2024 AIChE Annual Meeting

(693h) Understanding the Complex Interplay between Morphologies and Material Properties in Pluronic Systems: Insights from Dissipative Particle Dynamics.

Authors

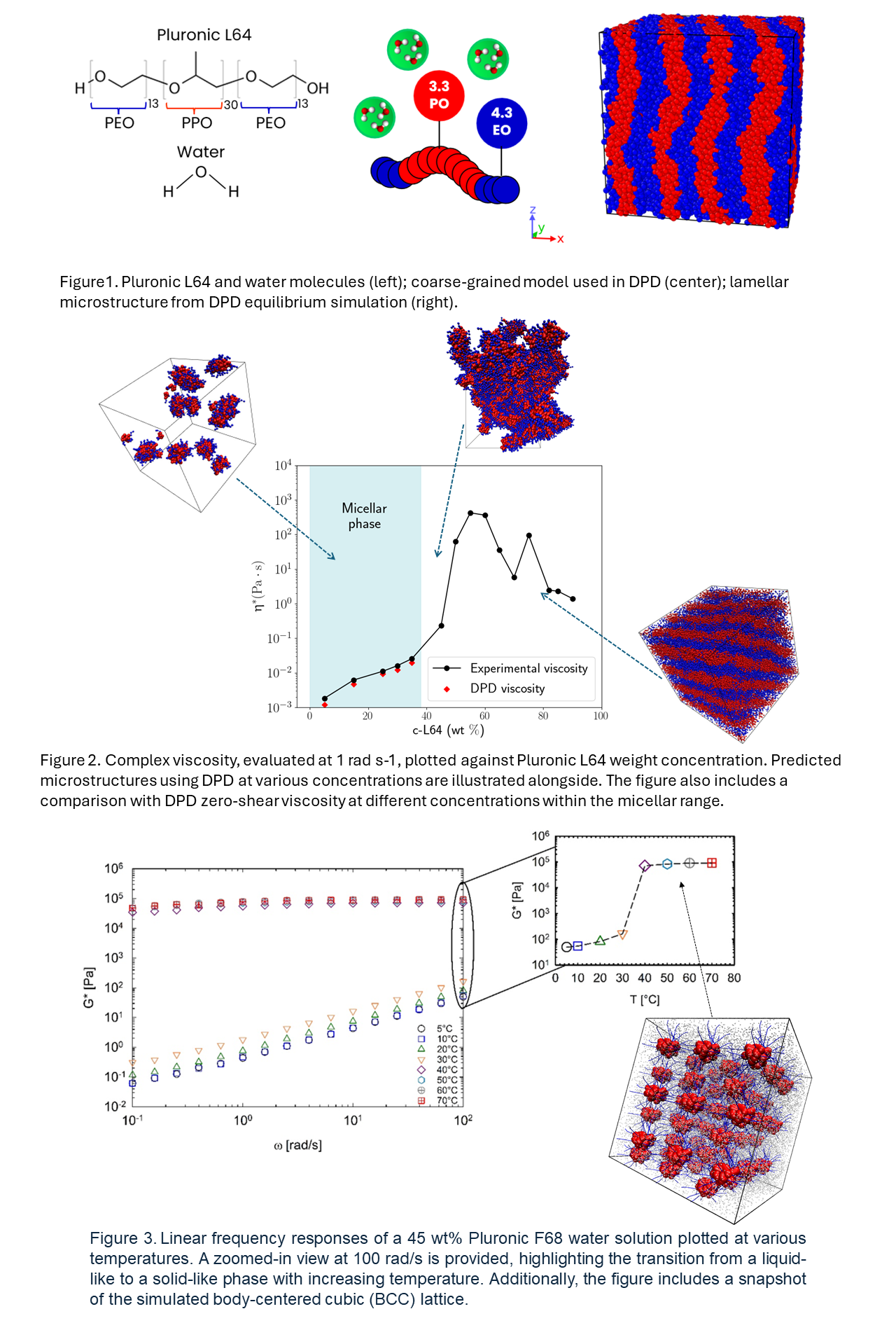

Building upon these considerations, this study proposes the use of DPD to conduct robust virtual experiments, validated through comparison with real-world experiments, focusing on Pluronic systems in water. The aim is to discern the intricate interplay between morphology and resultant properties. Two distinct applications are proposed, each involving a different type of Pluronic.

The initial part of this study involves simulating binary mixtures of Pluronic L64 and water at room temperature. The aim is to explore how variations in concentration influence the evolution of microstructures and rheological properties. In fact, by varying the concentration, a spectrum of morphologies emerges, encompassing micellar, hexagonal, lamellar, and reverse micellar structures. This diversity in microstructures results in a complex rheology. This work makes use of an equilibrium approach for the viscosity estimation [1]. This is an important step before evaluating the rheological behaviour of structured fluids occurring under fluid motion or temperature change. In fact, it is important at first to assess the zero-shear viscosity of morphologically different formulations without perturbing them. Since the standard DPD model cannot describe real fluid transport properties, an “extended” DPD model is employed [2]. This research introduces a criterion aimed at estimating non-conservative interaction parameters. The objective is to accurately capture the experimental trend of viscosity as a function of concentration. The study successfully replicates the morphological transitions induced by polymer concentration, aligning closely with the experimental phase diagram. Morphological characterization is conducted using a clustering algorithm, enabling the identification of distinct aggregates, and offering insights into their size and shape variations. This approach facilitates the detection of different microstructures across concentrations, as evidenced by the corresponding behavior of quantitative descriptors. The viscosity predictions derived from the simulations exhibit strong agreement with experimental data, particularly at lower polymer concentrations [3]. This suggests the efficacy of the model in capturing the rheological behavior of the system under these conditions. However, further investigations are needed to extend the applicability of the model to higher polymer concentrations.

The second part involves simulating the behavior of Pluronic F68 in water, particularly focusing on its intriguing behavior at a concentration of 45% by weight (wt) across various temperatures. Notably, at elevated temperatures, the system exhibits a distinctive characteristic: it assembles into an ordered supramolecular structure known as the body-centered cubic (BCC) phase, resembling a solid-like structure. This observation holds significant implications, especially in the realm of drug delivery systems. Indeed, since many drug delivery systems rely on ordered and thermodynamically stable nanostructures, such as body-centered cubic phase, Pluronic F68 shows good promise as a candidate for therapeutic applications. The ability of adjusting and controlling the morphology and rheological properties of drug delivery systems in which a pharmaceutical molecule is loaded stands as hot topic in therapeutic applications where the release of a drug cargo in human body needs to be controlled and smart. By leveraging computational tools such as DPD in conjunction with real experiments, a wide range of scenarios can be explored accelerating the design process. The study conducts DPD simulations of systems composed by 45 wt% of Pluronic F68 and water, with varying amounts of diclofenac sodium, across different temperatures. Through DPD simulations, the research aims to discern how changes in temperature and the presence of diclofenac sodium influence the self-assembly behavior and rheological characteristics of the Pluronic F68-water system. To ensure the reliability and validity of the simulation results, they are compared and validated against experimental data obtained from an experimental work involving the use of scattering techniques and rheological measurements to characterize the nanostructure and rheological properties of the system under similar conditions [4,5]. By aligning the simulation results with experimental findings, the study aims to verify the accuracy of the DPD model in capturing the behavior of the Pluronic F68-water-diclofenac sodium system across different temperature and composition regimes.

[1] N. Lauriello et al., Computer Physics Communications 291 (2023) 108843.

[2] N. Lauriello et al., Physics of fluids 33 (2021) 073106.

[3] Pasquino et al., Soft Matter 15 (2019) 1396-1404.

[4] Di Spirito et al., Langmuir 40 (2024) 1544-1554.

[5] Di Spirito et al., International Journal of Pharmaceutics 644 (2023) 123353.