2024 AIChE Annual Meeting

(678d) CO2 Mass Transfer Model in Packed Columns for CFD Simulations

Author

A major challenge for DAC technologies is the energy efficiency of the CO2 capture process. Direct Air Capture systems often require a significant amount of energy to operate, which raises concerns about their overall sustainability and economic feasibility. The energy-intensive nature of DAC systems arises from several factors, including the need for large-scale air circulation on large-scale air-sorbent surface areas, the absorption of CO2 into sorbents, and the regeneration of the sorbents themselves.

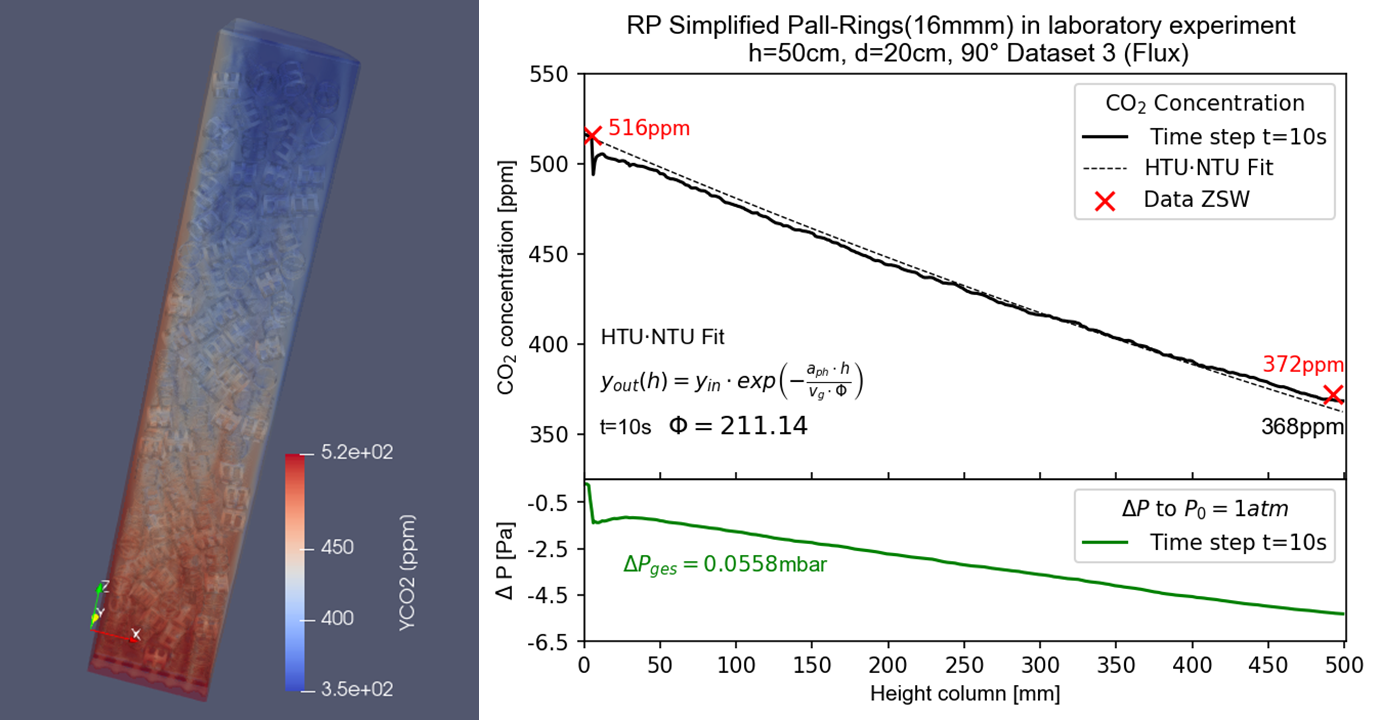

At the Center for Solar Hydrogen Research Baden-Württemberg (ZSW) in Stuttgart, the DAC system under study operates as a packed column in continuous operation. The system employs an absorption solution consisting of water and a chemical sorbent, which aids in effective gas-liquid separation. The column incorporates Pall-V-Ring elements, providing a large surface area to promote gas-liquid contact [2]. The main aim of this study is to develop a robust and validated toolchain, which encompasses the generation of the random-packing structure via CAD, the meshing step with CENTAUR [3] and subsequently conducting CFD with the in-house ThetaCOM software from the German Aerospace Center (DLR).

The ThetaCOM code is designed to simulate low Mach number flows including physical phenomena like turbulence, combustion, or heat radiation [4]. It is a 3D finite volume solver for unstructured grids. Through the incorporation of an absorption model, which will be described in the next paragraph, the functionality of the code is expanded to simulate realistic CO2 absorption. By recreating the geometry and using CFD, the correct absorption at all areas in the DAC system can be determined. This integrated approach allows for a detailed examination of the CO2 capture performance, helping to identify key parameters that improve its efficiency.

Building upon Fick’s laws of diffusion [5] and combining them with the work of Onda et al. [6] for the mass transfer parameters, a model for mass transfer of CO2 from the gas to the liquid phase in packed columns was developed. In addition to the physical mass transfer model, it was combined with an enhancement factor to account for chemical reactions.

In general, the diffusive flux of a component is dependent on the gradient of the concentration, where the direction of mass transfer goes from regions of high concentration to regions of low concentrations. The magnitude of said flux is correlated via the diffusion coefficient D. So, for the one-dimensional case in the direction of x the equation reads:

Ji = - D dci/dx

Given the units of Ji are mol or kg per area per time, depending on the units for the concentration, we can identify that the effective interfacial area aw of the mass transfer plays a crucial role in the overall sum of transitioned mol or kg per time. Provided with a solution for the concentration gradient by [7] and simplifying by introducing a mass transfer coefficient kL, the interfacial flux without chemical reaction reads, where ci* is the concentration at the interface and ci,0 in the bulk:

IJiI = 1/aw dn/dt = kL (ci* - ci,0)

The empirical formulas for the liquid-side transfer coefficient kL and overall surface wettability aw/at describe the influence of viscosity μL and surface tension σ of the sorbent solution.

kL = A ∙ (ρL/(μL g))-1/3 (L/(aw μL ))2/3 (μL/(ρL D))-1/2 (at∙d)0,4

aw/at = 1 - exp{ -1.45 (σc/σ)0.75 (L/(at μL ))0.1 ((L2 at)/(ρL2 g))-0.05 (L2/(ρL σ at ))0.2 }

Additionally, from these formulas it can be observed, that a further aspect is in the material of the packing elements to allow for good coverage of the liquid in the form of the critical surface tension σc and packing element size d. Selecting proper packing materials favors surface wettability and thereby increasing the overall transfer coefficient. The resulting CO2 mass transfer across the whole liquid-gas interface is then improved, thereby boosting efficiency without increasing energy demand.

The sorbent component used in this study is Polyethylenimin (PEI), which is commercially available and selectively reacts in the absorber with CO2 from ambient air. It has been successfully used for CO2 adsorption by impregnation over porous materials. PEI is a polymer with repeating units composed of amine groups [8]. Branched PEI is a fully amorphous polymer existing as a liquid at all molecular weights. For the packed column under study, PEI was diluted into water and different concentrations were investigated. The enhancement factor E is described via the ratio of mass transfer in the presence of a chemical reaction to mass transfer without a chemical reaction present.

Ji,chem = E · Ji,phys

It is easily recognizable that a higher enhancement factor is desirable for improving the overall CO2 absorption rate.

Potential optimization parameters are directly identified and verified under real life conditions by validating the mass transfer model based on a random packing experiment at laboratory scale. The parameter variation includes different sizes of Pall-V-Rings (16mm and 25mm) and different materials (polypropylene and metal). The liquid- and airflow rate were continuously varied to identify optimal operational settings. Special consideration was given to the variation of PEI concentration in the sorbent solution. While increasing the concentration of the chemical sorbent on the one hand increases the enhancement factor, the highly viscous nature of PEI is detrimental for the liquid-side transfer coefficient and surface wettability on the other hand.

Through the use of the mass transfer model and CFD simulations it is possible to recreate the trend of CO2 absorption and predict the optimal combination of the identified key parameters in the given operational DAC framework. By understanding the basic physical and chemical phenomena driving the CO2 absorption process at the interface, the developed toolchain can be used to increase the efficiency of the examined DAC system or can even be transferred to other facilities.

Our study underscores the pressing challenge of enhancing DAC efficiency, a pivotal concern for its sustainability and economic viability. Through a meticulous integration of computational fluid dynamics simulations and interfacial phenomena, we have developed a comprehensive approach, validated through laboratory-scale experiments, for optimizing DAC system performance. By refining key parameters such as surface wettability, transfer coefficients, and chemical reactivity, we have laid a robust foundation for advancing DAC technology. This study not only contributes to the specific DAC system examined but also offers insights applicable to broader efforts in enhancing carbon capture efficiency, thereby bolstering the global fight against climate change.

[1] Lackner et al. (2012): “The urgency of the development of CO2 capture from ambient air”, [https://doi.org/10.1073/pnas.1108765109]

[2] https://www.chemicalpackings.com/article/pallringtechdetails.html

[3] https://www.centaursoft.com/

[4] Setzwein et al. (2021): “An implicit high-order k-exact finite-volume approach on vertex-centered unstructured grids for incompressible flow”, J. of Computational Physics 446 (2021): 110629

[5] A. Fick (1855): “Über Diffusion”, [https://doi.org/10.1002/andp.18551700105]

[6] Onda et al. (1968): “Mass Transfer Coefficients Between Gas and Liquid Phases in Packed Columns”, Journal of Chemical Engineering of Japan Vol.1 No.1

[7] P.V. Danckwerts (1971): „ Gas-liquid reactions”, McGraw-Hill Bock Co. [https://doi.org/10.1002/aic.690170204]

[8] Jäger et al. (2012): “Branched and linear poly(ethylene imine)-based conjugates: synthetic modification, characterization, and application“, Chem Soc Rev. 2012 Jul 7; 41(13):4755-67. [doi: 10.1039/c2cs35146c]