2024 AIChE Annual Meeting

(687f) High Solids Loading Aqueous Slurry Formation of Corn Stover before Pretreatment in a Fed-Batch Bioreactor

Authors

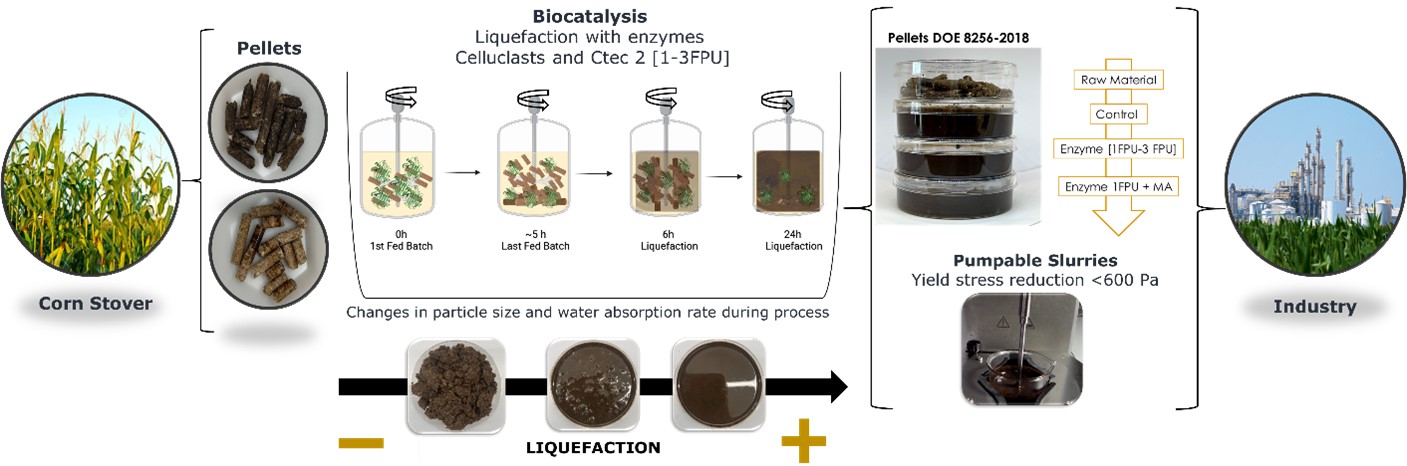

Slurries with concentrations of 300 g/L were obtained in a six-hour feed batch process using the commercial enzymes Celluclast 1.5L or Ctec-2 at 1FPU/g or 3 FPU/g of dry solids, based on the liquefaction mechanism (that is, the formation of slurry). We found that the insoluble lignin content of the different fractions was related to the absorption of water in pellets and the free water in slurries and that free water was a good indicator of the potential for a material to form a slurry. Higher flowability (lower yield stress) was found at higher lignin content, particularly for materials containing 26% lignin where the yield stress was reduced to 254Pa compared to 14% lignin mixtures with yield stresses of around 4000 Pa. We show through statistical and theoretical analysis that rheology modelling linked to compositional characteristics for biomass slurries can be used to predict material flow behavior in a biorefinery to optimize and achieve high solids loadings that enhance the production of ethanol for biofuels. These findings, along with the capability to create high-concentration slurries prior pretreatment, offers the opportunity to novel processing approaches that contribute to enhancing the efficiency and sustainability of the bio-based industry.