2024 AIChE Annual Meeting

(569fg) Biomass Derived CO2-Rich Syngas Conversion to Fuels in 3D-Printed Stainless Steel (SS) Microreactor

Authors

Sujoy Bepari - Presenter, North Carolina A&T State University

Nafeezuddin Mohammad, Joint School of Nanoscience and Nanoengineering, NC A&T State University

Jeremy Feaster, Lawrence Livermore National Laboratory

Debasish Kuila, North Carolina A&T State University

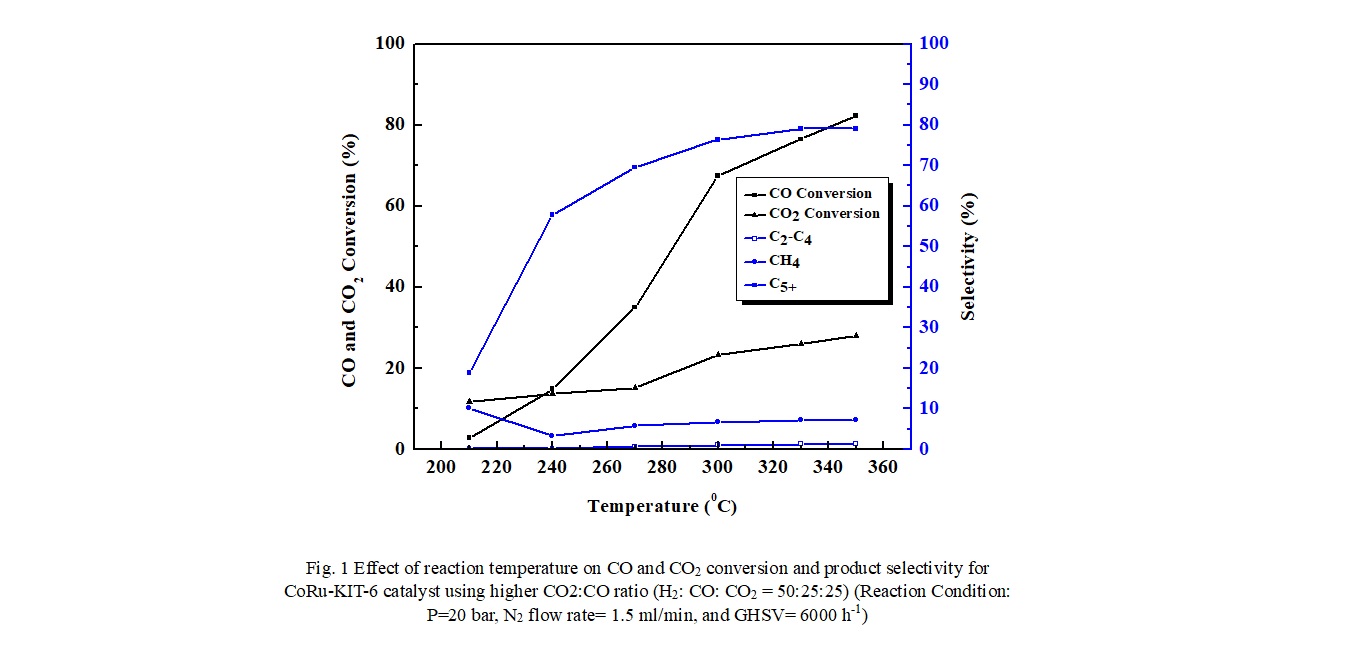

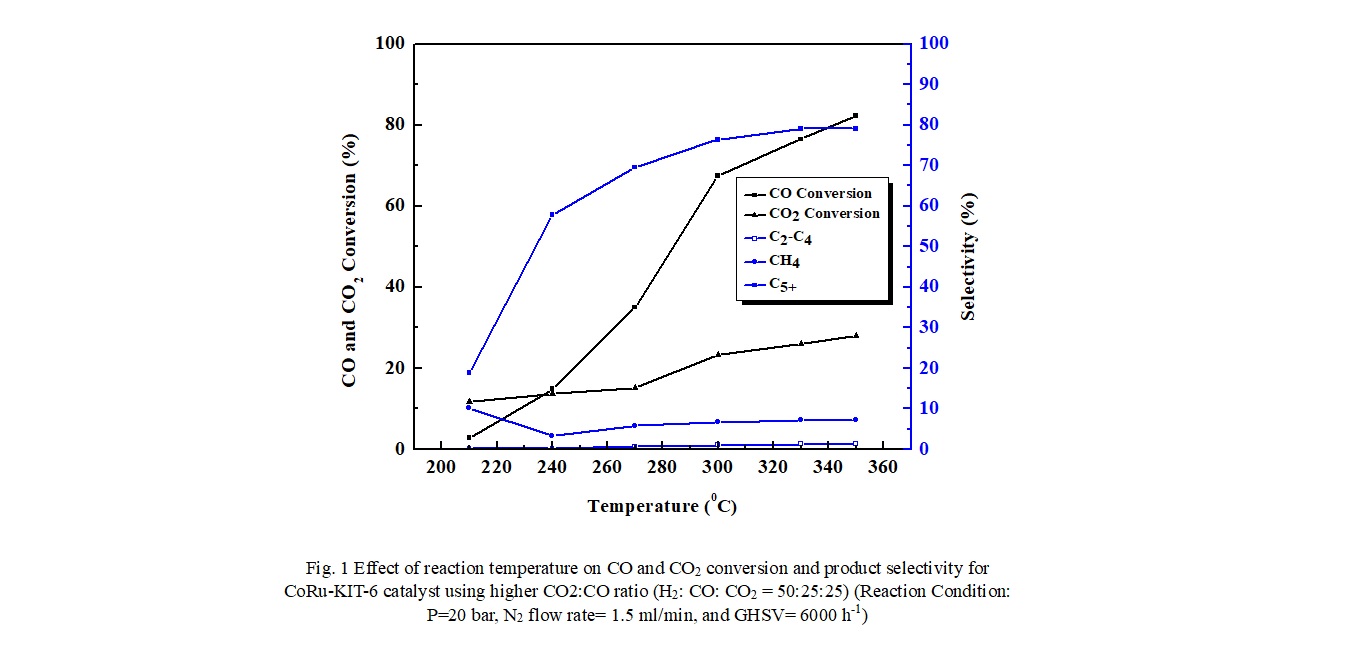

The CoRu-KIT-6 catalyst, synthesized via a one-pot hydrothermal approach, was employed in Fischer-Tropsch Synthesis (FTS) of syngas containing CO2 at 20 bar in a microreactor fabricated via 3D printing. Various characterization techniques, including N2 adsorption-desorption, Scanning Electron Microscopy (SEM), Transmission Electron Microscopy (TEM), X-ray diffraction (XRD), H2-Temperature programmed reduction (H2-TPR), and X-ray photoelectron spectroscopy (XPS), were utilized to analyze the catalyst. The catalyst exhibited a considerable BET surface area (N2 adsorption-desorption) alongside low reduction temperatures (H2-TPR) for the metals. Moreover, low-angle XRD, SEM, and TEM investigations revealed the preservation of KIT-6's mesoporous silica structure after metal incorporation. The XPS findings were supported by H2-TPR analysis. Four distinct compositions of CO2/CO/H2 were employed for tailored F-T synthesis. As the reaction temperature increased, CO2 conversion rose, while CO conversion was influenced by the CO2 quantity in the gas feed mixtures. The catalyst demonstrated exceptional catalytic performance in terms of CO conversion. The CO2-rich syngas composition (CO2:CO: H2=25:25:50) showed the best result in terms of conversion and hydrocarbon selectivity.