2024 AIChE Annual Meeting

(702c) Quantum Federated Learning-Based Collaborative Manufacturing

Till now, several machine learning algorithms have been applied for defect detection in manufacturing, contributing to improved product quality and operational efficiency [1]. Indeed, the significance of high-quality, clean, well-labeled, and sufficiently large datasets in ensuring the success of machine learning models [2][3]. Stringent privacy measures may restrict access to certain data, limiting the amount of information available for model training. Stringent privacy measures may restrict access to certain data, limiting the amount of information available for model training. The sensitivity and value of manufacturing data derive from its indispensable role in modern manufacturing, its pivotal contribution to technological advancement, and its encompassment of crucial details about the manufacturing process and materials utilized. Therefore, any breach in data security poses a multifaceted risk that extends beyond immediate financial losses to encompass long-term damage to a company's reputation and competitive standing [4]. Balancing the need for data privacy with the requirements for effective machine learning in manufacturing involves adopting advanced privacy-preserving techniques and fostering collaboration within the industry while respecting legal and ethical boundaries.

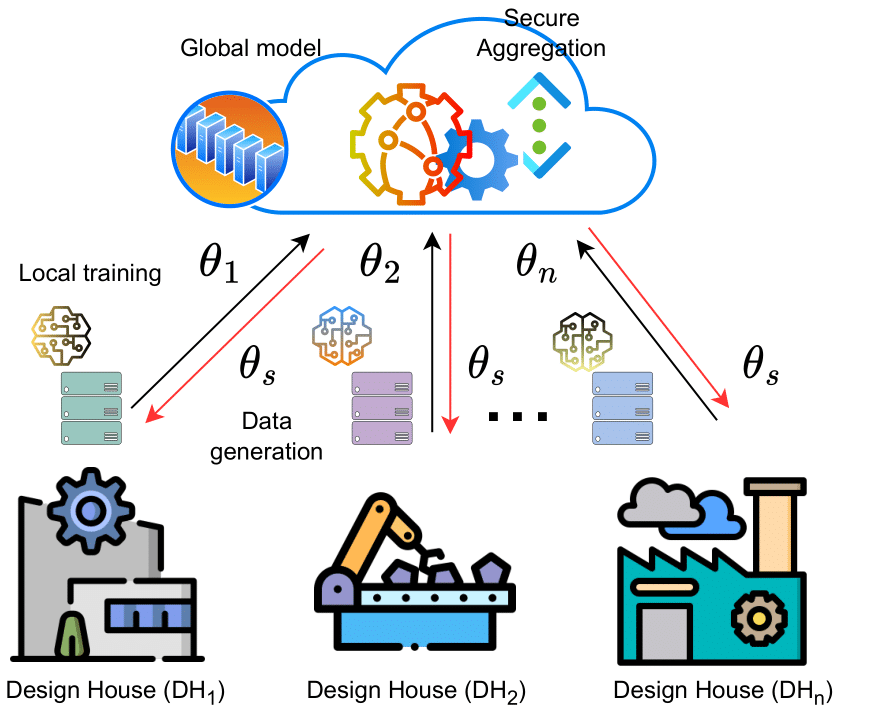

In recent times, Federated Learning (FL) has transformed the research landscape, enabling model training across decentralized clients without the need for a direct exchange of raw data [5]. In the last few years, there has been a rapid increase in the adoption of Quantum Machine Learning (QML) as a framework to tackle computational challenges across several domains [6].

In this presentation, a privacy-preserving quantum federated learning framework consisting of quantum circuits to collaboratively address defect detection across diverse manufacturing units. The findings indicate that the suggested framework demonstrated a defect detection performance on par with centralized learning, which involves data sharing among manufacturers/clients but compromises data privacy. Moreover, it notably surpassed individual learning, wherein each manufacturer develops a model using its proprietary data. Furthermore, the study reveals that incorporating data diversity both within and across clients enhances the performance of quantum federated learning. Moreover, the quantum global model does not incur a substantially higher training cost compared to centralized learning.

References

- T. Yu, G. H. Lin, I. H. R. Jiang, & C. Chiang, “Machine-learning based hotspot detection using topological classification and critical feature extraction.” In Proceedings of the 50th annual Design Automation Conference, pp. 1-6, 2013.

- Ding, J. Torres, & D. Pan, “High-Performance lithography hotspot detection with successively refined pattern identifications and machine learning.” IEEE Transactions On Computer-Aided Design Of Integrated Circuits And Systems. 30, 1621-1634 (2011).

- Shin & J. Lee, “Accurate lithography hotspot detection using deep convolutional neural networks”. Journal of Micro/Nanolithography, MEMS, And MOEMS. 15, 043507-043507 (2016)

- Mehta, M., & Shao, C. (2022). Federated learning-based semantic segmentation for pixel-wise defect detection in additive manufacturing. Journal of Manufacturing Systems, 64, 197-210.

- McMahan, B., Moore, E., Ramage, D., Hampson, S. & Arcas, B. Communication-efficient learning of deep networks from decentralized data. Artificial Intelligence And Statistics. pp. 1273-1282 (2017)

- Biamonte, J., Wittek, P., Pancotti, N., Rebentrost, P., Wiebe, N., & Lloyd, S. (2017). Quantum machine learning. Nature, 549(7671), 195-202.