/L to 40 mg/L of the metal at the pH optimized for each coagulant - 5.5 for Fe2(SO4)3, 6.8 for Al2(SO4)3. Before the coagulant addition, the water pH was adjusted with HCl/NaOH solution to the desired level; then, the coagulant was dosed, and the jar was stirred at a mean shear rate of 200 s-1 for 60 seconds. After the rapid mixing period, the mixing intensity was lowered to the shear rate of 40 s-1 for 30 minutes of the flocculation stage.

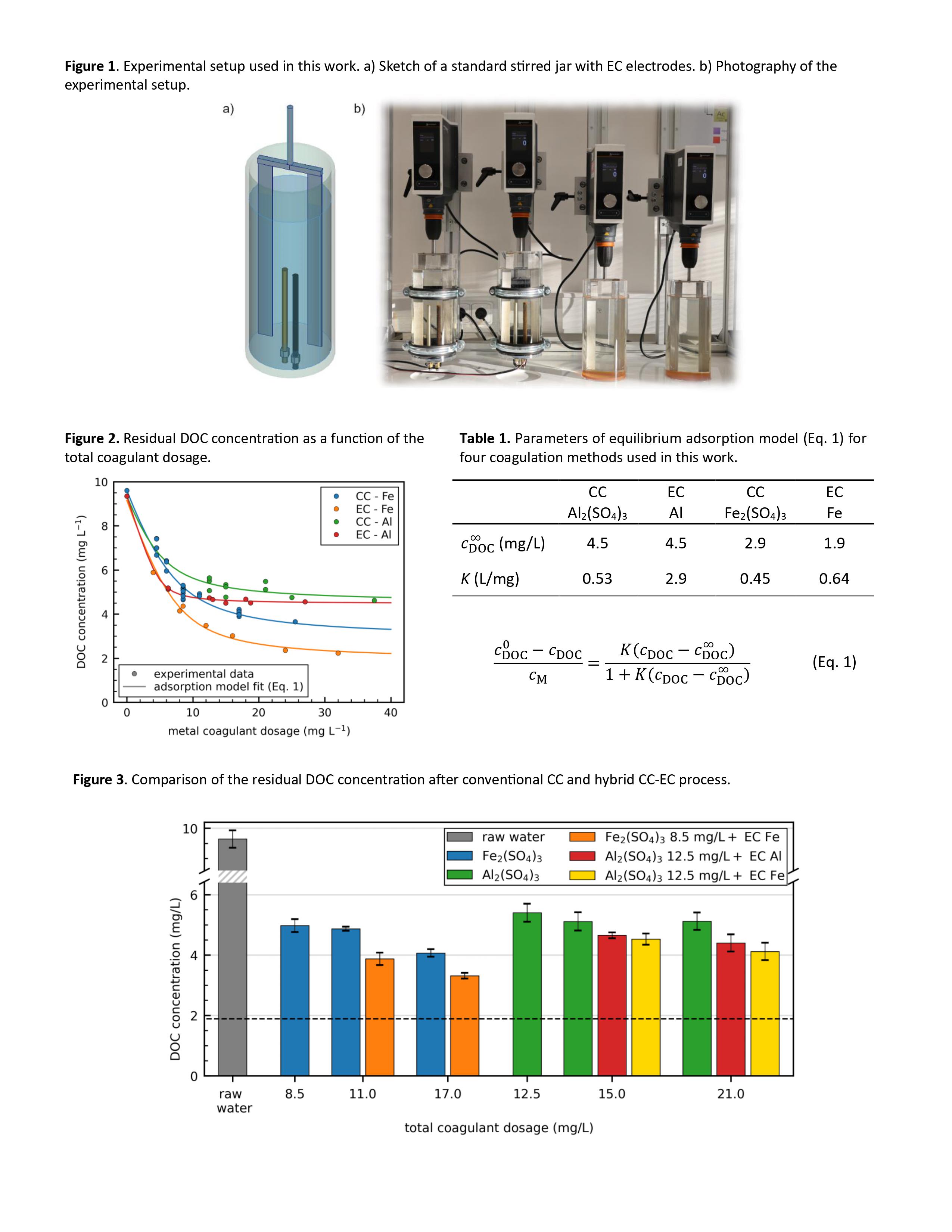

The EC experiments were conducted in a 2L stirred jar housing two cylindrical electrodes with 32 cm2 active surface area. The aluminum and mild steel electrodes were used as anodes (sacrificial electrodes); the cathode was made of stainless steel. The electrodes were connected to a DC power supply unit operated in a constant current regime with a current intensity of 0.10A. The picture of the experimental setup is shown in Figure 1. Similar to CC experiments, the EC experiments started with a pH adjustment, after which the electrolytic dissolution of the sacrificial electrode was performed in a jar stirred at a mean shear rate of 40 s-1. The metal dosage from 1 mg/L to 40 mg/L was used; the duration of the dissolution step was calculated based on the calibration experiments. After the coagulant dosage, the electrodes were removed from the solution, and the jar content was mixed for an additional 30 minutes to allow for aggregate growth.

The hybrid CC-EC experiments were performed, starting with standard CC conditions using an optimal dosage of coagulants determined in the previous investigation (8.5 mg/L of Fe or 12.5 mg/L of Al) [2]. After 10 minutes of the flocculation stage, the secondary coagulant (1 mg/L – 20 mg/L) was dosed using EC, and the jar content was left stirred for an additional 20 minutes of the flocculation stage.

After all the flocculation experiments, the solution was left for 15 minutes to settle; then, the sample of 250 mL was taken, centrifuged for 20 minutes at 4000 rpm, and analyzed for final pH, TOC concentration, and residual metal content.

Results and discussion

First, the potential of CC and EC for DOC removal was investigated separately using either Fe and Al sacrificial electrodes or Fe2(SO4)3 and Al2(SO4)3 as chemical coagulants. The results are shown in Figure 2 as the dependence of residual DOC concentration on the metal coagulant dosage. In all cases, the residual DOC concentration follows the Langmuir adsorption model proposed by Edwards [3] – Eq. 1. In the cases of aluminum coagulant, the fraction of non-purgeable DOC is almost identical, regardless of the coagulant addition method. On the other hand, in the case of EC performed with the mild steel sacrificial electrode, the fraction of non-purgeable DOC is significantly lower, and the coagulant utilization is higher than in the cases of Al-based coagulation and Fe-based CC – consult the model parameters listed in Table 1 - offering a promising method for DOC removal enhancement.

Despite the substantially higher potential of EC with iron sacrificial electrodes for NOM removal in drinking water treatment, technical and economic difficulties limit its wide industrial utilization. While in industrial wastewater treatment, EC is proven to be an effective and sometimes cheaper alternative method to CC for the removal of various pollutants, the combination of low drinking water conductivity and its high production rates affects EC economy and technical feasibility. This usually prevents a full replacement of CC with EC as generating tens of mg/L of metal at the common production rates of hundreds to thousands of L/s becomes too expensive. However, these limitations can be partially overcome by combining the CC and EC into a hybrid process, employing EC as a secondary coagulant dosage method with relatively low coagulant dosage.

This work combined CC and EC into one treatment step, scheduling EC dosing 10 minutes after the CC. The optimal dosage of chemical coagulant determined in [2] was followed by 2.5 mg/L and 8.5 mg/L of metal dosed via EC. Figure 3 compares the DOC removal efficiency of the hybrid coagulation method to that of a conventional CC. It is shown that with only 2.5 mg/L of Fe dosed via EC, the DOC residual concentration is decreased significantly. In the case of the Fe-Fe coagulation system, the DOC reduction of an additional 1.1 mg/L is achieved; using only CC, such an efficiency would be achieved using more than 20 mg/L of Fe in total. In the Al-Fe and Al-Fe coagulation systems, a slightly lesser reduction of 0.9 mg/L in DOC is achieved; however, the resulting DOC concentrations are at or below the minimal values achievable with conventional Al-based chemical coagulation regardless of the coagulant dosage. With Fe-Fe and Al-Fe coagulation systems dosing 8.5 mg/L of Fe via EC, the resulting DOC concentration is always significantly lower than it can be achieved with CC using up to 40 mg/L of metal.

Conclusions

The EC is a more effective NOM removal coagulation method than the CC, which uses the same coagulant dosage. However, the EC's technical and economic aspects in drinking water treatment limit it from fully substituting CC. To overcome these difficulties and leverage the EC's efficiency, a hybrid coagulation method is developed and tested, replacing the CC only partially. The efficiency of the developed hybrid method is tested on natural surface water, for which its superiority is evidenced. The method can be relatively easily integrated into existing water treatment facilities, offering a simple method for NOM removal enhancement.

[1] Mousazedeh, M. et al. (2021). Environmental Science and Pollution Research 28(32), 43143.

[2] Pivokonsky, M. et al. (2024). Journal of Water Process Engineering 57, 104660.