2024 AIChE Annual Meeting

(576i) Physics-Informed Machine Learning for CIP Optimization in Dairy Manufacturing

Authors

Protein fouling layers swell when they come into contact with alkaline cleaning solutions. Over time, chemical reactions soften the fouling near the liquid-solid interface by disrupting crosslinks. The resulting reacted protein dissolves into the flowing cleaning liquid at the interface, altering the fouling layer's density. This reduced cohesion within the fouling layer enables removal through applied shear force from the cleaning fluid flows. While reaction and removal occur near the interface, the alkaline agent diffuses and reacts towards the metal surfaces, i.e., equipment walls. Therefore, cleaning fouling layers from the metal surface involves a blend of mass transfer, chemical reaction, and mechanical abrasion.

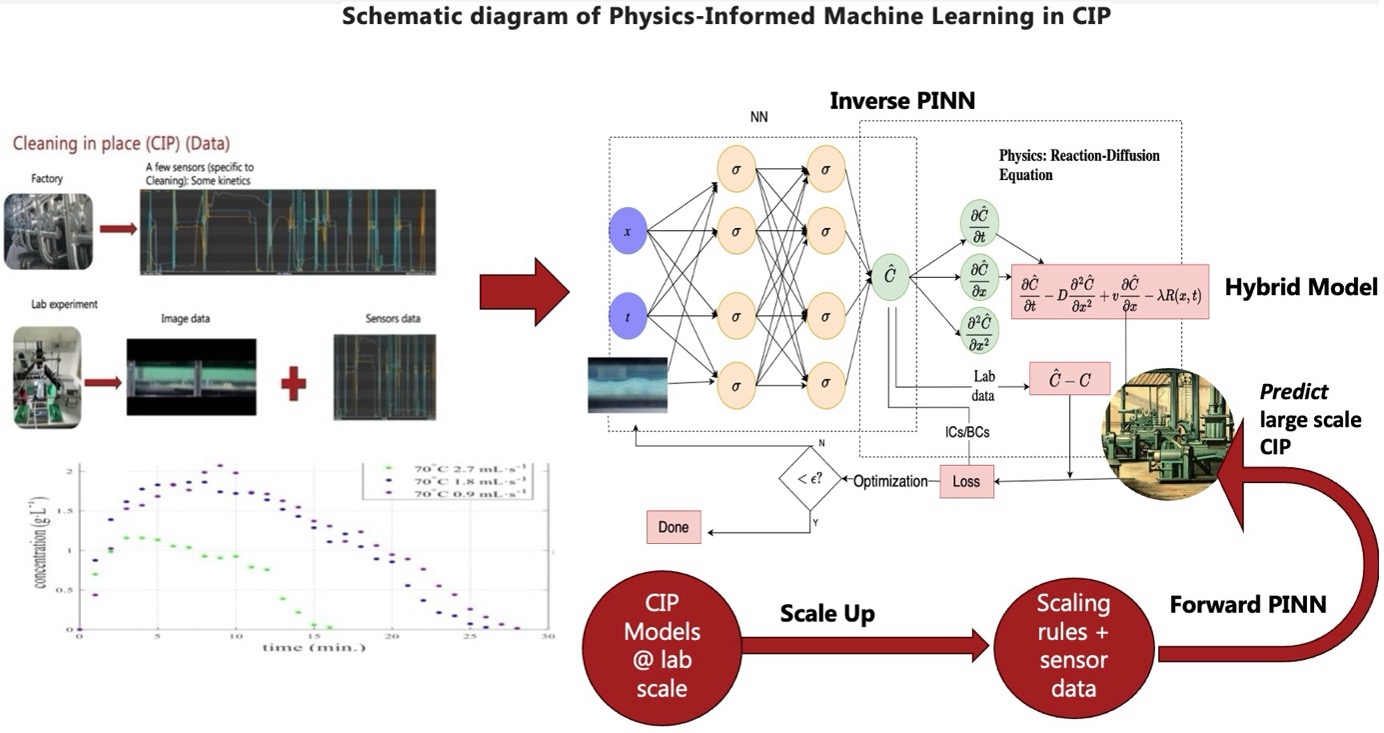

Our methodology involves integrating physics-informed machine learning techniques with laboratory experiments to analyze the cleaning kinetics of whey protein fouling layers in plate heat exchangers. Specifically, forward and inverse physics-informed neural networks are utilized, leveraging multimodal data and physics-based reaction diffusion equations to model and predict cleaning time. To the authors' knowledge, this is the first application of physics-informed machine learning in CIP optimization in the dairy industry.

Results demonstrate superior performance of the hybrid machine learning model compared to traditional data-driven approaches, showcasing scalability and retraining potential. This model offers enhanced efficiency in predicting cleaning time within dairy manufacturing processes. Our research thus addresses the critical problem of optimizing CIP processes in dairy manufacturing through innovative machine learning techniques. The implications of this study extend to improved sustainability, reduced resource consumption, and enhanced profitability in the dairy industry.