Electrochemical CO

2/CO reduction typically stops at C

2 to C

3 products, and it is getting extremely challenging to obtain high-value hydrocarbons that are longer than C

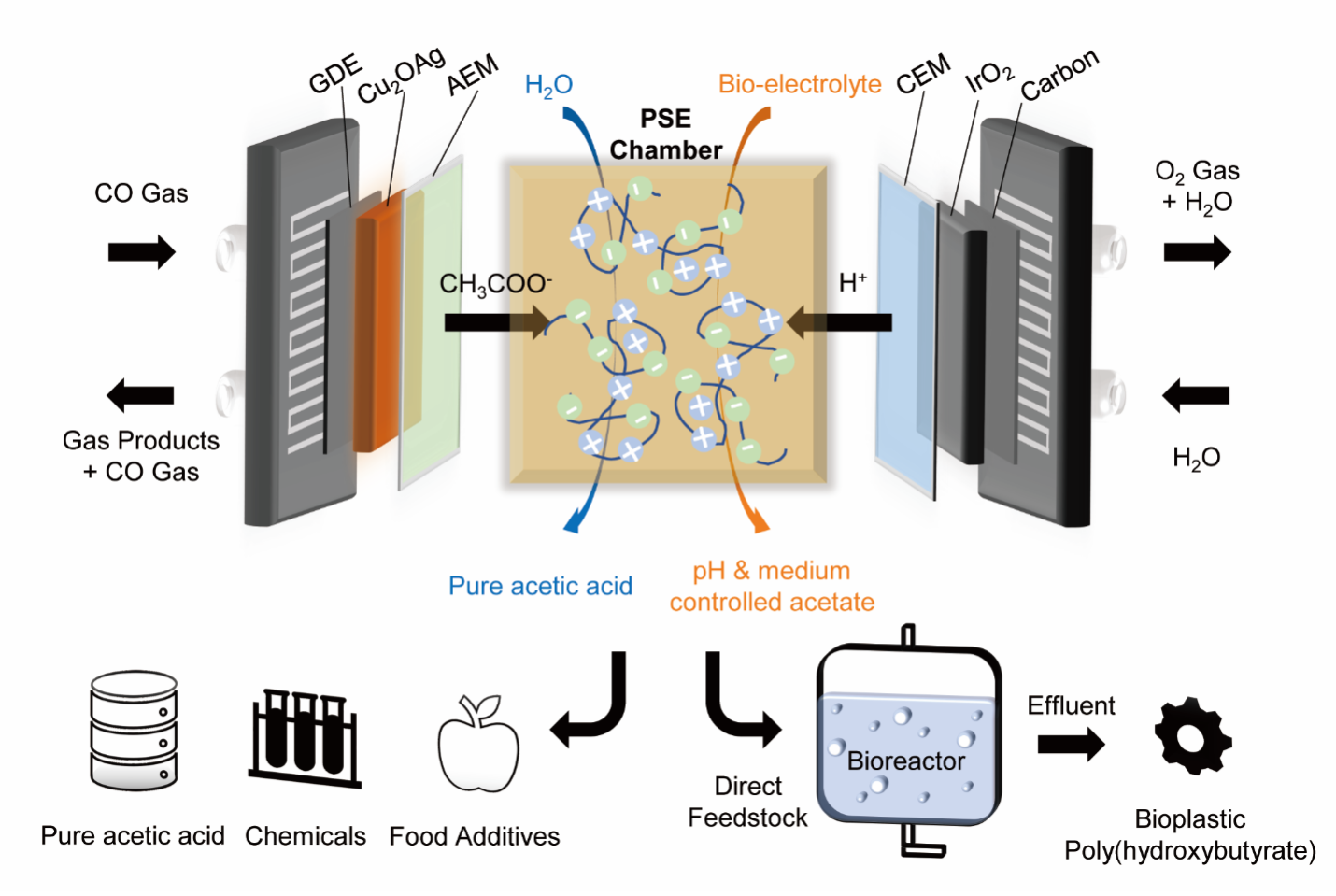

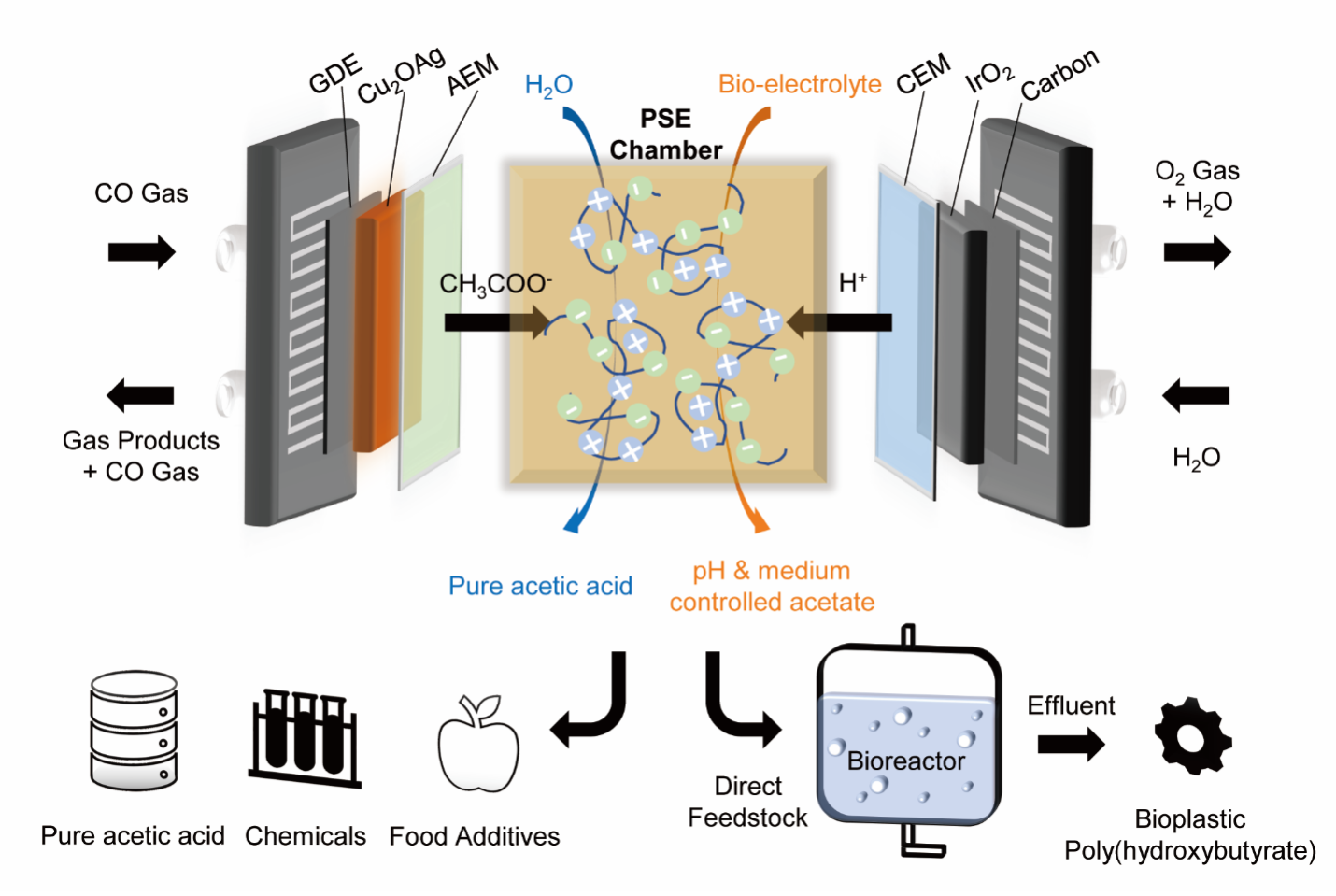

3. Integrating electrochemical CO

2/CO electrolyzers with a downstream bioreactor could help to obtain high-value long-chain products, but the electrolytes are mismatched in these two systems, preventing a smooth integration. Here, we demonstrated a porous solid electrolyte (PSE) electrolyzer that produced highly selective and pure acetate (~55% of FE

acetate with ~94 wt% of a relative purity) coupled with the biosynthesis system to generate C

4+ polyhydroxybutyrate (PHB) bioplastic. A finely tuned electrolyte containing proper salt medium with acetate can be directly injected into the downstream bioreactor without any separation or salt mixing processes. In this optimized coupled platform,

Ralstonia eutropha bacteria can grow with pure acetate generated from the electrocatalytic reactor using CO gas and produce bioplastic as the final value-added product. Using an optimized electrolyte,

Ralstonia eutropha efficiently converted acetate to 510 mg/L of C

4+ poly-hydroxybutyrate bioplastic, demonstrating carbon conversion efficiencies similar to bacteria cultivated on

simulated mineral salt medium.