2024 AIChE Annual Meeting

(571k) CO2 Free Hydrogen Production Via Methane Pyrolysis Using a Moving Packed Bed Approach

Authors

Extensive research has been undertaken on hydrogen production, encompassing electrochemical, thermochemical, and biological pathways. This investigation is specifically centered on the thermochemical process of methane pyrolysis for hydrogen production.

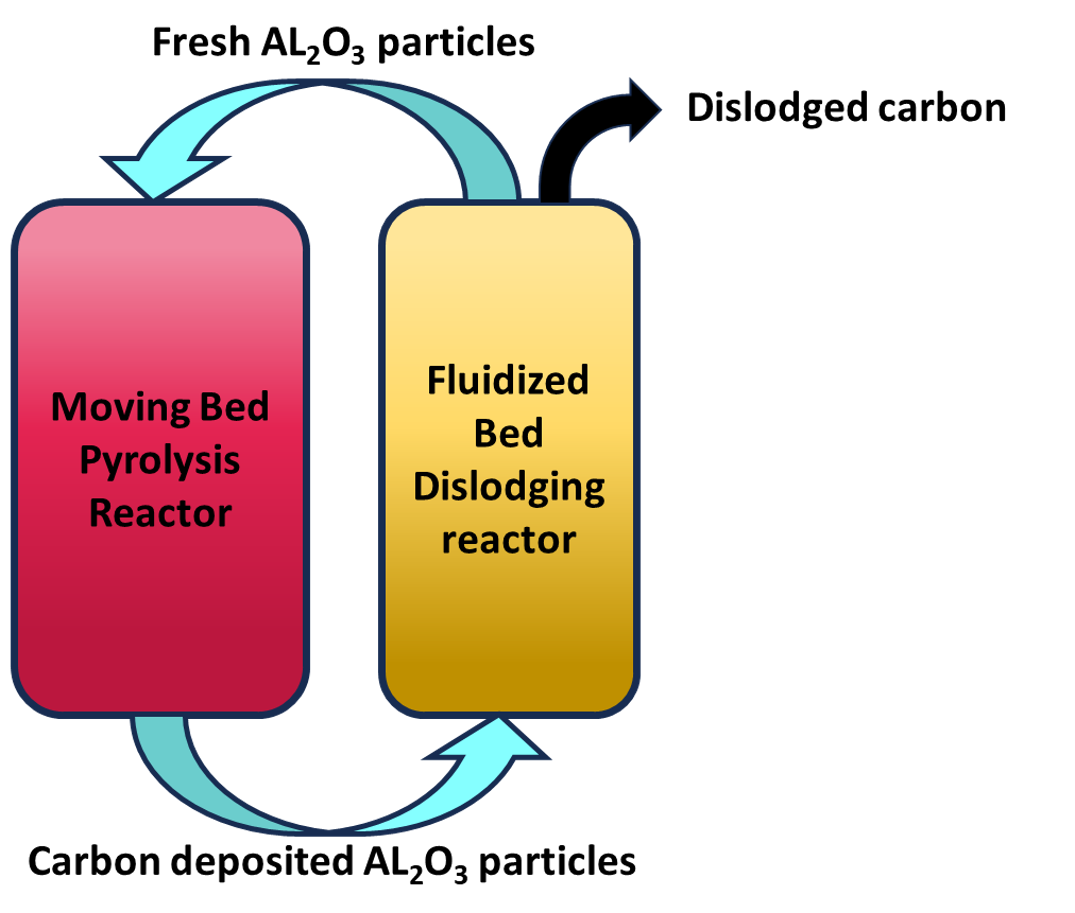

Methane pyrolysis entails the thermal cleavage of methane molecules into hydrogen and carbon. During methane pyrolysis, the thermal splitting of methane occurs within a reactor, where the methane molecules are subjected to elevated temperatures, typically exceeding 1000 °C. The resulting hydrogen is liberated in a gaseous state, while solid carbon is deposited on a catalyst material. Diligent efforts have been devoted to harnessing the deposited carbon through the catalytic generation of Carbon Nanotubes (CNTs), graphitic carbon, etc. The removal of this carbon is predominantly executed through a dislodging mechanism facilitated by a fluidized bed.

Currently, fluidized bed strategies are predominantly used in both methane pyrolysis and carbon dislodging. Our endeavor is to introduce a moving bed strategy for methane pyrolysis, enhancing control over reaction parameters to achieve heightened methane conversions and superior hydrogen purity. The current research focuses on elucidating the kinetics of the Methane Pyrolysis technology and its integration into a Technology Readiness Level (TRL) 5 process. The advancement pertaining to the dislodging of deposited carbon will be demonstrated at the TRL 5 level, employing two distinct strategies: one utilizing a moving bed system with lower gas velocities and the other operating in the pneumatic conveying regime of a fluidized bed system with higher gas velocities. Each strategy involves a unique gas-solid fluidization concept, differentiating the system from conventional approaches.

The resulting hydrogen exhibits high purity, rendering it suitable for diverse applications. Notably, due to its capacity to produce top-tier H2 without CO2 emissions, the integration of our process with carbon-intensive applications such as ammonia production and the steel industry holds the potential to mitigate the carbon intensity associated with these processes significantly.