2024 AIChE Annual Meeting

(672g) Analysis of Polyethylene Pyrolysis Kinetics Using a Cost-Effective Rapid-Heating System: A 5-Lump Isothermal Study.

Authors

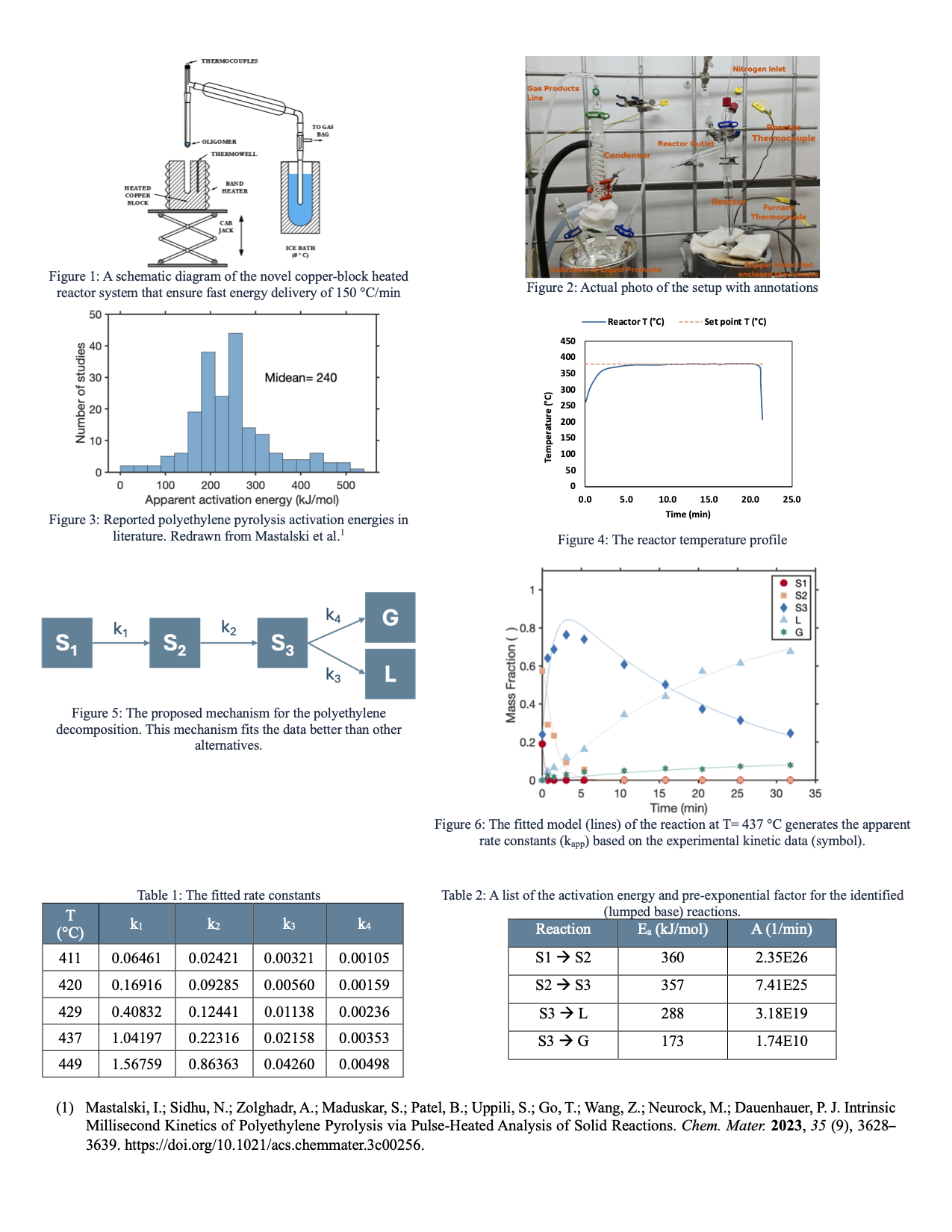

The design of pyrolysis reactors requires high-quality kinetic data. The literature has ∼200 kinetic data points for polyethylene pyrolysis with a wide distribution of activation energies of 42-533 kJ/mol. Most of these studies use non-isothermal data collected via thermal gravimetric techniques. Other literature uses batch systems to conduct isothermal kinetic studies, but most come with a long heating time of 20-120 min. The reactor choice regarding temperature gradient and thermal dwell time has the highest impact on these values. Therefore, studying true isothermal kinetics is challenging, as a significant polymer conversion would be reached before the isothermal temperature.

This paper presents a novel and affordable semi-batch reactor system heated by a thick copper-block designed to deliver energy at ∼125 °C/min. We used this system to measure the isothermal kinetic parameters of polyethylene decomposition using discrete lump methodology at temperatures of 411, 420, 429, 437, and 449 °C. We have identified five lumps that fit the kinetics data well: three representative polymer chains, liquid, and gas. The rate constants were fitted via an optimized solution of coupled ordinary differential equations. The activation energy and pre-exponential factor were found via the linearized form of the Arrhenius equation. The initial two decomposition steps have an apparent activation energy of ∼360 kJ/mol, matching the computational activation energy reported for the C-C homolysis. The net apparent activation energy of the four reactions amounts to 234 kJ/mol, very close to the non-isothermal thermal gravimetric result obtained in this study of 247 kJ/mol.