Vegetable oils are prominent feedstocks in the chemical industry, offering renewable options to fossil-based fuels, chemicals and materials. Vegetable oils can be used to produce a variety of oleochemicals including fatty acids, fatty alcohols, esters, amines, epoxides and many other widely used in many applications. The versatility of vegetable oils as feedstock relies on their composition, mainly triglycerides of saturated and unsaturated fatty acids. In particular, unsaturations in the fatty acids of triglycerides are suitable active sites for different chemical transformations including hydrogenation, halogenation, sulfonation, hydroformylation, oxidative cleave and epoxidation, etc. [1]. In particular, epoxidized vegetable oils have garnered significant attention as upgrading strategy utilized as plasticizers for polymers, imparting plasticity, fluidity, and workability to various plastic products. Given the scrutiny surrounding conventional fossil-based phthalates plasticizers due to safety concerns, the demand for biobased, biocompatible, and renewable epoxidized vegetable oils is anticipated to surge, particularly in the expanding biopolymers market. Consequently, it is imperative to explore effective pathways for their synthesis.

Traditionally, epoxidized vegetable oils have been synthesized from highly unsaturated vegetable oils, primarily soybean, linseed, and sunflower. This industrial process is mainly carried out via the Prileschajew reaction, wherein the double bonds in the vegetable oil react with hydrogen peroxide (H2O2), utilizing a percarboxylic acid as an intermediate and an inorganic acid as homogeneous catalyst (e.g., sulfuric acid). While this method enables high conversions, the highly exothermic nature of epoxidation and long residence times also lead to oxirane ring degradation and product polymerization, resulting in low selectivity [2], [3]. Industrially, the reaction's selectivity typically does not exceed 80%, thus limiting the maximum oxirane ring content in commercial products [4]. This highlights the need to develop intensification approaches to control reaction temperature and to increase reaction conversion, selectivity and productivity towards epoxides in a continuous process.

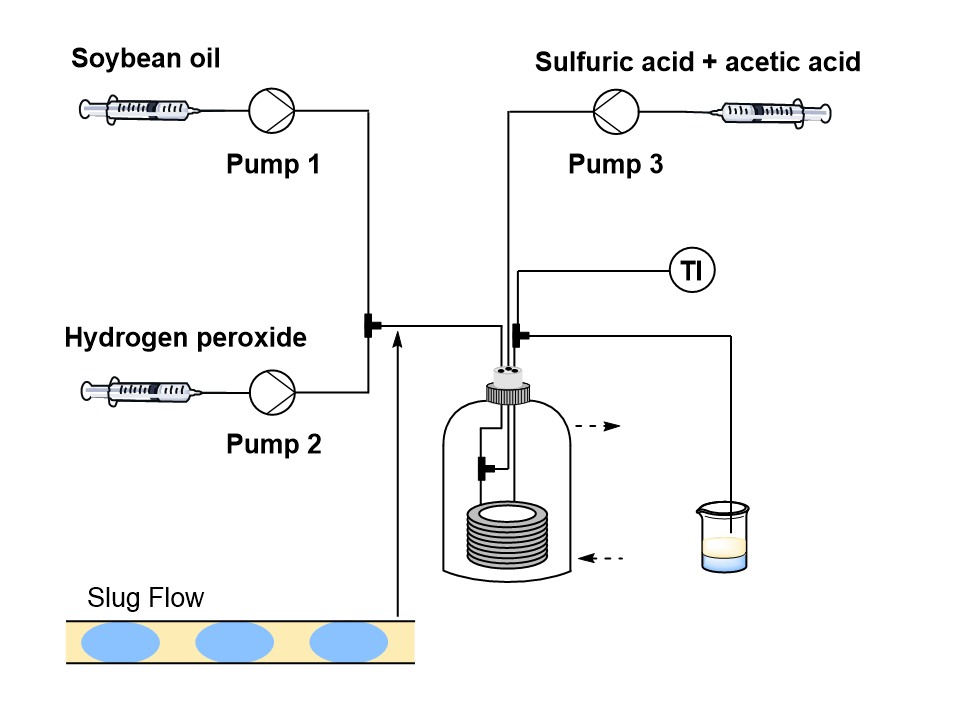

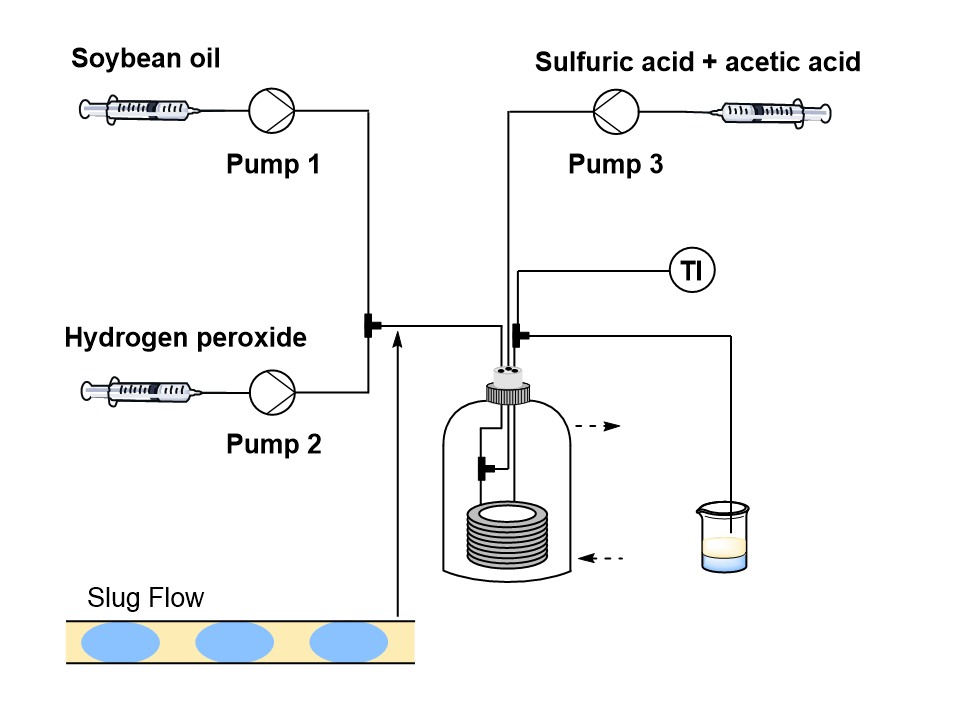

In this context, the use of continuous flow millireactor (Figure 1) has been evaluated in the epoxidation reaction with the aim of intensifying the process by controlling operational conditions and maximizing efficiency and selectivity. Millireactors, with their high surface-to-volume ratio, promote more efficient mass and heat transfer, resulting in shorter residence times and higher productivity compared to conventional reaction systems. In our study, various design conditions were evaluated in the millireactor, such as reactor length, stream configurations, curvature diameter of the reactor and feed conditions. Process efficiency was monitored by measuring iodine and oxirane values using hydrogen nuclear magnetic resonance spectroscopy (H-NMR). Finally, system optimization was carried out using the experimental implementation of a simplex method [5], varying operational conditions such as temperature, residence time, volumetric flow ratio of H2O2:oil, and volumetric flow ratio of acids (sulfuric acid and acetic acid) to oil (acids:oil). According to the obtained results, the best operating conditions were achieved at 69°C, with ratios of 0.79:1 for H2O2:oil and 0.29:1 for acids:oil, with a residence time of 30 minutes. These conditions resulted in a selectivity of 90% and productivity of 7.12 g/min, and an oxirane ring content of 6.4% wt. for soybean oil. These optimized operating conditions were also assessed for other vegetable oils, including canola, linseed, and sunflower with comparable yields and productivities. The obtained productivity was much larger to that observed in industrial batch processes also reducing required time for liquid-liquid separation of educts. In this regard, sets of parallel millireactors could become a suitable alternative for epoxidation of vegetable oils.

Figure 1. Scheme of the continuous slug-flow millireactor.

References

[1] G. Karmakar, P. Ghosh, K. Kohli, B. K. Sharma, and S. Z. Erhan, “Chemicals from Vegetable Oils, Fatty Derivatives, and Plant Biomass,” in ACS Symposium Series, 2020. doi: 10.1021/bk-2020-1347.ch001.

[2] S. C. Chua, X. Xu, and Z. Guo, “Emerging sustainable technology for epoxidation directed toward plant oil-based plasticizers,” Process Biochemistry, vol. 47, no. 10. 2012. doi: 10.1016/j.procbio.2012.05.025.

[3] P. L. Lee, W. M. Z. Wan Yunus, S. K. Yeong, D. K. Abdullah, and W. H. Lim, “Optimization of the epoxidation of methyl ester of palm fatty acid distillate,” J. Oil Palm Res., vol. 21, no. DECEMBER, 2009.

[4] S. Dinda, A. V. Patwardhan, V. V. Goud, and N. C. Pradhan, “Epoxidation of cottonseed oil by aqueous hydrogen peroxide catalysed by liquid inorganic acids,” Bioresour. Technol., vol. 99, no. 9, 2008, doi: 10.1016/j.biortech.2007.07.015.

[5] W. F. Bohórquez, A. Orjuela, P. C. Narvaez, J. G. Cadavid, J. A. García-Nunez,“Experimental optimization during epoxidation of a high-oleic palm oil using a simplex algorithm” Ind. Crops Prod. 187, 115321. https://doi.org/10.1016/j.indcrop.2022.115321